Clamp for detecting friction corrosion of coating

A friction corrosion and fixture technology, used in weather resistance/light resistance/corrosion resistance, measuring device, testing wear resistance, etc. precision, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

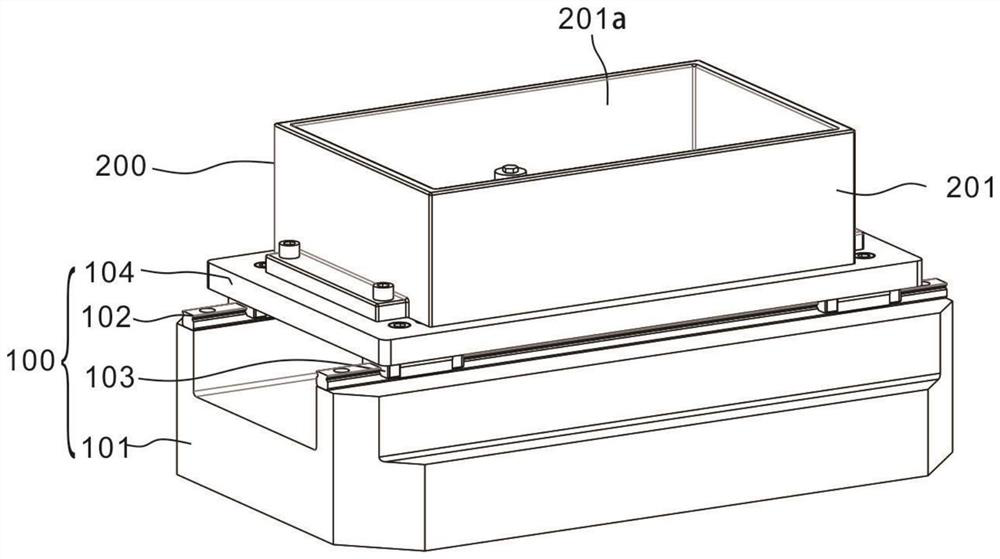

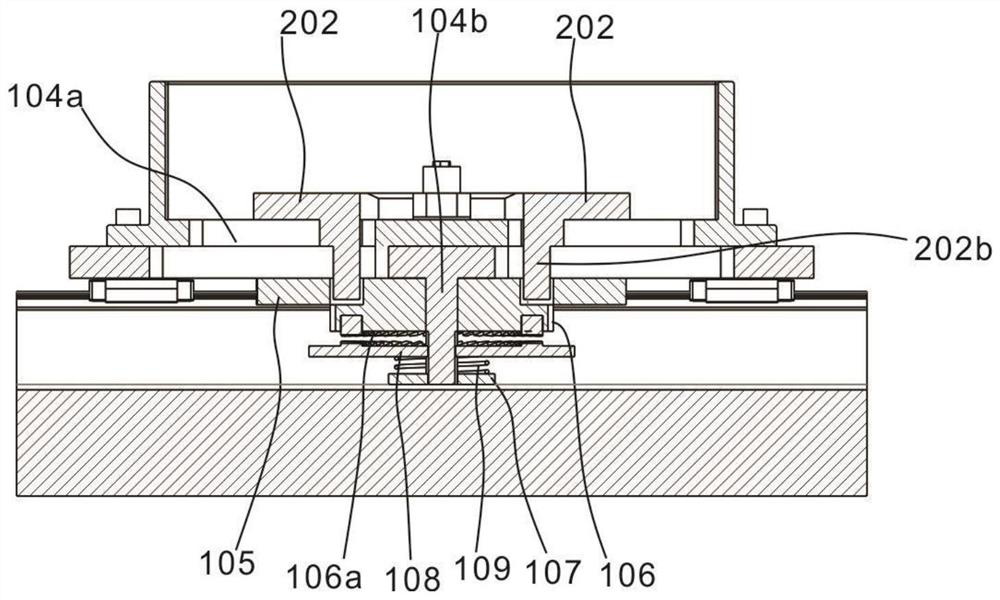

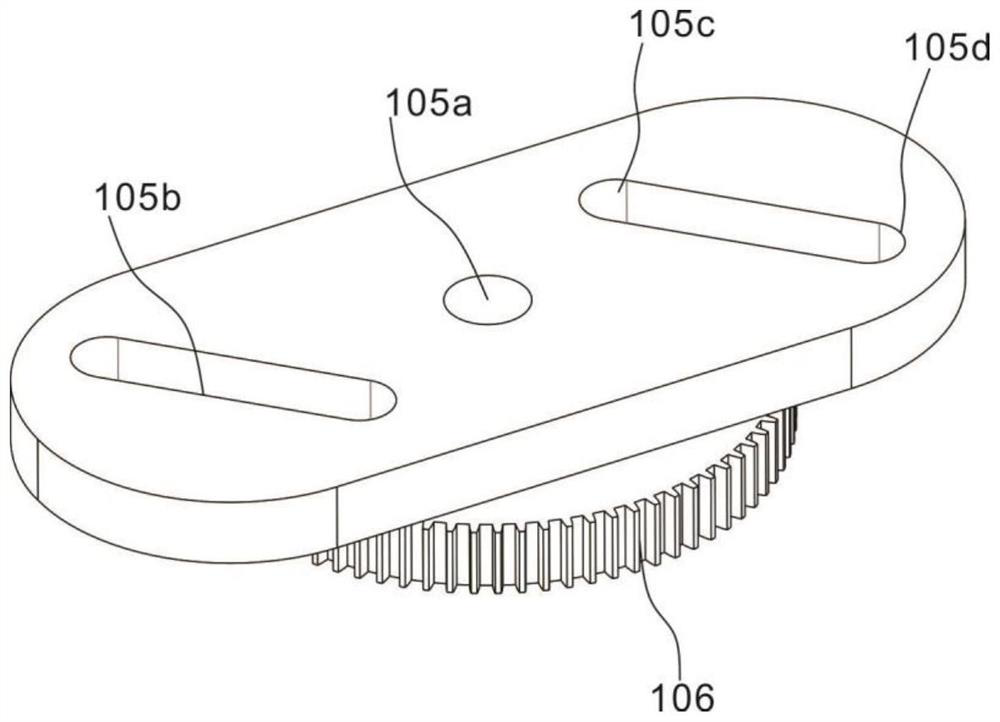

[0029] refer to Figure 1~5 , the present embodiment provides a fixture for coating friction and corrosion detection, including a support unit 100, a fixture unit 200, wherein the support unit 100 includes a fixture base 101, a sliding guide rail 102 installed on the fixture base 101, and a sliding The guide rail 102 cooperates with the chute 103 connected, and the chute 103 is installed below the base plate 104, wherein the sliding guide rail 102 is provided with two parallel ones, and the chute 103 is also provided with two, the chute 103 can move on the sliding guide rail 102, and also That is, the bottom plate 104 can move on the sliding guide rail 102 along the length direction of the sliding guide rail 102 .

[0030] Further, the clamp unit 200 includes a receiving part 201 fixedly installed on the bottom plate 104. The receiving part 201 is not a rectangular parallelepiped. One side of the receiving part 201 is recessed to form a clamping groove 201a. V-block 202 . Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com