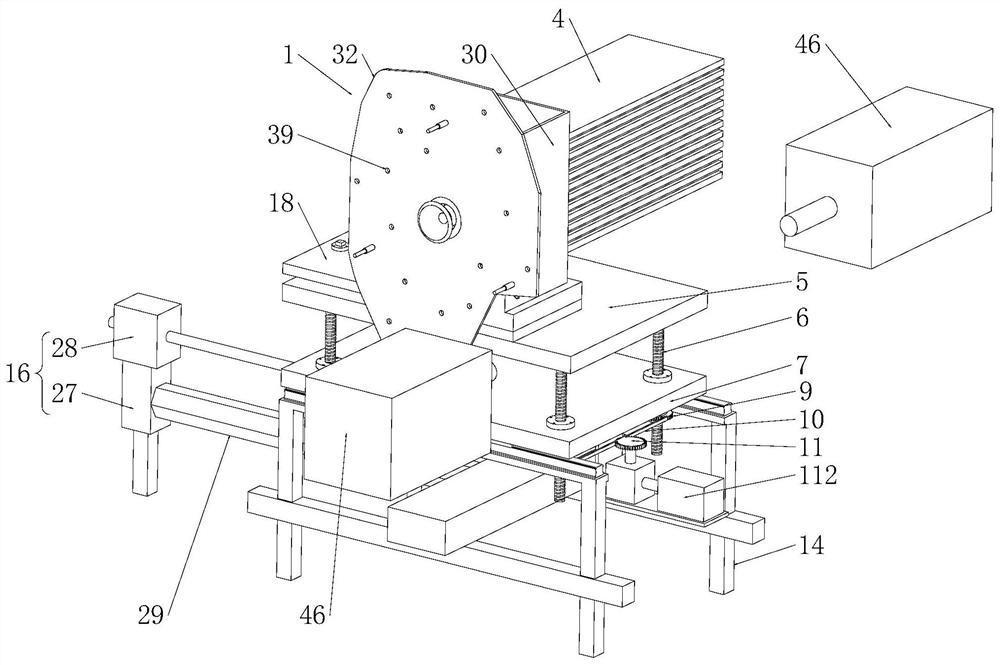

Gearbox simulation detection equipment

A technology for testing equipment and gearboxes, which is applied in the field of gearbox simulation testing equipment, can solve problems such as poor versatility, and achieve the effects of reduced volume, reduced processing difficulty, and improved versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

