Crane Hoisting Intelligent Braking Device

A brake device and crane technology, which is applied in the direction of lifting equipment brake devices, hoisting devices, safety devices, etc., can solve the problems of lack of hoisting brake solutions, falling objects, etc., to avoid uncontrolled falling of materials and improve practicability , moving smoothly and smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

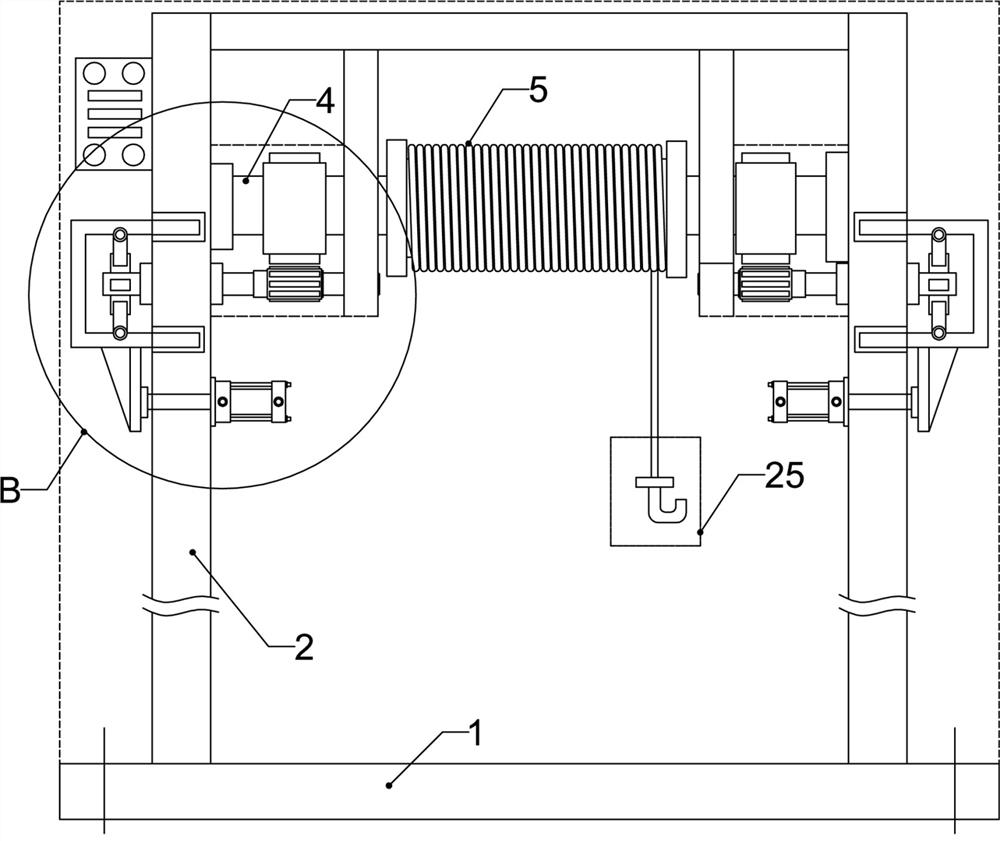

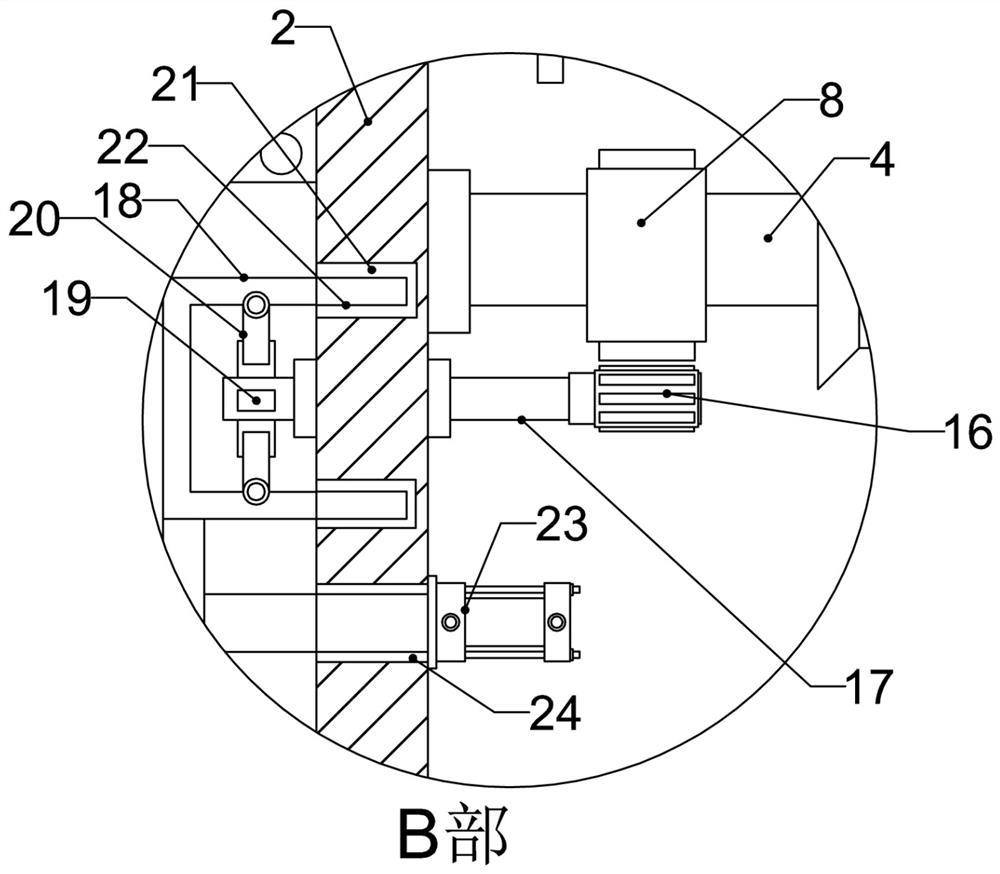

[0039] Embodiment 1: a kind of as figure 1 The crane hoisting intelligent braking device shown not only includes components such as the crane hanger, sling mechanism, and control cabinet, but also includes a set of mechanisms for effectively braking the carrying rod.

