Filament separating device, spinning equipment and polyacrylonitrile carbon fiber precursor

A technology of yarn separation and equipment, which is applied in the field of spinning technology, can solve the problems of doubling, broken yarn, sticking, large difference in the width of the original yarn, and poor bundling, so as to reduce breakage, reduce mutual entanglement, and reduce broken yarn and hairy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

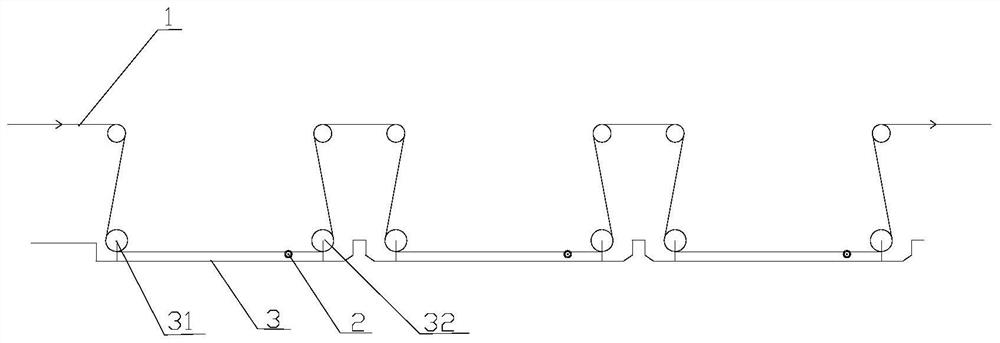

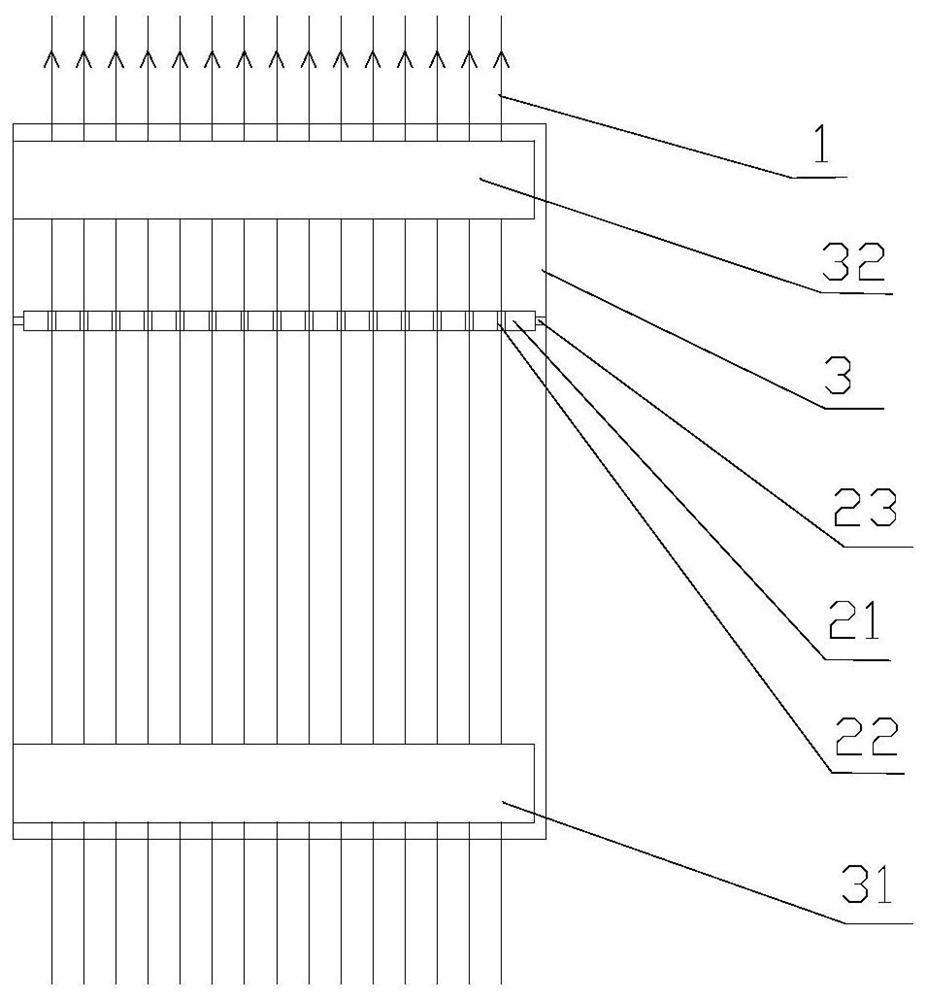

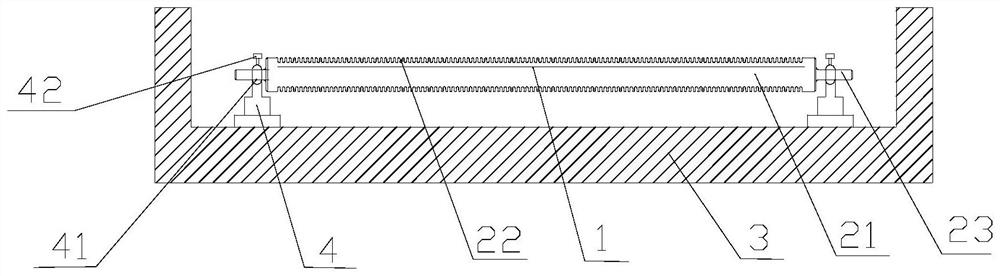

[0061] Such as Figure 1 to Figure 6 As shown, the present invention discloses a spinning device 2 and spinning equipment with the spinning device 2, which are used to produce and prepare polyacrylonitrile carbon fiber precursors. Specifically, the thread separating device 2 includes a thread separating rod 21 and a plurality of thread separating grooves 22 arranged axially at intervals on the peripheral sidewall of the thread separating rod 21 , and each thread separating groove 22 is arranged circumferentially. The wire separating groove 22 includes a notch 221 and a groove bottom 222 , and the width of the wire separating groove 22 decreases from the notch 221 to the groove bottom 222 .

[0062] In the present invention, the present invention makes the polyacrylonitrile carbon fiber precursor be constrained when the water washing tank 3 and the oiling tank run by setting the splitting groove 22, keeps the interval between the tows 1, reduces the mutual entanglement of the t...

Embodiment 2

[0066] In the present invention, the inner side wall 223 of the splitting groove 22 is arranged smoothly, and the tow 1 is in contact with the inner side wall 223 of the splitting groove 22, which is not easy to produce hairy filaments and broken filaments, and improves the performance of the tow 1.

