Bone conduction sound production device and wearable equipment

A sound device and bone conduction technology, applied in the field of wearable devices and bone conduction sound devices, can solve the problems of low sound quality, lack of bass part of the sound, strong vibration, etc., to improve product sound quality, improve user experience, and improve The effect of acoustics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

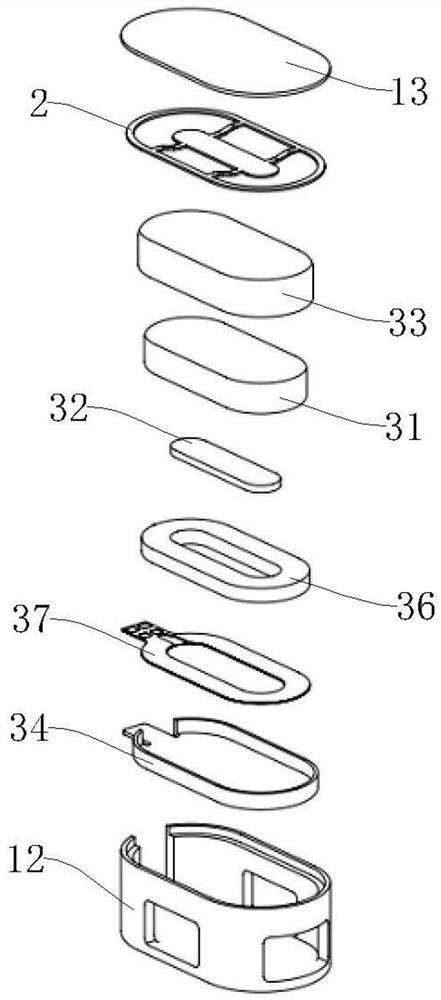

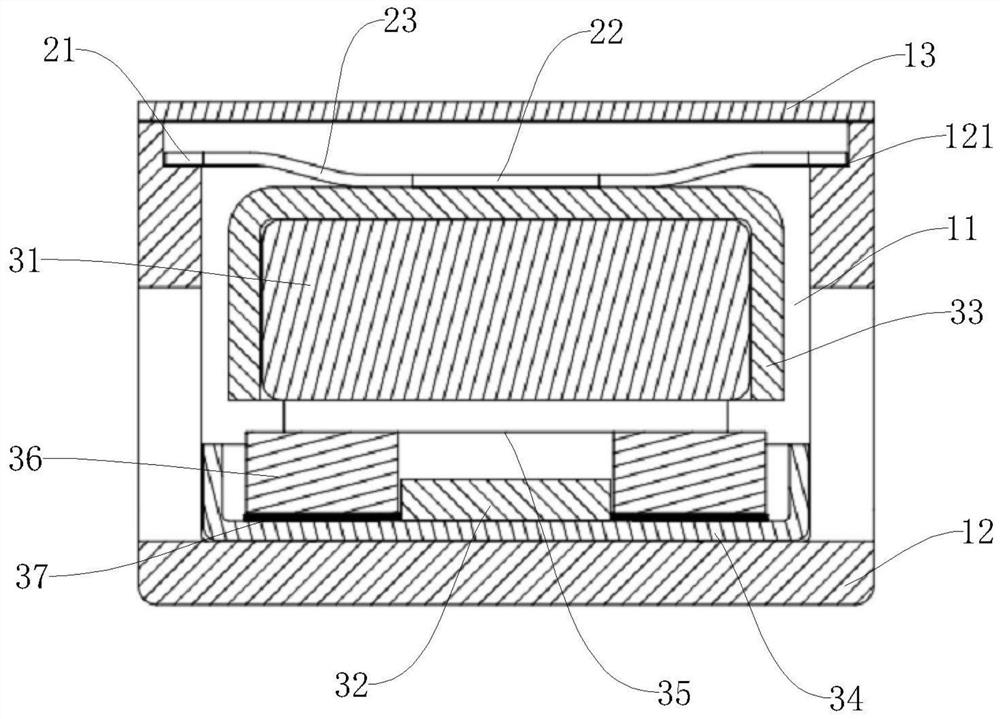

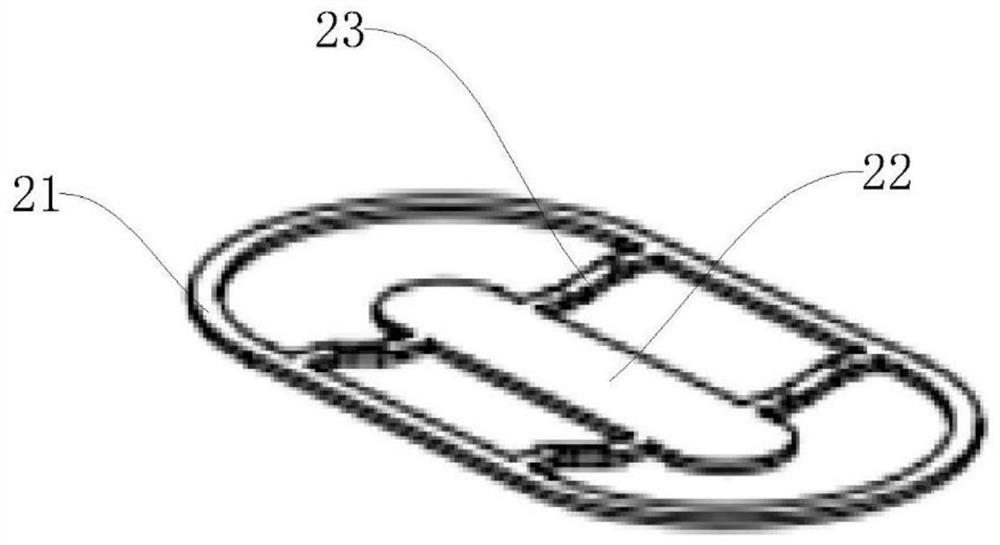

[0052] like Figures 1 to 3 As shown, in order to make the hollow elastic piece 2 not whole attached to the upper magnetic bowl 33, in this embodiment, the inner elastic piece 21 and the outer elastic piece 22 of the hollow elastic piece 2 are arranged at positions staggered from each other in the horizontal direction, and the outer elastic piece 22 Embedded in the outer packaging structure, the inner elastic sheet 21 is connected to the upper magnetic bowl 33 of the exciter. The inner elastic sheet 21 and the connecting elastic sheet 23 cooperate to adjust the effective vibration area of the hollow elastic sheet to adjust the resonance frequency of the device.

[0053] Specifically, in the present embodiment, the connecting elastic pieces 23 are arranged obliquely to achieve the purpose that the inner elastic pieces 21 and the outer elastic pieces 22 are arranged at positions staggered from each other in the horizontal direction. The lower end of 23 is connected to the inne...

Embodiment 2

