A color steel corrugated board positive pressure coating device and its application method

A film covering device and corrugated board technology, applied in lamination devices, chemical instruments and methods, lamination, etc., can solve the problems of inconvenient blow molding position and maintenance of cutting components, so as to improve film covering efficiency and reduce limitations , Accelerate the effect of cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

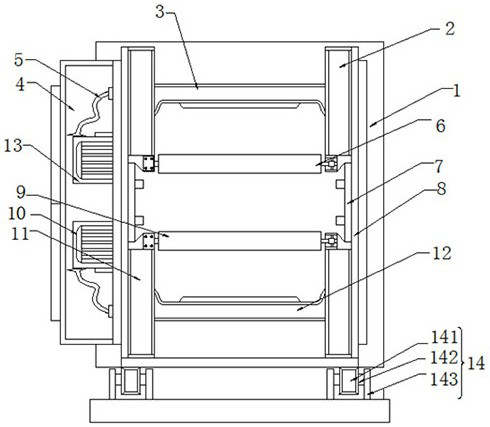

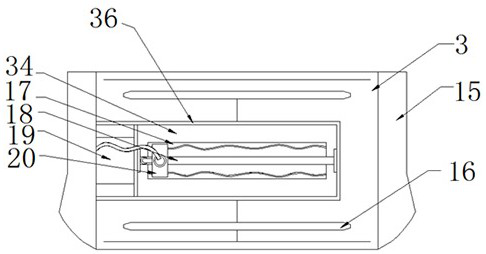

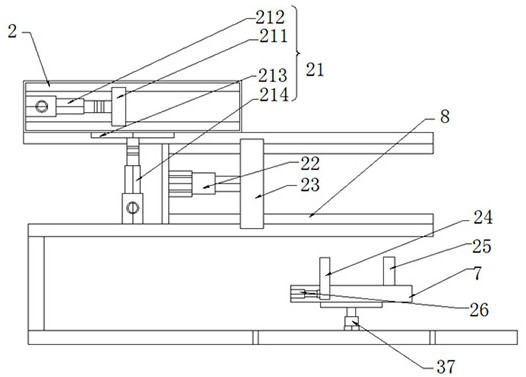

[0033] see Figure 1 to Figure 6, the present invention provides a technical solution: a color steel corrugated board positive pressure film coating device and its use method, including a connecting frame 1, an upper placing frame 2, an upper horizontal plate 3, an accommodating frame 4, a suction pipe 5, and an upper rolling film 6. Limiting plate 7, connecting plate 8, lower roll film 9, first servo motor 10, lower placing frame 11, lower horizontal plate 12, second servo motor 13, rotating assembly 14, connecting sleeve plate 141, rotating shaft 142, Fixed side plate 143, connecting block 15, scraper 16, heating chamber 17, connecting shaft 18, motor 19, suction fan 20, adjustment assembly 21, fixing plate 211, first hydraulic air rod 212, bottom plate 213, second hydraulic air Rod 214, third hydraulic air rod 22, connecting side plate 23, movable plate 24, fixed plate body 25, first electric push rod 26, auxiliary component 27, shaft body 271, connecting shaft 272, bushing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com