[0067] As an implementation of this embodiment, the inner side wall 223 of the wire dividing groove 22 is smoothly connected with the groove bottom 222 of the wire dividing groove 22, so as to further improve the bundling performance of the wire dividing groove 22 on the tow 1, and Reduce broken filaments and fuzz in tow 1. At the same time, the relative concentration of stress at the junction of the inner wall 223 and the groove bottom 222 of the wire separating groove 22 is avoided, which will affect the strength of the tow 1 .

[0068] Further, the inner side wall 223 of the wire separating groove 22 is a smooth arc-shaped side wall;

[0069] Furthermore, the center of the ci...

Embodiment 3

[0071] In the present embodiment, the width of the dividing groove 22 is positively correlated with the number of monofilaments forming the tow 1 . Specifically, the greater the number of monofilaments forming the tow 1, the larger the width of the corresponding splitting groove 22, so that the tows 1 can all fall into the splitting groove 22, avoiding the occurrence of adhesion between adjacent tows 1 .

[0072] More specifically, the width of the notch 221 of the filament separating groove 22 is positively correlated with the number of monofilaments forming the tow 1 .

[0073] As an implementation of this embodiment, the number of monofilaments forming the tow is 1K-3K, and the width of the notch 221 of the wire dividing groove 22 is 6-12mm;

[0074] The number of monofilaments forming the tow is 6K-12K, and the width of the notch 221 of the wire dividing groove 22 is 10-18mm;

[0075] The number of monofilaments forming the tow is 24K-25K, and the width of the notch 221 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com