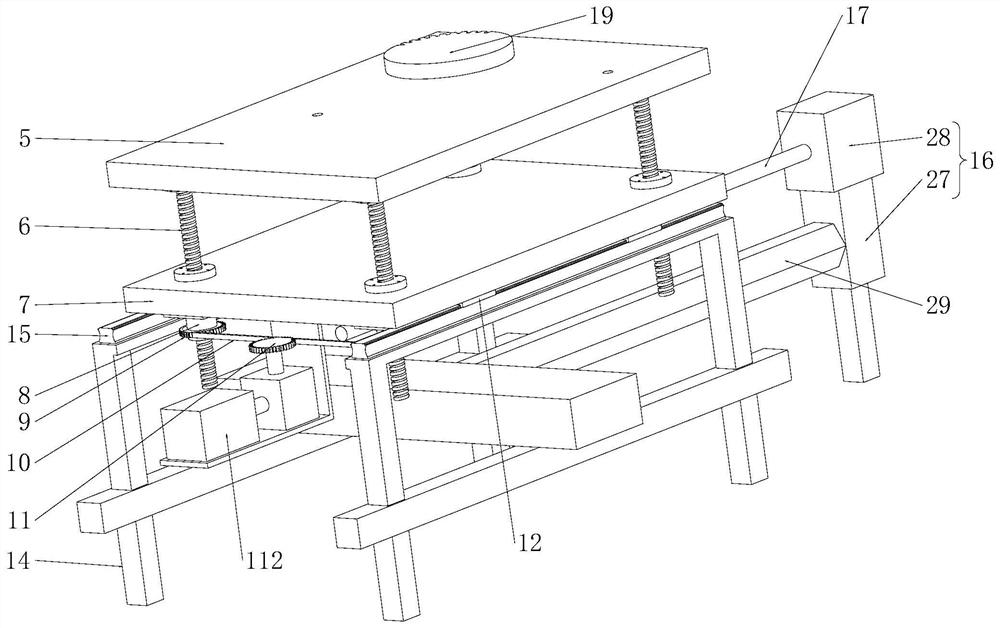

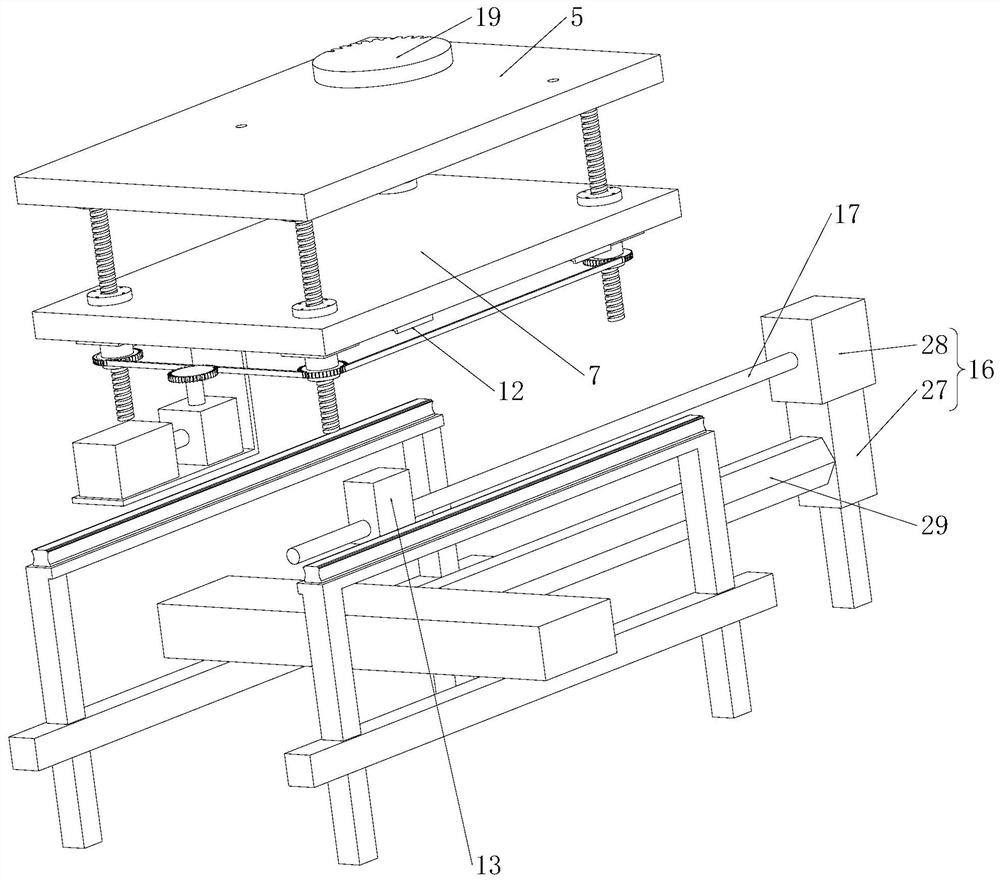

[0047] see Figure 7 , The gearbox simulation detection device also includes a swing seat 18, the swing seat 18 is sandwiched between the lifting plate 5 and the main chassis 1, and is supported by the lifting plate 5 and supports the main chassis 1.

[0048] The lifting plate 5 is fixed with a stationary sun gear 19, the sun gear 19 is placed horizontally, the swing seat 18 is pivotally connected with the sun gear 19 through the first pivot shaft, the axis of the first pivot shaft is collinear with the axis of the sun gear 19, and the swing seat 18 is connected via a second pivot shaft with a planetary gear 20 , which meshes with the sun gear 19 . Set up in this way, the main chassis 1 supported by the swing seat 18 can follow the swing of the swing seat 18, thereby further adjusting the orientation of the gearbox, so that the output shafts of different gearboxes can be docked with the rotating shaft of the load system 46, that is, further The versatility of the transmission...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com