Intermittent quantitative blanking device and control method thereof

A blanking device and intermittent technology, which is applied to the intermittent quantitative blanking device and its control field, can solve the problems of inconsistent material density and fluidity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

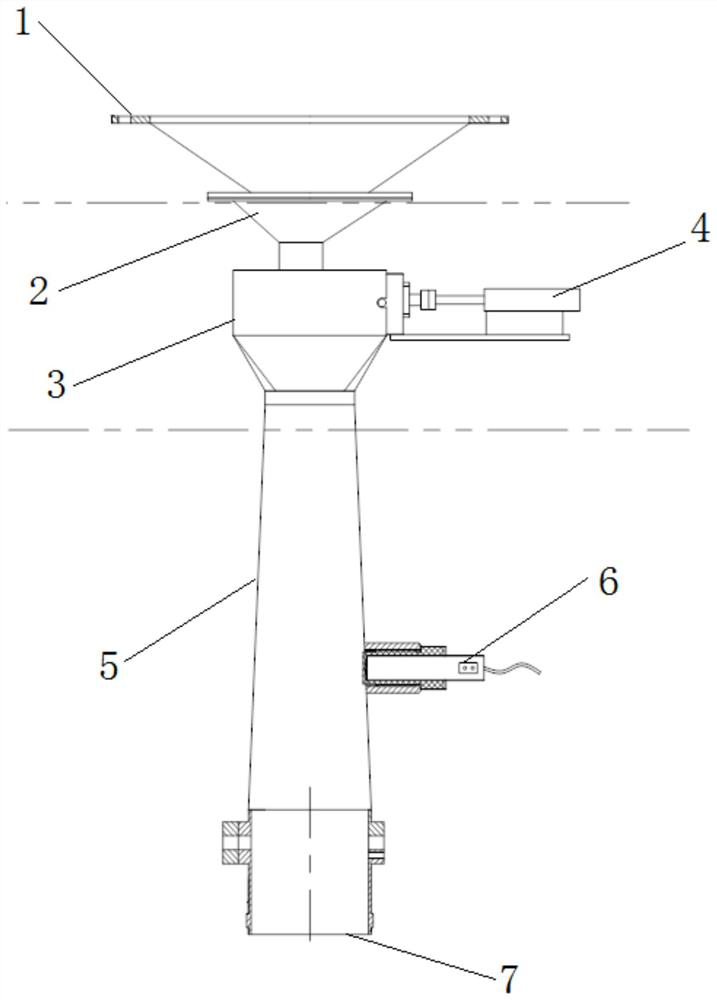

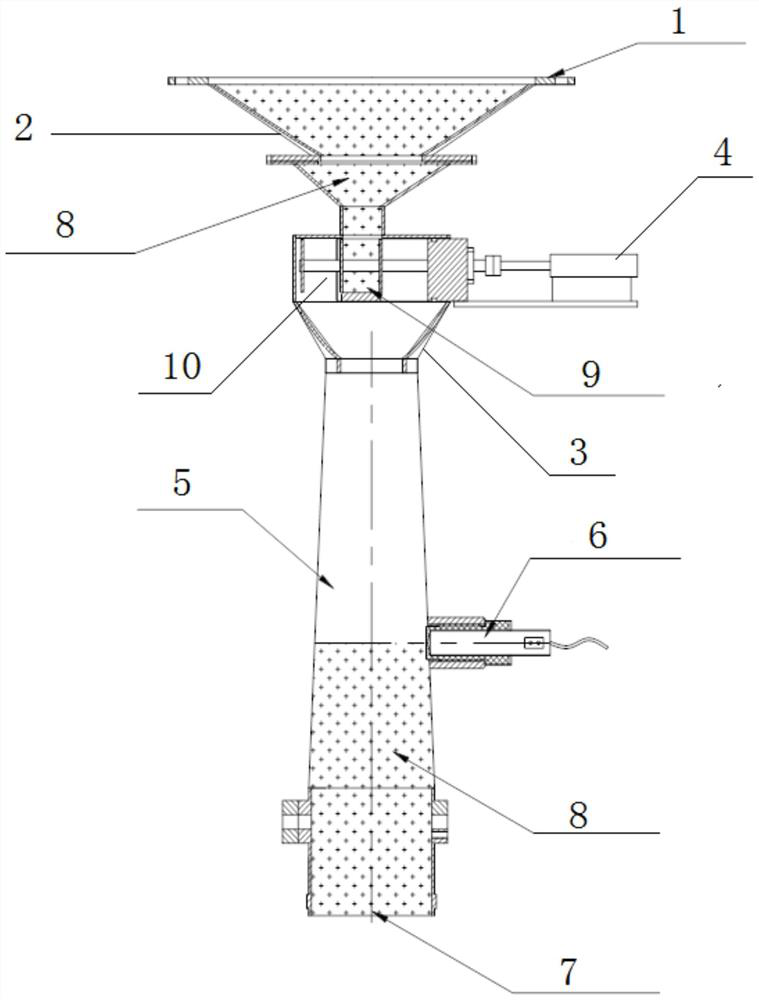

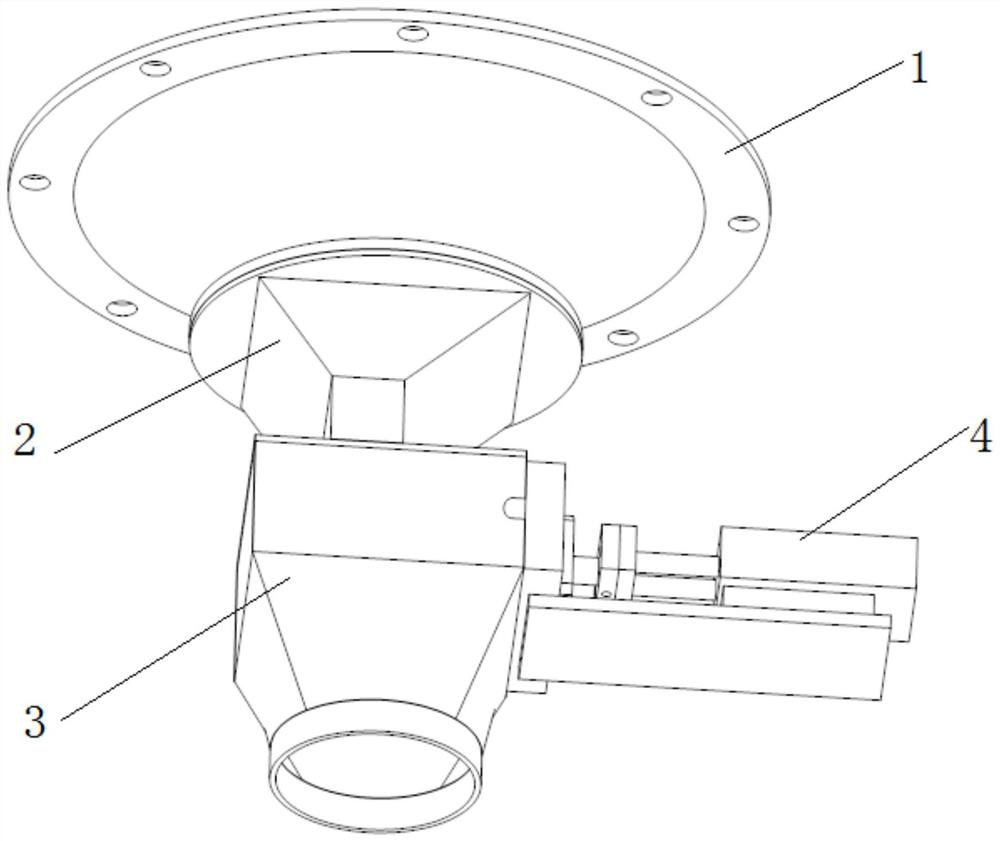

[0034] Such as figure 1 , 2 As shown, an intermittent quantitative blanking device includes a sheet metal silo module, a quantitative blanking control mechanism 4, and a blanking tube 5. The sheet metal silo module includes a transition cone storage bin 2 and is connected to a transition cone The blanking bin 3 at the lower part of the storage bin 2 is connected to one end of the quantitative blanking control mechanism 4 in the blanking bin 3, and the lower part of the blanking bin 3 is connected to the feeding pipe 5 through a docking piece 11, and a feeding pipe 5 is arranged outside the feeding pipe 5. The level sensor 6 , specifically the material level sensor 6 is arranged at the lower part of the feeding pipe 5 . Wherein, the upper part of the transitional conical storage bin 2 is connected to the feeding mechanism through the flange plate 1, and the lower end of the feeding pipe 5 is connected to the equipment feeder through the docking port 7. In the figure, componen...

Embodiment 2

[0043] The present invention also provides a control method of an intermittent quantitative blanking device, comprising:

[0044] When the material is lower than the position of the material level sensor 6, the PLC controller of the intelligent control module controls the solenoid valve to issue an action command, the solenoid valve opens, the double-axis cylinder 41 moves, and the cylinder drive shaft 42 drives the connecting shaft 46 to reciprocate to realize alternate filling, Blanking work, specifically:

[0045] When the cylinder transmission shaft 42 is stretching out, the second gap 48 between the two pusher plates 49 away from the connecting block 44 is separated from the blocking plate 43 to start the discharge work, and the two pusher plates 49 close to the connecting block 44 The first gap 47 and the blocking plate 43 form the quantitative storage bin 9 and start the filling work;

[0046] When the cylinder transmission shaft 42 is retracted, the first gap 47 betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com