Treatment method of recommissioned radioactive nuclear graphite

A processing method and radionuclide technology, applied in the field of radioactive graphite processing, can solve problems such as environmental and human harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

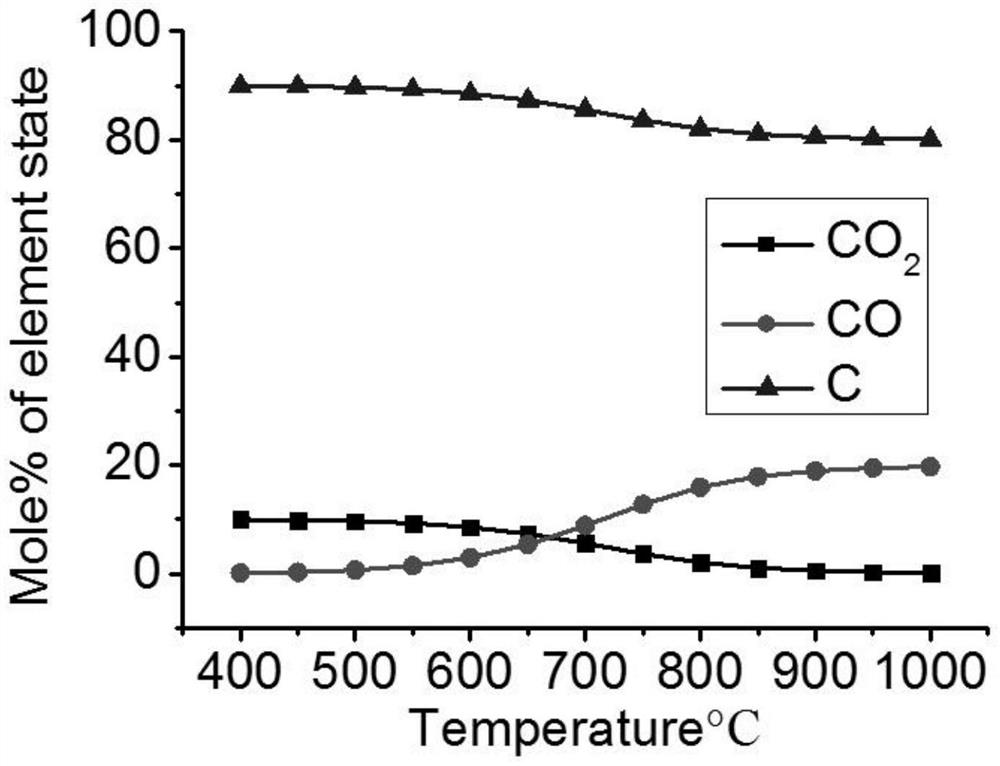

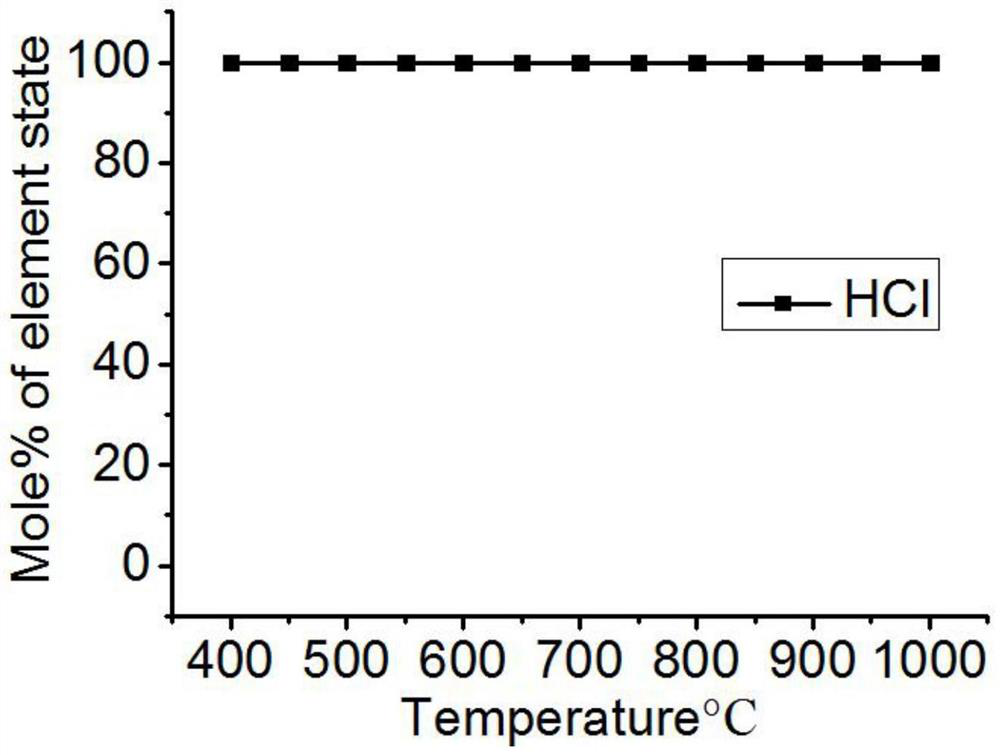

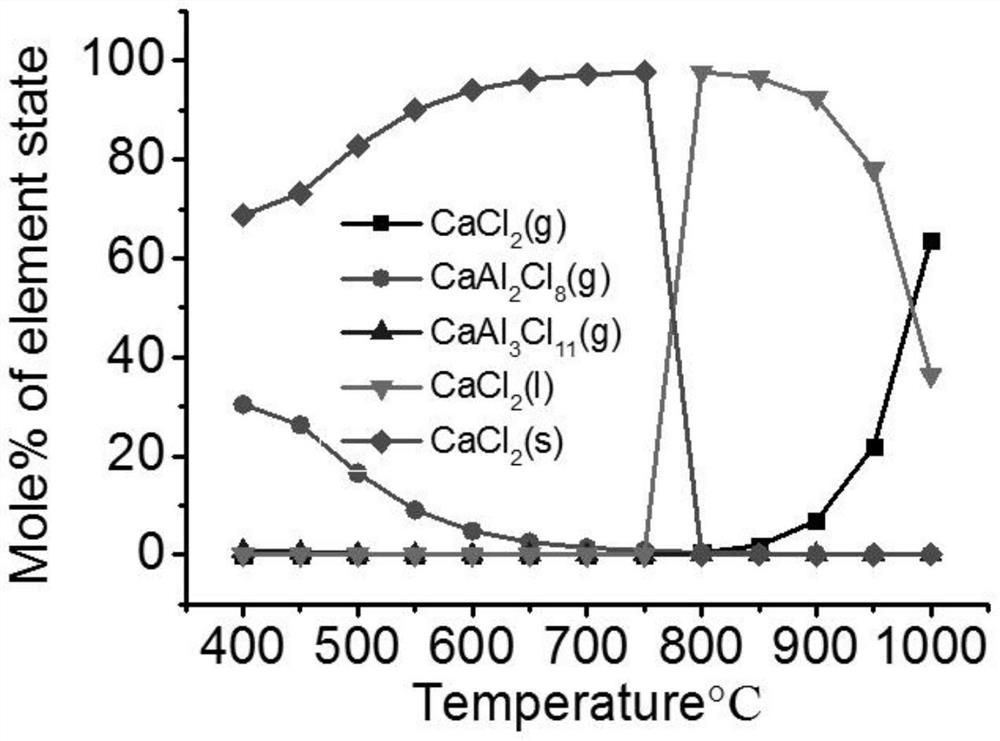

[0033] Take 10g of nuclear graphite and pulverize it into a powder smaller than 250um after being pulverized by a disc mill, weigh 1%wt analytical pure AlCl 3 Mix with nuclear graphite powder, the mixing method is planetary ball mill, the speed is 180r / min, the mixing time is 1h, the heat treatment is carried out in a tube furnace, the temperature is 800°C, the heating rate is 10°C / min, and the atmosphere is 90% argon Gas+10%O 2 , the gas flow rate is 100ml / min. After the temperature rises to the specified temperature, quickly put the crucible containing the mixed powder into it, and the heating time is 2 hours. The heat treatment equipment is connected with a condensation device, so that the temperature of the volatilized metal chloride drops below the dew point and condenses as After the particles are collected, the decontamination of the radioactive metal isotopes in the nuclear graphite is completed. The equipment is connected with an alkali washing pool and condensation e...

Embodiment 2

[0035] The treatment method of the decommissioned radioactive graphite in this embodiment is the same as in the first embodiment, except that the heat treatment temperature is 900°C.

Embodiment 3

[0037] The processing method of the decommissioned radioactive graphite in this embodiment is the same as that in Embodiment 1, except that the heat treatment temperature is 1000°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com