A small internal combustion engine crankshaft system simulation device and simulation method

A system simulation, internal combustion engine technology, applied in the direction of internal combustion engine testing, etc., can solve the problems of inconsistent driving action, inaccurate axis trajectory, and failure to satisfy the equivalence of the internal combustion engine crankshaft system, etc., to achieve the effect of satisfying equivalence and accurate research results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

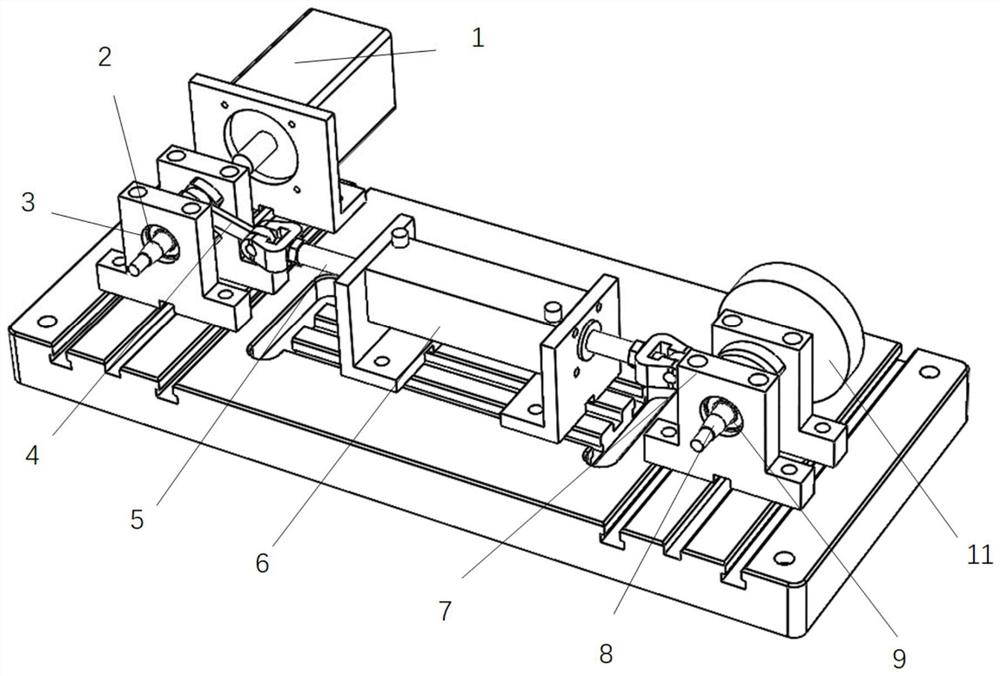

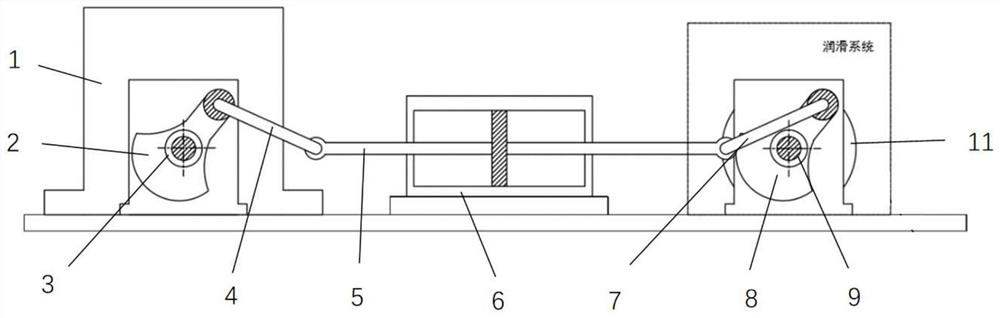

[0035] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0036] This embodiment provides a small internal combustion engine crankshaft system simulation device, see the attached Figure 1-2 , comprising: an installation platform, a loading system, a double-head cylinder 6 and an execution system; the loading system, the double-head cylinder 6 and the execution system are all installed on the installation platform, wherein the double-head cylinder 6 is located between the loading system and between execution systems;

[0037] The loading system includes: a servo motor 1, a driving crankshaft 2, a rolling bearing 3 and a left connecting rod 4;

[0038] The execution system includes: right connecting rod 7, driven crankshaft 8, sliding bearing 9 and flywheel 11;

[0039] Described double-headed cylinder 6 is provided with piston, and the two ends of piston are all provided with piston rod 5, makes two piston rods...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com