Method for strengthening short-cut nitrification reactor by embedded cathode dynamic membrane

A short-range nitrification and reactor technology, applied in chemical instruments and methods, electrochemical biological combination treatment, sustainable biological treatment, etc., can solve the problems of slow growth and restriction of engineering application, increase the content of bacteria, solve the problem of microbial Loss, overcoming the effect of fast membrane fouling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

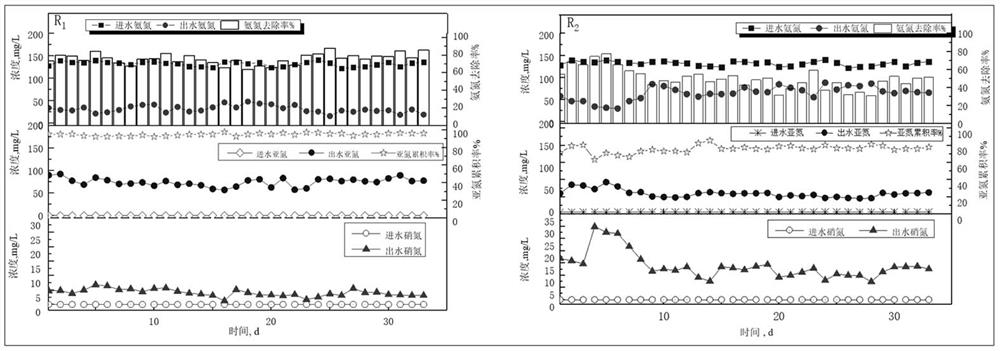

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0025] This embodiment provides a method for a short-path nitrification reactor with an embedded cathode dynamic membrane, which includes the following steps:

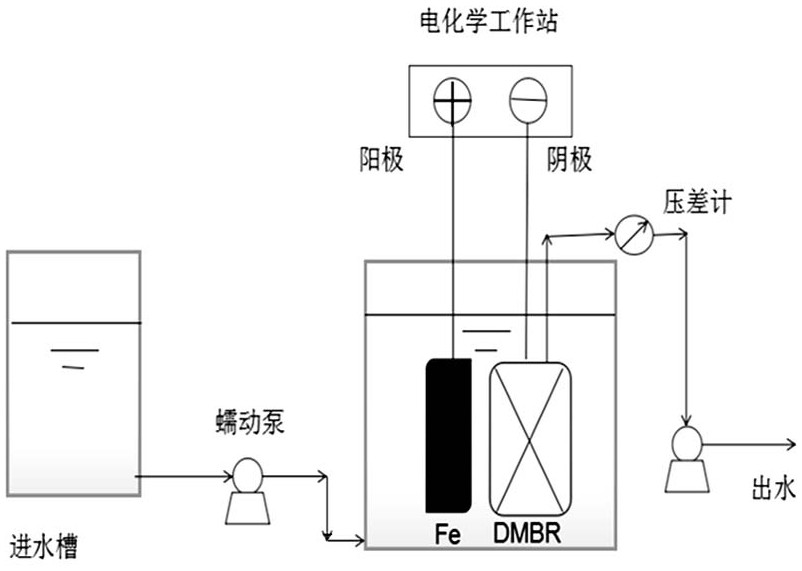

[0026] Prepare continuous flow reactor, domesticated short-range nitrification sludge, dynamic membrane module, iron plate, electrochemical workstation, water inlet tank, peristaltic pump, aeration pump, differential pressure gauge and outlet pump.

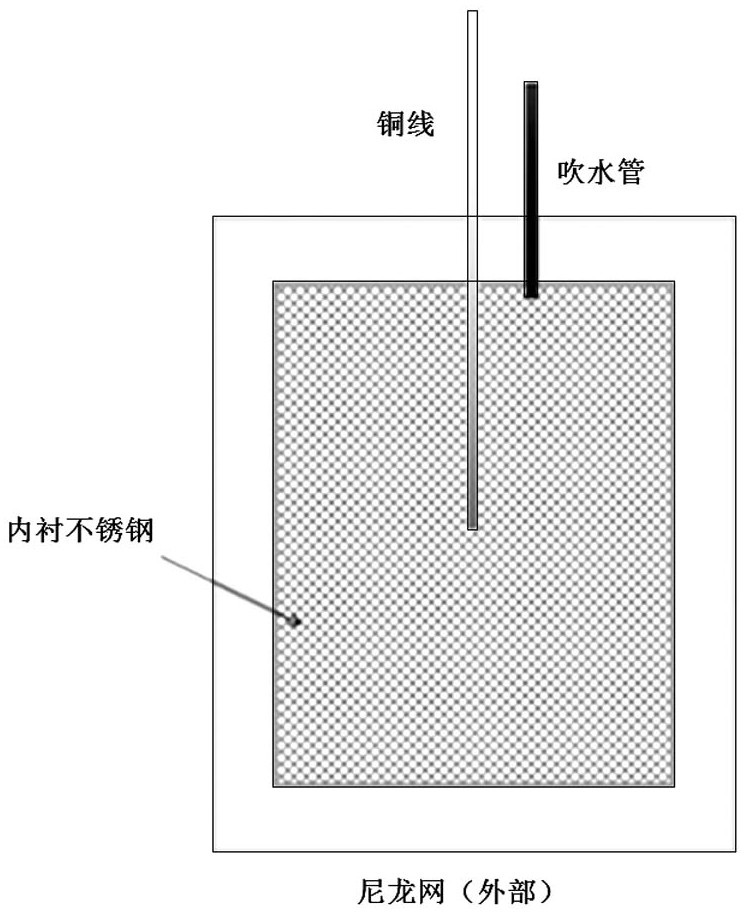

[0027] The dynamic membrane module is installed in the continuous flow reactor, the stainless steel lining is used as the cathode in the dynamic membrane module, the iron plate is used as the anode, and the cathode and the anode are respectively connected to the electrochemical workstation.

[0028] The aeration pump is set in the continuous flow reactor, and the prepared short-path nitrification sludge is added to make the concen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com