Afterburner structure based on self-excitation sweeping oscillation fuel nozzle

A technology of afterburner and fuel nozzle, applied in the direction of combustion chamber, continuous combustion chamber, combustion method, etc., can solve problems such as uneven distribution of fuel space, requirements for reducing the length of afterburner, difficult design goals, etc., to achieve Effects of improving combustion efficiency and combustion instability, shortening length, improving atomization performance and spatial distribution uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037]The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It can be understood that the specific implementation manners described here are only used to explain relevant content, rather than to limit the present invention. In addition, it should be noted that, for the convenience of description, only the parts related to the present invention are shown in the drawings.

[0038] It should be noted that, in the case of no conflict, the embodiments and features in the embodiments of the present invention can be combined with each other. The present invention will be described in detail below with reference to the drawings and in combination with embodiments.

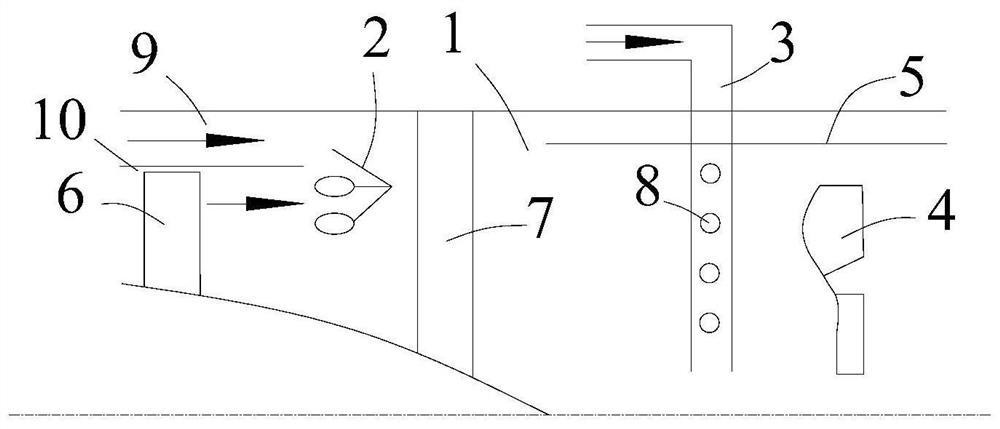

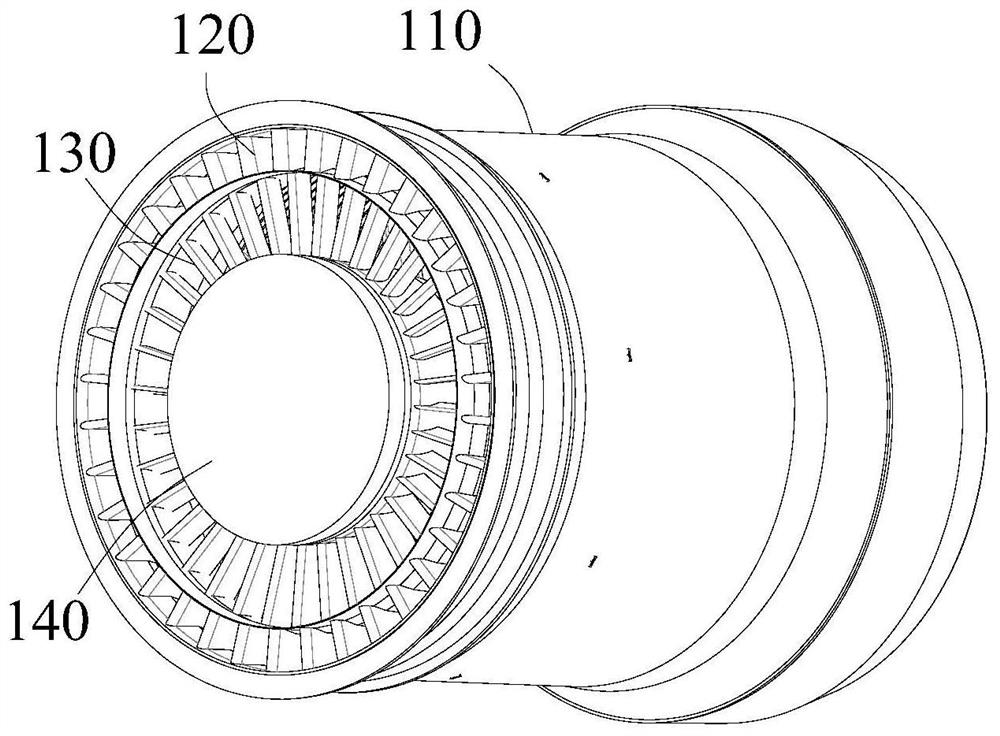

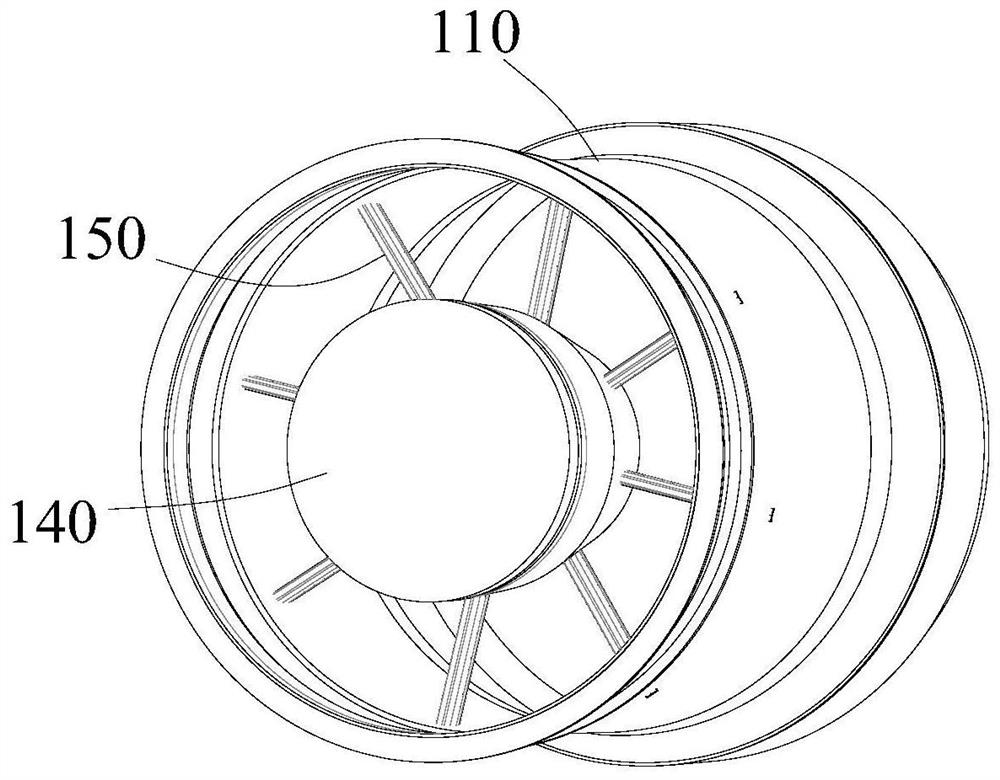

[0039] See attached figure 2 and attached Figure 4 , the present invention firstly discloses an afterburner structure based on a novel fuel nozzle 152 . The engine includes a casing 110 , an outer turbine 120 , an inner turbine 130 and a central...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com