[0040] Specifically, such as figure 1 Among them, the hanger includes a lower base plate and an upper base plate and at least one pair of bearing walls. Between a pair of bearing walls of the crane hanger, a bearing roller is installed through a bearing assembly, and one end of the bearing roller is transmission-connected to a hoisting driving mechanism (not shown in the figure). The sling mechanism installed on the carrying roller includes a hoist, a sling and a hook mechanism, etc., and the sling mechanism can be realized in any form of existing hoisting equipment. At the same time, the bearing roller is connected with the reverse self-locking mechanism through the transmission mechanism. figure 1 It can be...

Embodiment 2

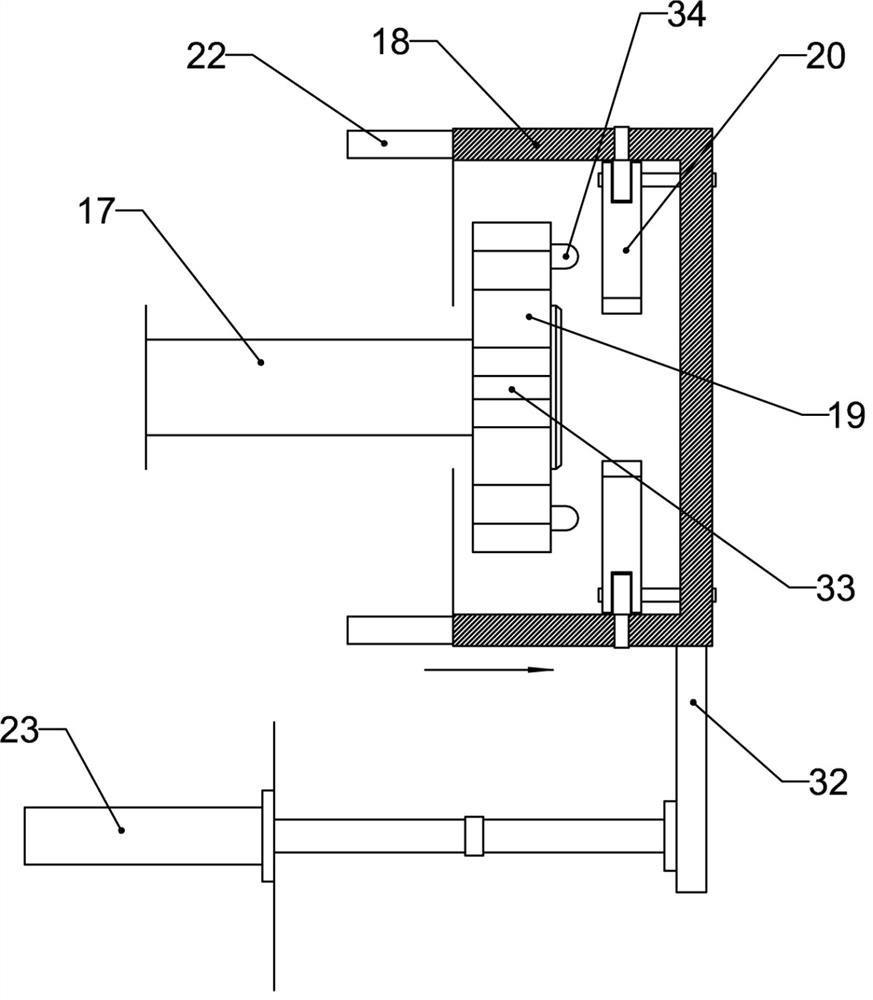

[0050] Embodiment 2: On the basis of Embodiment 1, the similarities will not be repeated. The difference is that the structure of the cylindrical frame of the reverse self-locking mechanism and the structure of the linear drive mechanism are changed.

[0051] Specifically, the cylindrical frame is designed as a fixed frame, which is fixed on the outside of the load-bearing wall. Such as Figure 9 As shown, the transmission rod designed with the reverse self-locking mechanism includes a spline shaft and a spline sleeve, which can translate axially and rotate synchronously after being fitted.

[0052] The spline shaft is located at the outer end or the spline sleeve is located at the outer end, and the cam wheel is sleeved on the spline sleeve located at the outer end or is sleeved on the spline shaft. At the same time, there is also a shift fork that drives the spline sleeve or the spline shaft to move axially, such as Figure 9 Among them, the shift fork is set on the outsid...

Embodiment 3

[0056] Embodiment 3: On the basis of Embodiment 1 or 2, the engagement relationship between the convex plate and the limiting plate is designed.

[0057] Specifically, outwardly protruding guide rods are respectively provided on one side of each protruding plate, and the ends of each lead-out rod are fixed as a whole by a support ring, there is a gap between adjacent guide rods, and each limiting plate is inserted into the corresponding gap Inside, each guide rod can move each limit plate clockwise or counterclockwise, and still maintain a clockwise or counterclockwise dumping state after the load roller stops rotating, so that the load roll can pass through the limit plate after it stops rotating. into the gaps between the convex plates.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com