Melt-blown nonwoven fabric for liquid filter, layered body of said melt-blown nonwoven fabric, and liquid filter equipped with layered body

A technology for melt-blown non-woven fabrics and liquid filters, which is applied in membrane filters, filtration separation, non-woven fabrics, etc. Good properties, high uniformity, fluffy surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

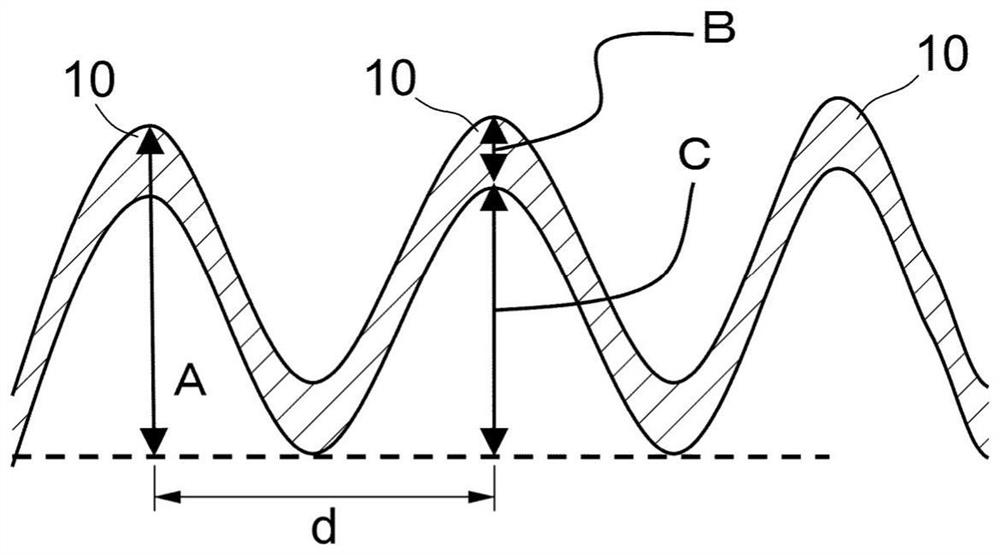

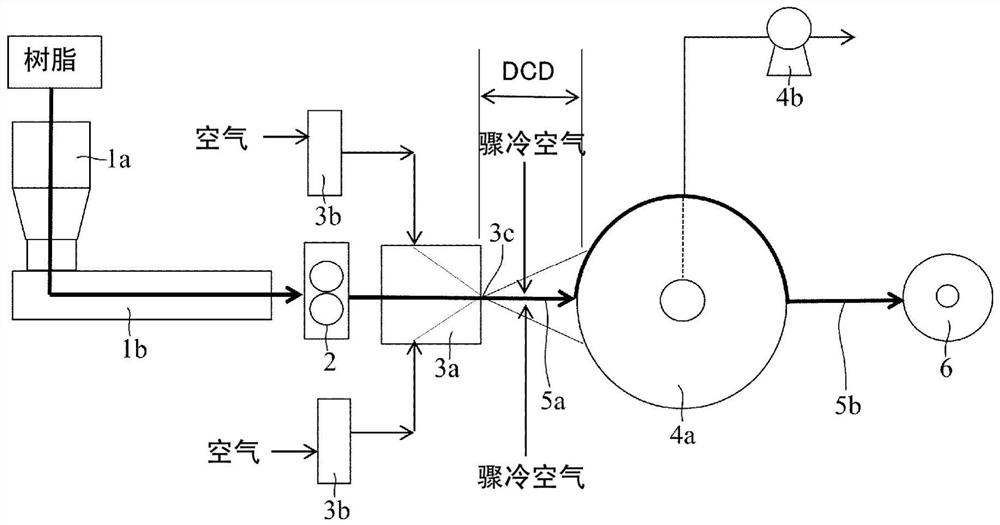

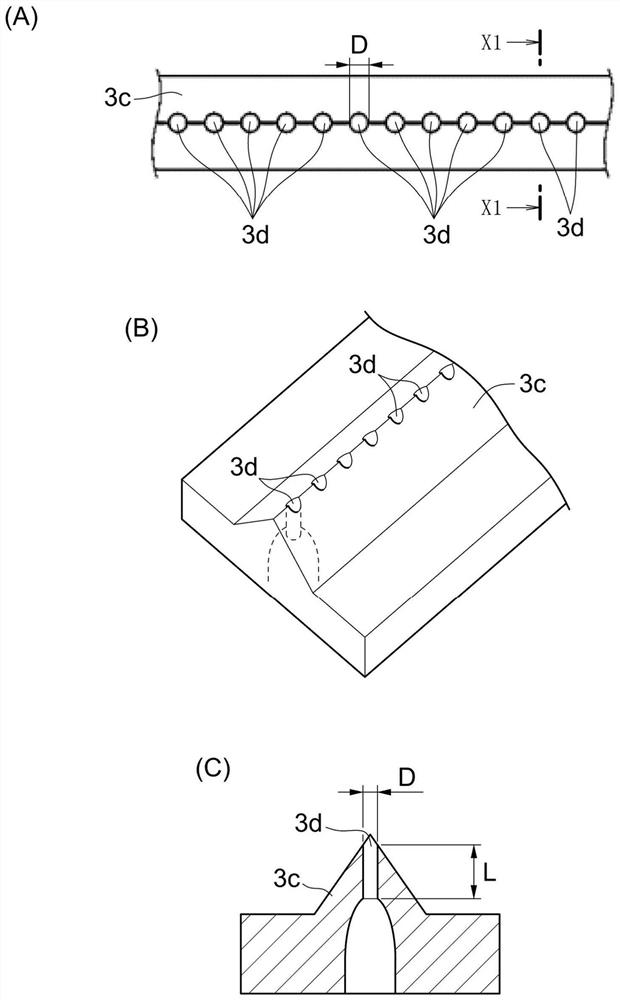

[0097] In the raw material hopper of the melt-blown manufacturing device, the homopolypropylene resin (weight-average molecular weight 1.7×10) that MFR is dropped into is 40 5 . The same applies to the following Examples and Comparative Examples), and the melt-kneading temperature was set to 330°C. With the distance between the die head and the collector 150mm, the resin and 290°C heated compressed air 25Nm 3 / min together from the nozzle to the atmosphere, contact with 20 ° C quench air for cooling 17m 3 / min later, at a suction volume of 60m 3 Fibrous resin is continuously collected on the collector at a rate of 1 / min, and the rotation speed of the collector is properly adjusted to obtain an average fiber diameter of 21.0 μm and an average weight per unit area of 45 g / m 2 , The maximum height A of the protrusion is 2.02 mm, the thickness B of the non-woven fabric is 0.09 mm, the thickness ratio A / B is 22.4, and the melt-blown non-woven fabric has a formation index of 32...

Embodiment 2

