Intelligent food storage and transportation sampling inspection equipment

A testing equipment and sampling testing technology, applied in the direction of transportation and packaging, loading/unloading, conveyor objects, etc., can solve the problems of inability to complete transportation and sampling synchronously, interfere with food transportation efficiency, green food pollution, etc. Repeated operation, fast sampling process, and enhanced stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

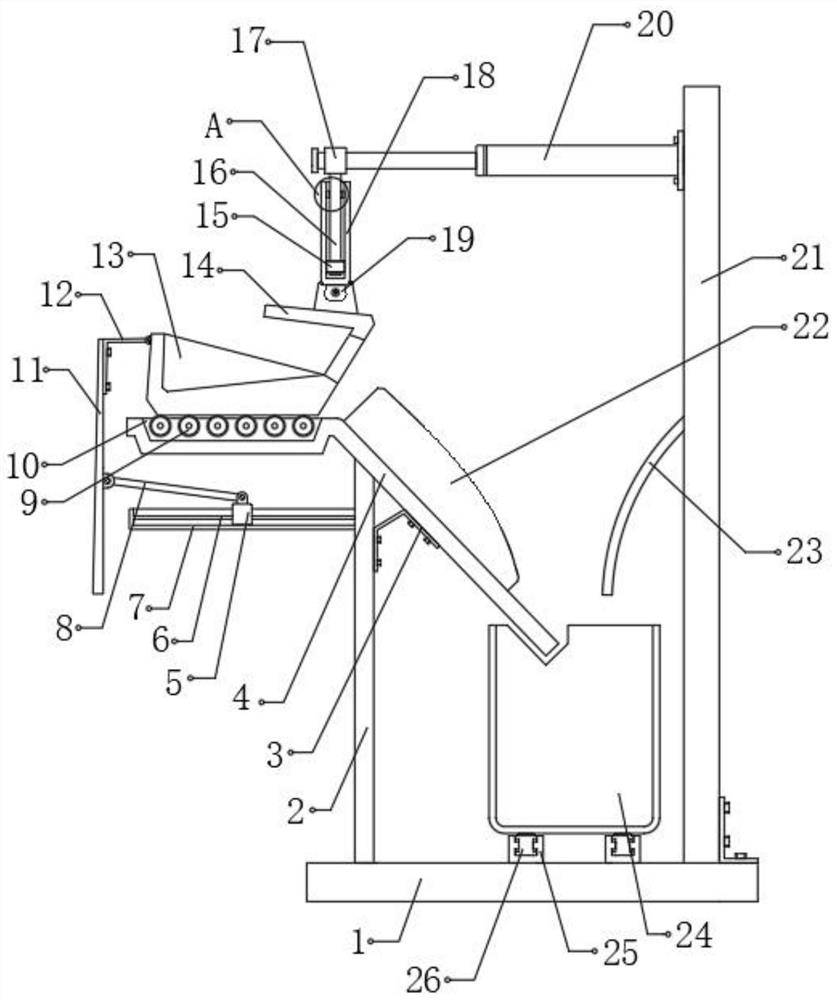

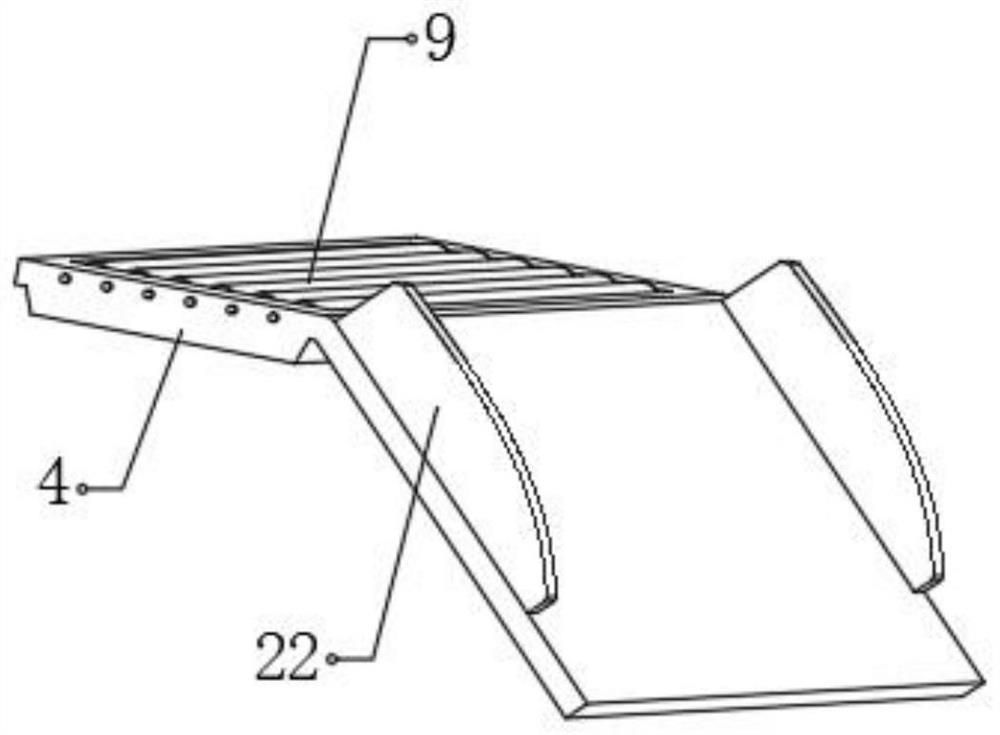

[0034] refer to Figure 1-5 , a food intelligent storage and transportation sampling inspection equipment, comprising a base 1 and a side plate 21, the side plate 21 is fixedly connected to one side of the top of the base 1, and the top of the base 1 away from the side plate 21 is fixedly connected to a support column 2, and The top of the support column 2 is fixedly connected with a blanking plate 4, the side of the blanking plate 4 near the side plate 21 is set as a slope, and the other side of the blanking plate 4 is set as a platform, and the side plate 21 is close to the blanking plate 4- The top of the side is fixedly connected with a push rod motor 20, and the end of the push rod motor 20 away from the side plate 21 is sleeved with a fixed ring 17, and the outer wall of the bottom of the fixed ring 17 is fixedly connected with a piston rod 16, and the bottom of the piston rod 16 is sleeved Limiting cylinder 18, the bottom of limiting cylinder 18 is rotatably connected w...

Embodiment 2

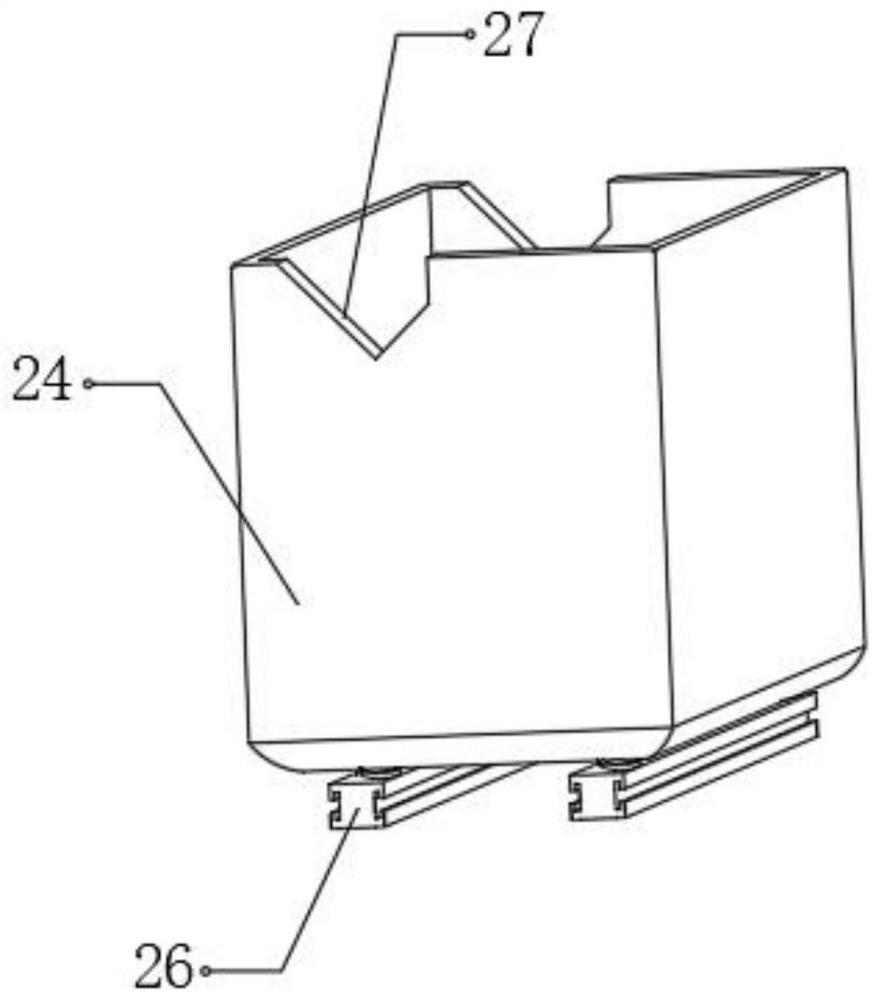

