Treatment method of sulfuric acid high arsenic and thallium acid wastewater

A technology of acidic wastewater and treatment method, which is applied in the treatment of thallium acidic wastewater and the field of high arsenic in sulfuric acid, which can solve the problems of unstable treatment effect and high treatment cost of sulfuric acid acidic wastewater, making it easy for employees to master, strong operability, simple and clear operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

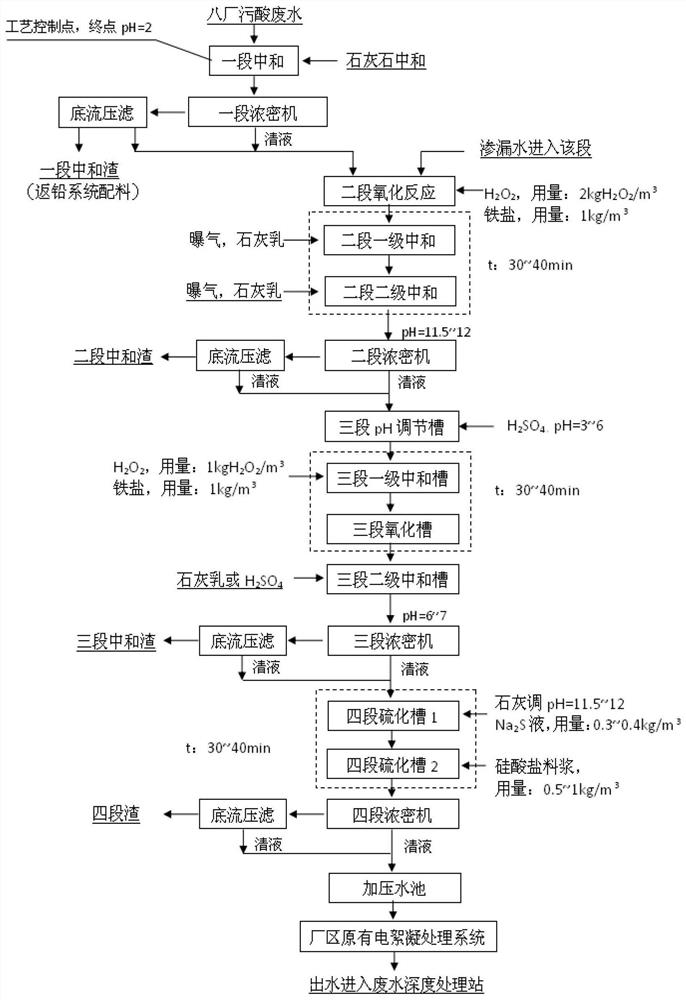

[0027] Refer to attached figure 1 , the treatment method of sulfuric acid high arsenic, thallium acidic waste water, comprises the following steps:

[0028] Add limestone to the sewage for neutralization, the control condition is that the pH end point is 2, enter the first-stage thickener, and press the bottom flow to obtain a first-stage neutralization slag, add permeate water into the clear liquid to enter the second-stage oxidation reaction, add hydrogen peroxide 2kg / m 3 and iron salt 1kg / m 3 , and then go through the second-stage and second-stage neutralization, the first-stage neutralization and the second-stage neutralization are respectively added with milk of lime and aerated for 30 minutes. After neutralization, the pH of the liquid is 11.5, and it enters the second-stage thickener. Press filtration to obtain the second-stage neutralization slag, and the clear liquid enters the three-stage pH adjustment tank successively. In the three-stage pH adjustment tank, there ...

Embodiment 2

[0030] Refer to attached figure 1 , the treatment method of sulfuric acid high arsenic, thallium acidic waste water, comprises the following steps:

[0031] Add limestone to the sewage for neutralization, the control condition is that the pH end point is 2, enter the first-stage thickener, and press the bottom flow to obtain a first-stage neutralization slag, add permeate water into the clear liquid to enter the second-stage oxidation reaction, add hydrogen peroxide 2kg / m 3 and iron salt 1kg / m 3 , and then go through the second-stage and second-stage neutralization, the first-stage neutralization and the second-stage neutralization are respectively added with milk of lime and aerated for 40 minutes. After neutralization, the pH of the liquid is 12, and it enters the second-stage thickener. Press filtration to obtain the second-stage neutralization slag, and the clear liquid enters the three-stage pH adjustment tank successively. In the three-stage pH adjustment tank, there is...

Embodiment 3

[0033] Refer to attached figure 1 , the treatment method of sulfuric acid high arsenic, thallium acidic waste water, comprises the following steps:

[0034] Add limestone to the sewage for neutralization, the control condition is that the pH end point is 2, enter the first-stage thickener, and press the bottom flow to obtain a first-stage neutralization slag, add permeate water into the clear liquid to enter the second-stage oxidation reaction, add hydrogen peroxide 2kg / m 3 and iron salt 1kg / m 3 , and then after two stages of secondary neutralization, lime milk is added to the primary neutralization and secondary neutralization and aerated for 30-40 minutes respectively. After neutralization, the pH of the liquid is 11.7, and it enters the second stage thickener , underflow pressure filtration, to obtain the second-stage neutralization slag, and the clear liquid enters the three-stage pH adjustment tank successively. In the three-stage pH adjustment tank, there is a sulfuric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com