Combustor adjusting method and system based on temperature field, DCS (Distributed Control System) and medium

An adjustment method and burner technology, applied in the direction of combustion method, combustion control, fuel supply adjustment, etc., can solve problems such as polluting the environment, affecting the combustion efficiency of the furnace, and uneven temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

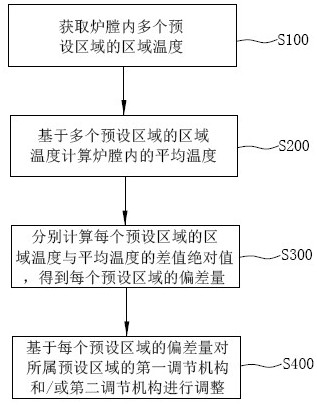

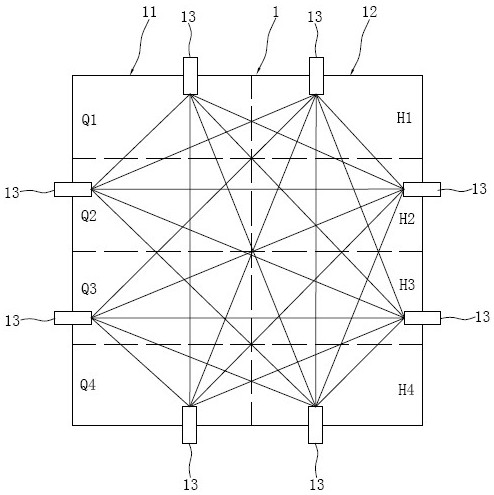

[0090] The following is attached Figure 1-15 The application is described in further detail.

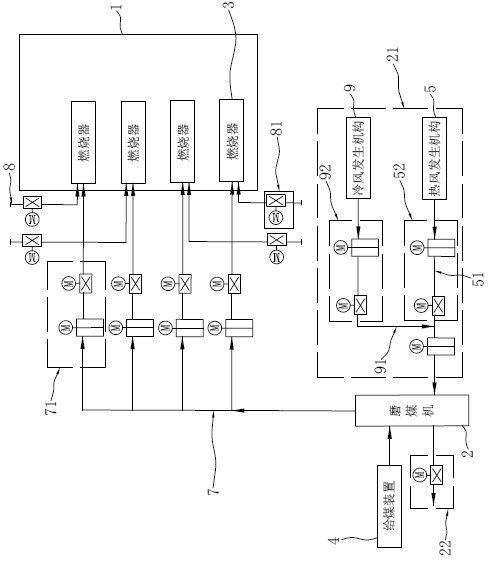

[0091] The embodiment of the present application discloses a boiler combustion system, referring to figure 1 , the system includes a boiler furnace 1 and a coal mill 2, and a plurality of burners 3 are installed in the furnace 1; the coal mill 2 includes a plurality of feed ports and a plurality of discharge ports, and one of the feed ports communicates with a Coal feeding device 4 for transporting coal to coal mill 2, coal mill 2 grinds coal into coal powder, and another feed port is connected with air supply device 21 for blowing wind into coal mill 2, wind and The air-powder mixture composed of pulverized coal is delivered to the burner 3 from the discharge port of the coal mill 2 .

[0092] A plurality of first pipelines 7 are connected to the outlet of the coal mill 2, and the first pipelines 7 are connected to the burner 3. The first pipeline 7 is equipped with a first adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com