Method for operating hydraulic drive

A technology of hydraulic drives and hydraulic consumers, applied in the field of computer programs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

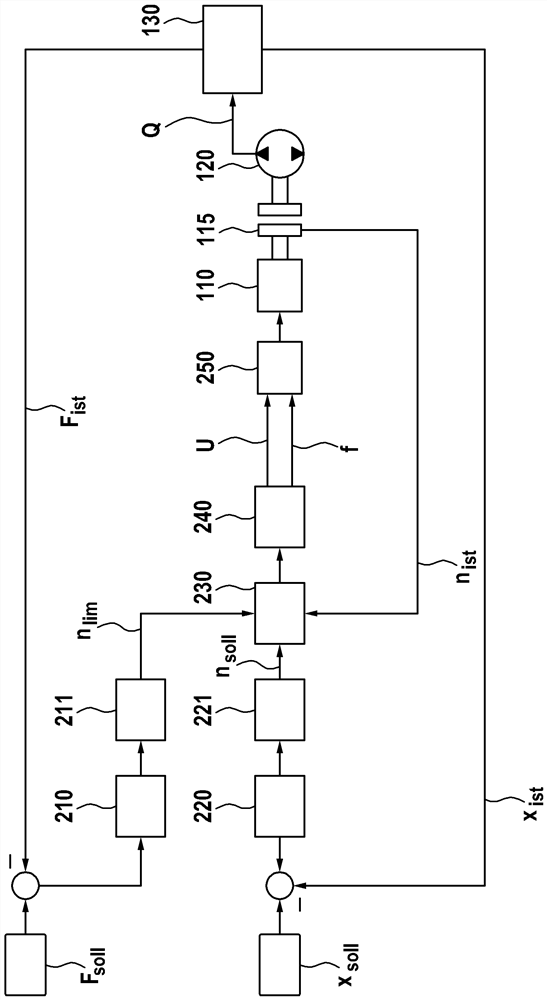

[0031] figure 1 A hydraulic drive 100 in which the method according to the invention can be carried out is shown schematically in FIG. The hydraulic drive 100 currently has a variable-speed electric motor or drive 110 with a stator 111 and a rotor 112 which is connected via a clutch 115 to a hydraulic pump 120 . The hydraulic pump 120 is an axial piston pump embodied as a fixed displacement pump, which has a fixed transport volume in each working gap. The hydraulic pump 120 can be driven variably by the rotational speed by means of the electric motor 110 .

[0032]Furthermore, the hydraulic pump 120 is connected to a hydraulic consumer 130 with positionable elements. The hydraulic consumer 130 is currently designed as a cylinder with a piston as a positionable element, wherein the piston has, for example, a piston rod on both ends. The hydraulic pump 120 is connected to the cylinder at both ends, so that a movement of the piston in both directions is possible depending on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com