Raw material stirring and drying device for new material production

A technology of drying device and new material, applied in drying, drying machine, heating device and other directions, can solve the problems of low efficiency, time-consuming and labor-intensive, and achieve the effect of good drying effect, improving work efficiency and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

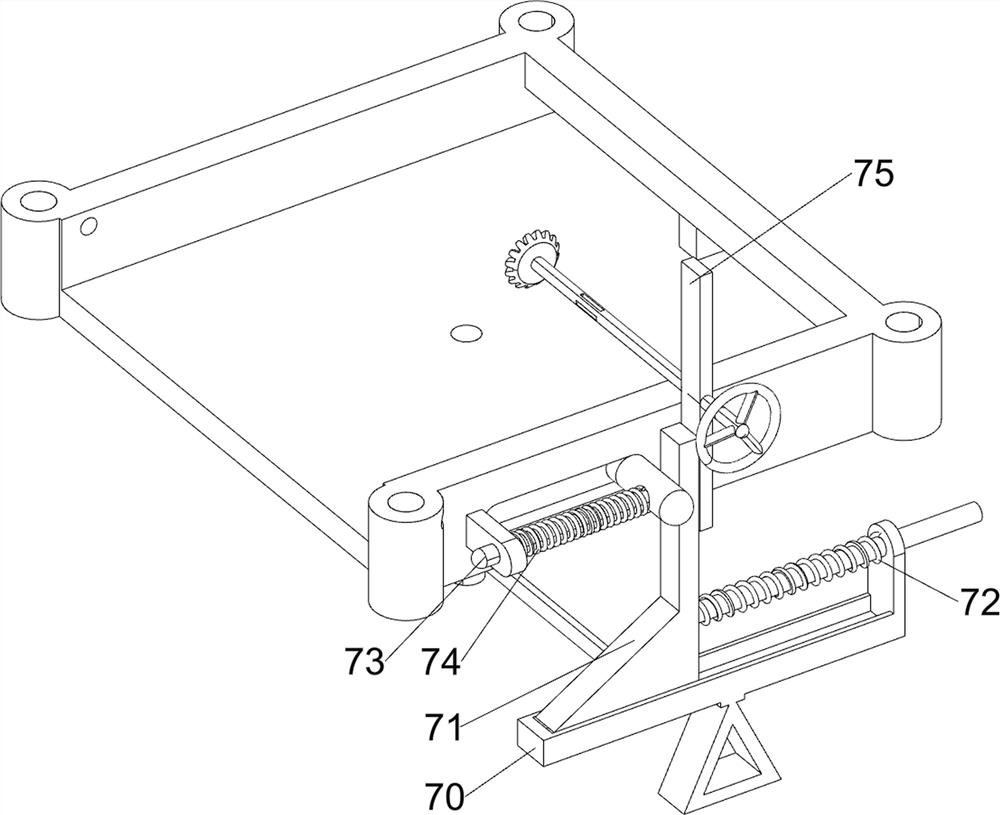

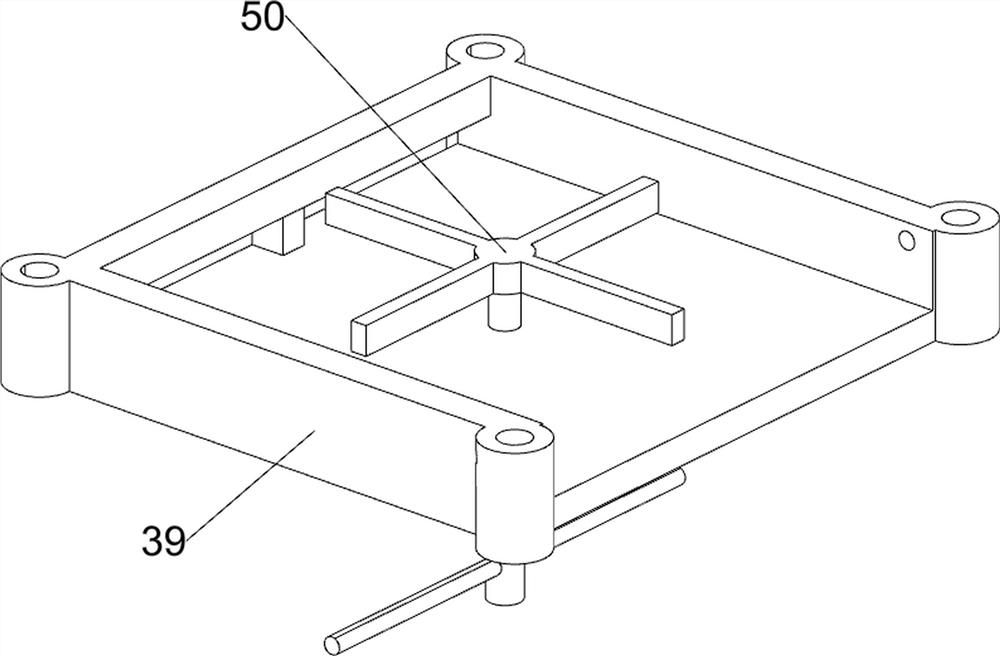

[0035] A raw material stirring and drying device for the production of new materials, such as Figure 1-3 As shown, it includes a base 1 , a drying mechanism 2 and a stirring mechanism 3 , the drying mechanism 2 is connected to the top of the base 1 , and the stirring mechanism 3 is connected to the left side of the top of the base 1 .

