Construction method for integrally pouring prestressed pipe pile with conjoined pile cap

A technology of prestressed pipe piles and construction methods, applied in construction, sheet pile walls, foundation structure engineering, etc., can solve the problems of reducing the construction difficulty of pipeline stability, and achieve the goals of protecting the construction environment, reducing the difficulty of sealing, and improving quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

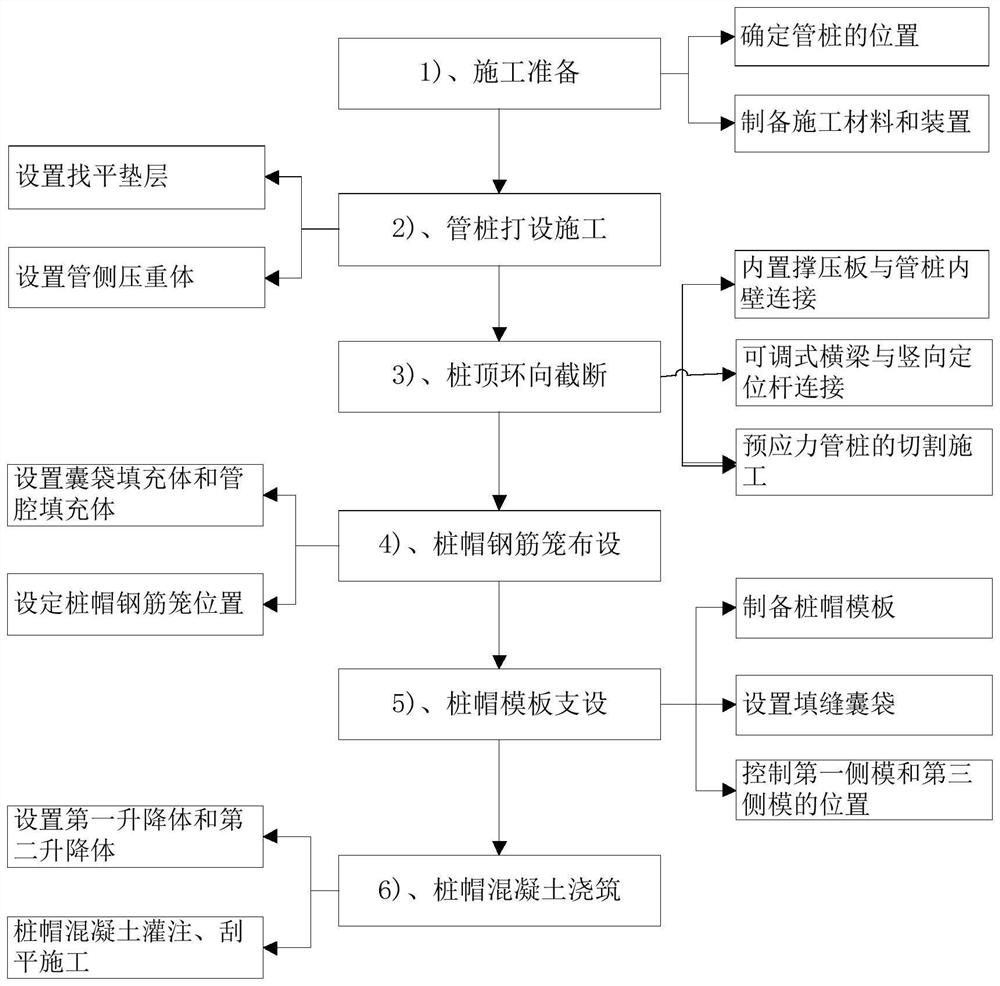

[0038] figure 1 It is the construction flow chart of integrated pouring pipe pile with connected pile cap of the present invention, referring to figure 1 As shown, the construction method of integrally pouring prestressed pipe piles with conjoined pile caps includes the following construction steps:

[0039] 1) Construction preparation: carry out on-site testing to determine the plane position of the prestressed pipe pile 9, and prepare materials and devices required for construction;