[0042] refer to Figure 6 , a kind of food intelligent storage and transportation sampling inspection equipment. Compared with Embodiment 1, this embodiment has a storage box 31 fixedly connected to the middle position of the bottom of the sample box 24, and a spring 36 is fixedly connected to the inner wall of the top of the storage box 31, and the spring 36 The bottom of the base 1 is fixedly connected with an L-shaped bolt 32, and the inner wall of the top of the L-shaped bolt 32 is fixedly connected with a positioning block 33, and the positioning block 33 is made of steel material, and the top of the base 1 is fixedly connected with an electromagnet 34, and the electromagnet 34 is located at the positioning block 33 Directly below, the top of the base 1 is provided with a positioning groove 35, and the bottom end of the L-shaped bolt 32 is located directly above the positioning groove 35.

[0043] After the electromagnet 34 is energized, the positioning block 33 is adsorb...

Embodiment 3

[0045] refer to Figure 1-5 , a food intelligent storage and transportation sampling inspection method, comprising a baffle plate 23, a push rod motor 20, a piston rod 16, a limit cylinder 18, a moving block 14, a sampling tank 13, a discharge port 29, a blanking plate 4 and a sample box 24. The base 1 is fixed on one side of the food conveyor belt, and the food continues to fall from one end of the conveyor belt. The push rod motor 20 pushes the moving block 14 out, and the food falls into the sampling tank 13, and then the push rod motor 20 pulls the moving block 14 back. The moving block 14 slides to the slope part from the platform part of the blanking plate 4, and the moving block 14 is converted into an inclined state from a horizontal state, and the food sample slides out from the sampling groove 13, and falls into the sample case 24. , the limiting cylinder 18 rotates relative to the moving block 14, the limiting cylinder 18 slides down along the piston rod 16, the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com