[0036] The drying mechanism 2 includes an installation frame 20, a touch switch 21 and a heating roller 22. The top of the base 1 is connected with the installation frame 20, the left front side of the installation frame 20 is provided with a touch switch 21, and the inside of the installation frame 20 is provided with a heating roller. 22. The heating roller 22 cooperates with the touch switch 21.

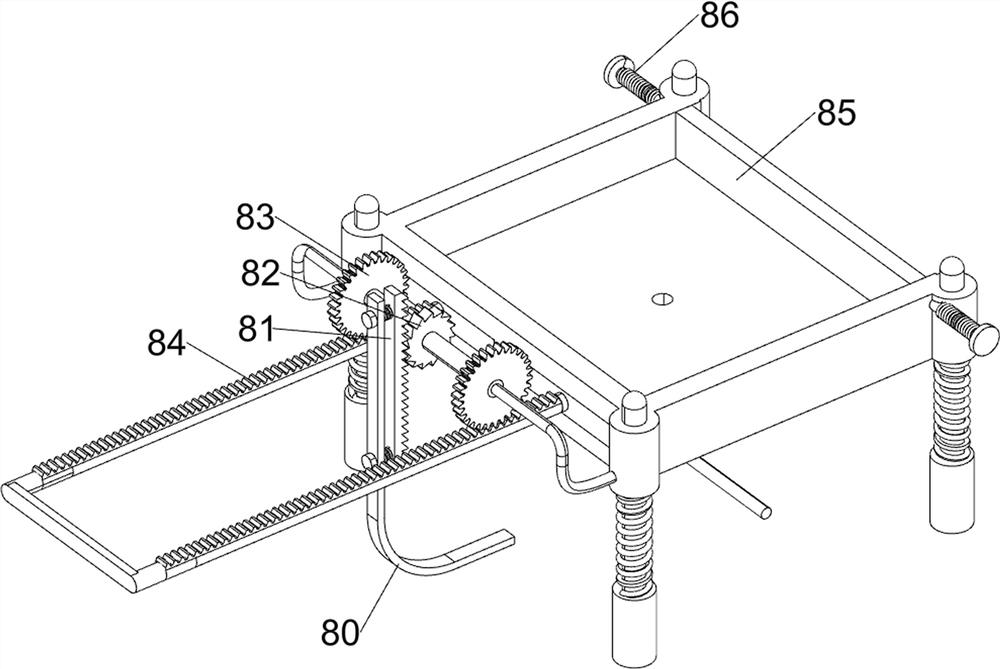

[0037] The stirring mechanism 3 includes a first support rod 30, a container 31, a servo motor 32, a stirring rod 33, a rotary switch 34, a connecting rod 35, a rotating shaft 36, a first bevel gear 37, a second bevel gear 38, and a first collecti...

Embodiment 2

[0040] On the basis of Example 1, such as Figure 4 As shown, it also includes a locking mechanism 4, and the locking mechanism 4 includes a first spring 40 and a locking lever 41. The lower part of the connecting rod 35 is slidably connected with the locking lever 41, and the locking lever 41 cooperates with the rotating shaft 36. A first spring 40 is connected between the connecting rods 35 .

[0041] When manually turning the rotating shaft 36 to carry out blanking and drying to the raw materials that have been stirred, the manually rotating rotating shaft 36 drives the clamping lever 41 to move upwards, and the clamping lever 41 moves upwards and the first spring 40 is compressed. When the slots overlap, the clamping lever 41 resets under the action of the compressed first spring 40, so that the angle of rotation can be controlled manually when the rotating shaft 36 is rotated to achieve an auxiliary effect.

Embodiment 3

[0043] On the basis of Example 2, such as Figure 5 and Figure 6 As shown, it also includes a paving mechanism 5. The paving mechanism 5 includes a blade 50, a nut 51, a second support rod 52 and a tank tube 53. The middle of the first collection frame 39 is rotationally connected with the blade 50, and the mounting frame 20 A nut 51 is connected to the inner left side, a second support rod 52 is connected between the front and rear sides of the nut 51 and the installation frame 20 , and a grooved cylinder 53 is connected to the bottom of the blade 50 , and the grooved cylinder 53 cooperates with the nut 51 .

[0044] When the first collecting frame 39 moves downward, the downward movement of the first collecting frame 39 drives the blade 50 to move downward, and the downward movement of the blade 50 drives the groove cylinder 53 to move downward, and the downward movement of the groove cylinder 53 cooperates with the nut 51 Rotate, the groove drum 53 rotates so that the raw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com