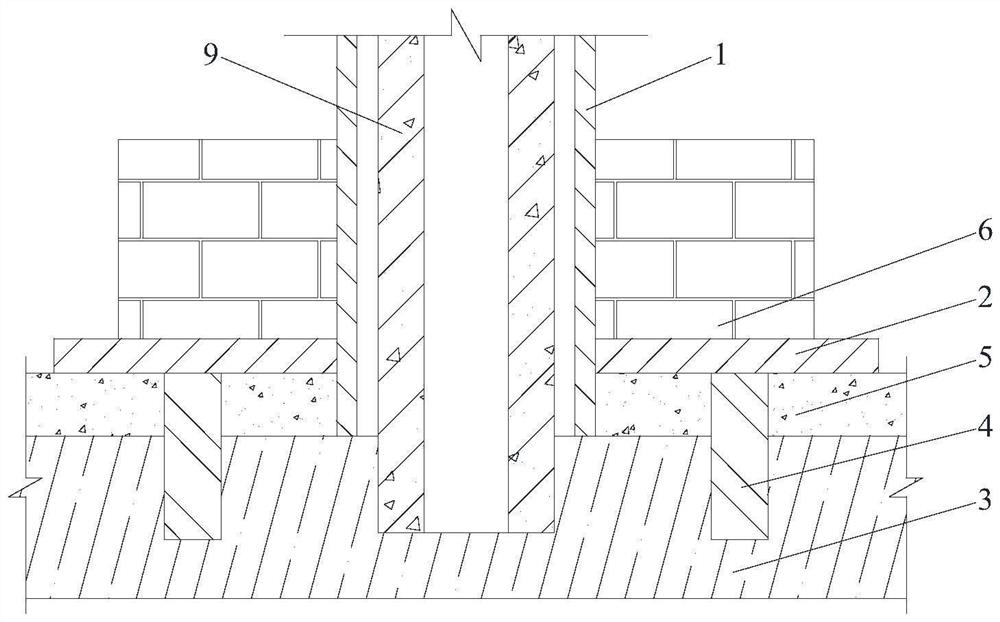

[0040] 2) Construction of pipe piles: According to the surveyed position of prestressed pipe piles 9, place the integrated guide sleeve 1 and pipe side support plate 2 above the soil 3 between the piles, and insert the support plate anchor bar 4 into the pile In the soil body 3 between the piles, a leveling cushion 5 is set in the gap between the pipe side brace 2 and the pile soil 3; the pipe side pressure weight 6 is set on the upper surface of the pipe side brace 2; external piling equipmen...

Embodiment 2

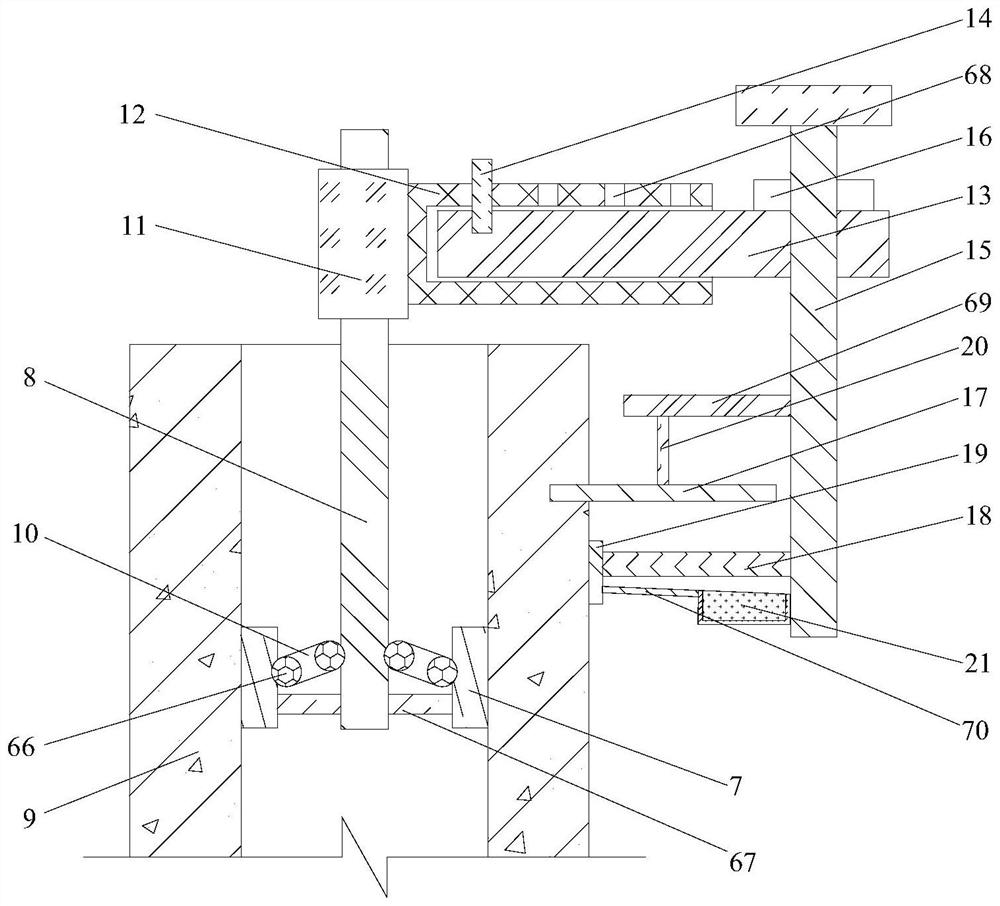

[0046] figure 2 is a schematic diagram of the layout of the guide casing, image 3 It is a schematic diagram of the vertical section of the prestressed pipe pile cutting device, Figure 4 It is the plane schematic diagram of the prestressed pipe pile cutting device, Figure 5 is a schematic diagram of the cross-sectional structure of the flexible connection section, Image 6 It is a schematic diagram of the pile cap reinforcement cage arrangement structure, Figure 7 is a schematic diagram of the pile cap steel cage support fixed structure, Figure 8 is the top view of the pile cap formwork support structure, Figure 9 is the elevation view of the pile cap formwork support structure, Figure 10 is a schematic diagram of the pile cap concrete pouring and scraping structure, Figure 11 It is a structural schematic diagram of the first squeegee body (second squeegee body). refer to Figure 2 to Figure 11 As shown in the figure, the prestressed pipe pile is poured integra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com