[0099] A homopolymer polypropylene resin with an MFR of 40 was charged into a raw material hopper of a melt-blown manufacturing device, and the melt-kneading temperature was set at 390°C. With the distance between the die head and the collector 200mm, the resin and 290°C heated compressed air 25Nm 3 / min together from the nozzle to the atmosphere, contact with the quenching air of 20 ℃ for cooling 17m 3 / min later, at a suction volume of 60m 3 The fibrous resin is continuously collected on the collector at a rate of 1 / min, and the rotation speed of the collector is properly adjusted to obtain an average fiber diameter of 33.6 μm and an average weight per unit area of 45 g / m 2 , The maximum height A of the protruding part is 2.10mm, the thickness B of the nonwoven fabric is 0.09mm, the thickness ratio A / B is 23.3, and the melt blown nonwoven fabric is 370. Regarding compression resistance, the thickness ratio A' / A was 0.85, and the air permeability ratio T' / T was 0.99.

Embodiment 3

[0101] A homopolypropylene resin with an MFR of 40 was charged into a raw material hopper of a melt-blown manufacturing device, and the melt-kneading temperature was set to 330°C. With the distance between the die head and the collector 200mm, the resin and 290°C heated compressed air 25Nm 3 / min together from the nozzle to the atmosphere, contact with the quenching air of 20 ℃ for cooling 17m 3 / min later, at a suction volume of 60m 3 Fibrous resin is continuously collected on the collector at a rate of 1 / min, and the speed of the collector is properly adjusted to obtain an average fiber diameter of 22.6 μm and an average weight per unit area of 45 g / m 2 , The maximum height A of the protruding part is 2.09mm, the thickness B of the nonwoven fabric is 0.12mm, the thickness ratio A / B is 17.4, and the melt blown nonwoven fabric is 350. Regarding the compression resistance, the thickness ratio A' / A was 0.86, and the air permeability ratio T' / T was 0.99.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com