An automatic discharge machine for capacitor production

A technology of capacitors and discharge machines, which is applied in the direction of conveyor objects, transportation and packaging, packaging, etc., can solve the problems of affecting the discharge effect, low work efficiency, misplaced arrangement, etc., and achieve coherent and tight coordination of discharge operations, and improve Work efficiency, ensure the effect of orderly arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

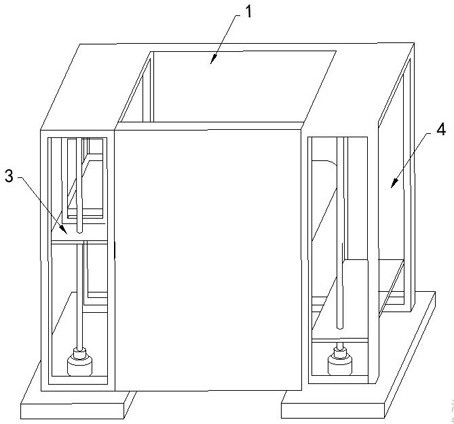

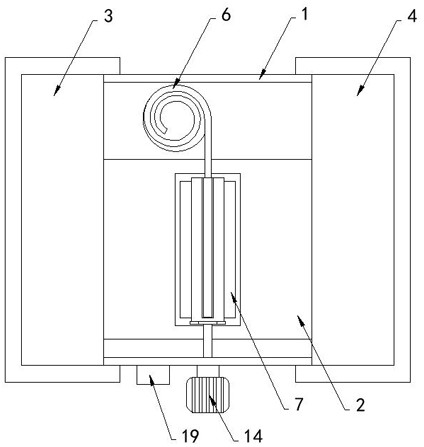

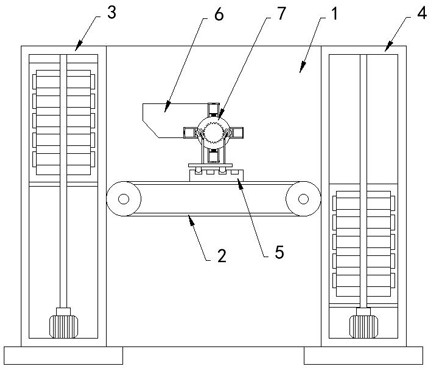

[0030] like Figure 1-7 As shown, a capacitor is produced with an automatic discharge machine, including a rack 1, a rack 1, a trace 2, a material disc supply mechanism 3, and a material discharge mechanism 4, and the transfer rail 2 can be a belt conveyor. The material disc supply mechanism 3 and the material disc dielectric 4 are all prior art, and there is no repertiction to the material disc supply mechanism 3, and the rack 1 is attached to the rack 6, the vibration disk 6 is attached. The output is provided with a discharge mechanism 7 for discharging the capacitor.

[0031] Specifically, the discharge mechanism 7 includes a rotating roller 8 and a plurality of side panels 9 fixed to the rotating roller 8, and several side plates 9 are arranged in parallel, and each set of side panels 9 and the circumference of the rotating roller 8 The tank 10 performed perpendicular to the transfer direction is formed, in the present embodiment, the side panel 9 has eight pieces, and the fou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com