Volumetric gas-liquid two-phase flow meter and measuring method thereof

A volumetric and flowmeter technology, which is applied in volumetric measuring instruments/methods, liquid/fluid solid measurement, volume measurement, etc., can solve the problem of high imaging processing cost, differential pressure flowmeter, inability to detect gas-liquid two-phase mixed fluid flow, etc. problems, to achieve the effect of reducing equipment volume and cost, light weight, safe and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

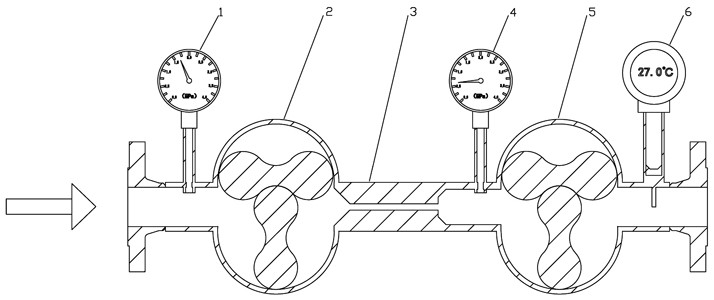

[0027] Embodiment one, as attached figure 1 As shown, the volumetric gas-liquid two-phase flowmeter includes a first volumetric flowmeter 2, a second volumetric flowmeter 5, a first pressure transmitter 1, a second pressure transmitter 4 and a differential pressure tube 3, The first positive displacement flowmeter 2, the differential pressure pipe 3 and the second positive displacement flowmeter 5 are fixed together in sequence, the first pressure transmitter 1 is installed on the left end of the first positive displacement flowmeter 2, and the second positive displacement flowmeter A second pressure transmitter 4 is installed at the left end of the gauge 5 .

[0028] During use, positive displacement flowmeters do not need to have long straight pipe sections before and after to form a stable flow velocity distribution in the pipe. There is no requirement for the velocity distribution in the pipe, which brings great convenience to on-site installation, and the measurement res...

Embodiment 2

[0036] Embodiment two, according to the attached figure 1 Shown, a kind of measuring method using above-mentioned volumetric gas-liquid two-phase flowmeter comprises the following steps:

[0037] In the first step, the first pressure transmitter 1 measures the pressure P of the gas flowing through the metering pipeline for a period of metering time 1 ;

[0038] In the second step, the first positive displacement flowmeter 2 measures the volume C of the gas-liquid two-phase mixed fluid flowing through the metering pipeline for a period of metering time 1 ;

[0039] In the third step, the second pressure transmitter 4 measures the pressure P of the gas flowing through the differential pressure tube within a certain period of time in the measured metering pipeline. 2 ;

[0040] In the fourth step, the second positive displacement flowmeter 5 measures the volume C of the gas-liquid two-phase mixed fluid flowing through the differential pressure tube within a certain period of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com