[0057] like Figures 4 to 7 As shown, in order to make the hollow elastic piece 2 not whole attached to the upper magnetic bowl 33, in this embodiment, an upwardly protruding boss 332 is provided on the top wall 331 of the upper magnetic bowl 33, and the outer elastic piece 22 is embedded in the upper magnetic bowl 33. In the external packaging structure, the inner elastic sheet 21 is connected to the boss 332, and the inner elastic sheet 21, the connecting elastic sheet 23 and the boss 332 cooperate to adjust the effective vibration area of the hollow elastic sheet to adjust the resonance frequency point of the device;

[0058] Specifically, by setting the bosses 332 on the upper magnetic bowl 33 to connect the hollow elastic piece 2 and the exciter, so that the hollow elastic piece 2 is not attached to the upper magnetic bowl 33 as a whole, and the hollow elastic piece 2 and the exciter can be freely adjusted on the Z axis. The frame stacking in the direction can adjust th...

Embodiment 3

[0062] like Figures 7 to 9 As shown, in order to make the hollow shrapnel 2 not whole attached to the upper magnetic bowl 33, in this embodiment, the upper magnetic bowl 33 is preferably designed so that the bottom surface area of the upper magnetic bowl 33 is smaller than the bottom surface area of the upper magnetic member 31, The exciter is directly connected to the inner shrapnel 21 of the hollow shrapnel 2 through the upper magnetic bowl 33. The inner shrapnel 21, the connecting shrapnel 23 and the upper magnetic bowl 33 cooperate to adjust the effective vibration area of the hollow shrapnel 2 to adjust the resonance frequency of the device.

[0063] Specifically, the bottom surface of the upper magnetic bowl 33 is smaller than or equal to the surface area of the inner elastic piece 21. The upper magnetic bowl 33 adjusts the stacking of the hollow elastic piece and the exciter in the Z-axis direction, and adjusts the difference between the upper magnetic piece 31 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com