Crystallizing tank for crystallizing cannabidiol in industrial hemp

A technology for cannabidiol and industrial hemp, which is applied in the field of cannabidiol production and can solve the problems of inconvenient handling and use of devices, uneven crystallization of cannabidiol, uneven heating of devices, and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

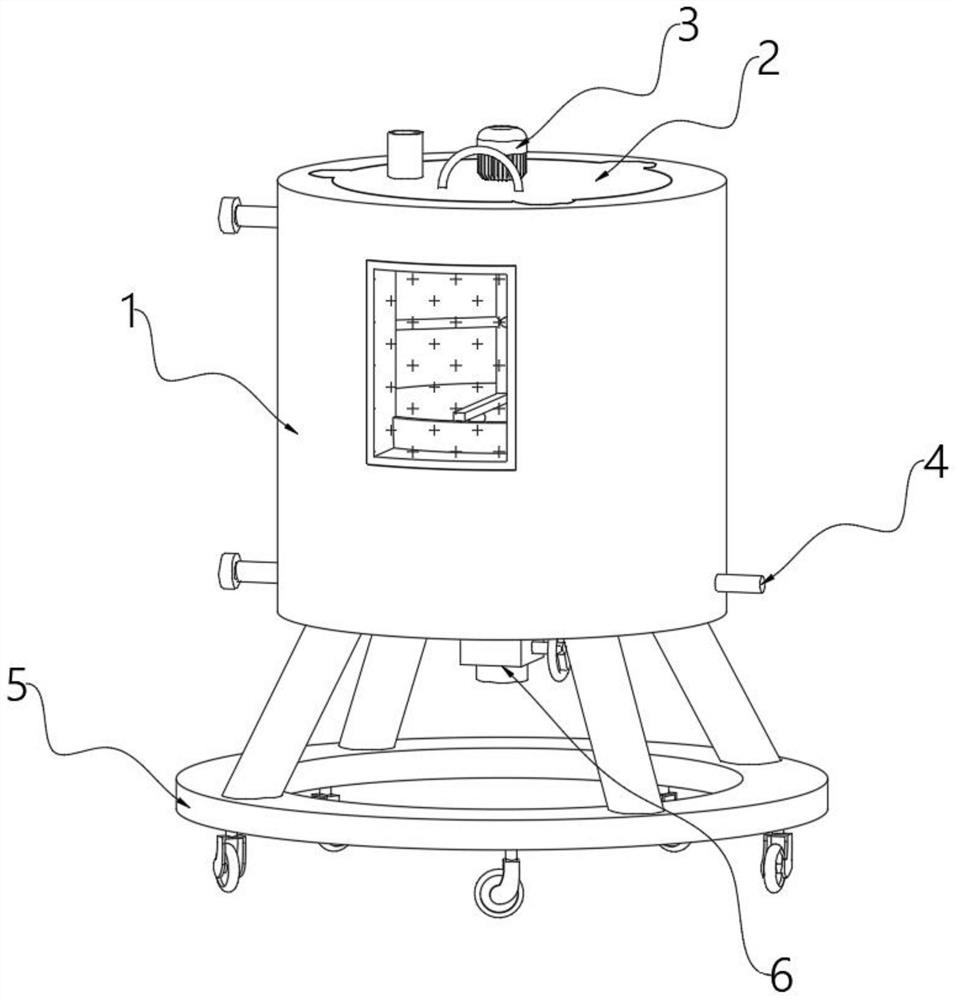

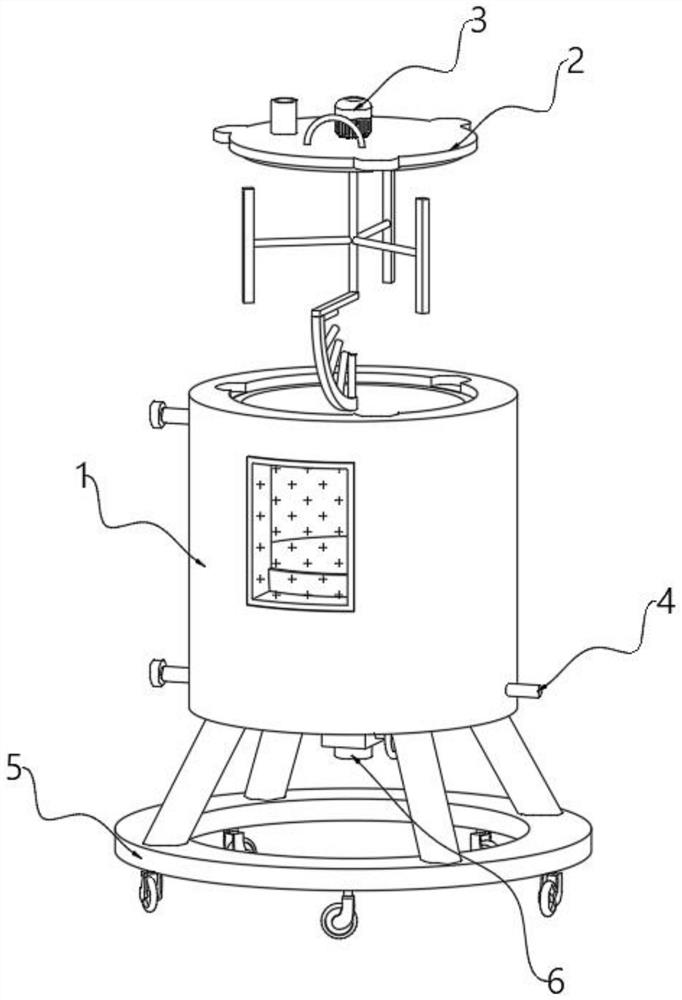

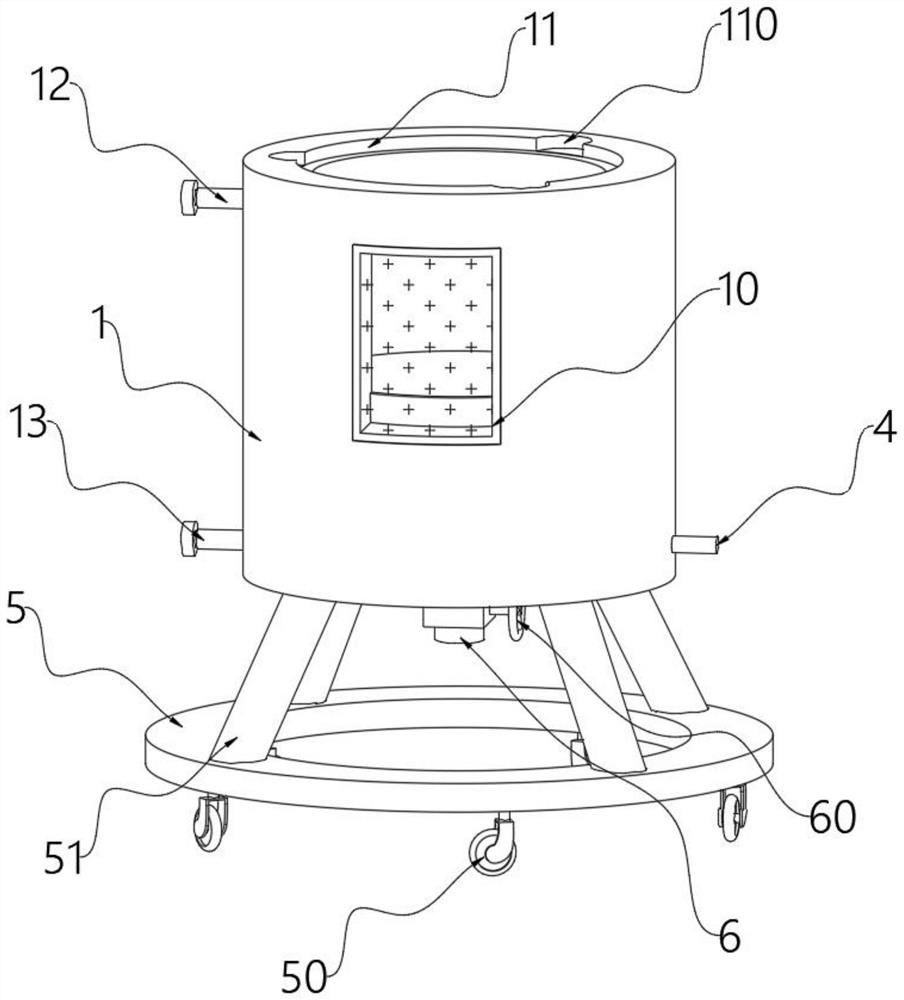

[0035] A crystallization tank for crystallizing cannabidiol in industrial hemp. A box cover 2 is provided, and a motor 3 is provided at the center of the upper surface of the box cover 2. The output shaft of the motor 3 passes through the box cover 2, and the output shaft is coaxially connected with a main shaft 30, and the bottom of the main shaft 30 is provided with an arc-shaped plate 33, crystallized The hollow area between the tank body 1 inner wall and the outer wall is a water bath layer 14, and a heating rod 4 is arranged in the water bath layer 14, and a water inlet pipe 12 communicated with the water bath layer 14 is embedded on the outer wall of the crystallization tank body 1 circumference near the top position. A water outlet pipe 13 communicating with the water bath layer 14 is embedded near the bottom position on the outer wall of the tank body 1 circumference, and a discharge pipe 6 communicating with the inside is embedded at the center of the bottom of the cry...

Embodiment 2

[0039] The difference with embodiment 1 is that the outer wall of the crystallization tank body 1 of the present embodiment is also embedded with an observation window 10 near the top, the observation window 10 is bonded and fixed with the crystallization tank body 1, and the observation window 10 is made of tempered glass Formed, high temperature resistance and can also pass through light, see the internal situation, observation window 10 is long and is 40cm, and width is 30cm, is convenient to watch the internal situation in real time.

Embodiment 3

[0041] The difference from Embodiments 1 and 2 is that the water inlet pipe 12 of this embodiment is welded and fixed with the crystallization tank body 1, and the water outlet pipe 13 is welded and fixed with the crystallization tank body 1, and the ends of the water inlet pipe 12 and the water outlet pipe 13 are equipped with Sealing plug, water inlet pipe 12 is convenient to fill heating water source in water bath layer 14, and outlet pipe 13 is convenient when not in use, discharges water bath layer 14 and divides waste liquid, reduces overall weight, is convenient to carry and use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com