Multi-way valve device

A multi-way valve and spool technology, applied in the direction of valve device, multi-way valve, valve operation/release device, etc., can solve the problem of increasing connecting pipelines and control harnesses, high cost of valve components, few valve function modes, etc. Problems, to achieve the effect of compact layout, reduce water inlet or outlet flow resistance, and improve sealing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

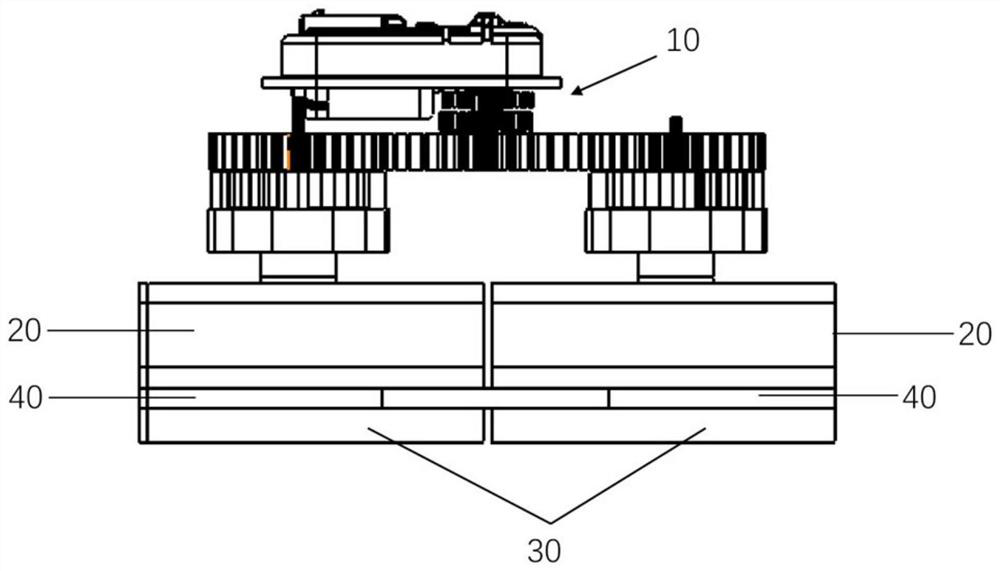

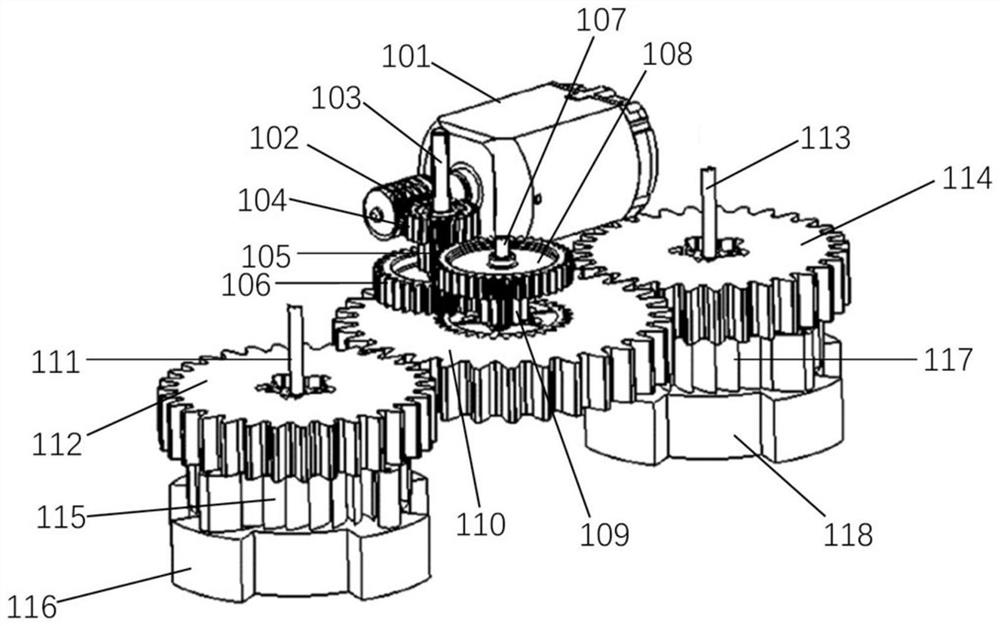

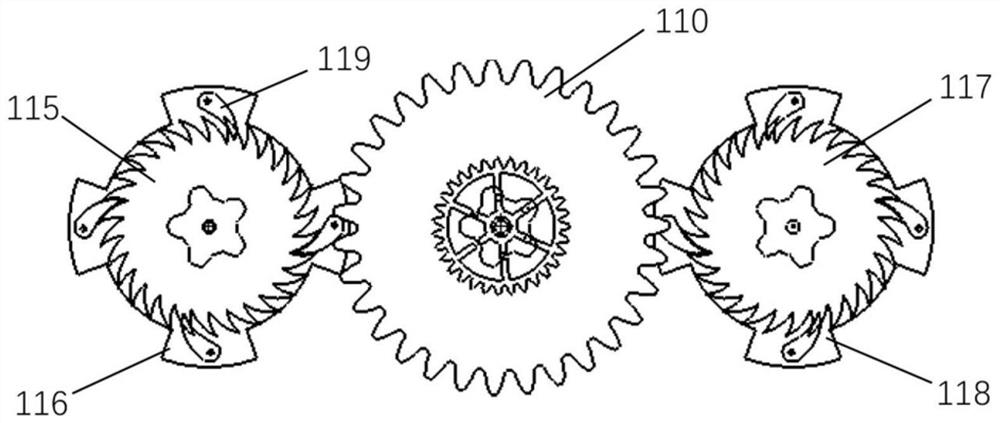

[0037] figure 1 is a structural schematic diagram of a multi-way valve device according to an embodiment of the present invention. Such as figure 1 As shown, in one embodiment, the multi-way valve device includes a power driver 10 , a plurality of spools 20 and a plurality of end plates 30 . Each spool 20 is driven to rotate by the power drive device 10 , and each spool 20 is provided with multiple groups of connected spool ports. Each end plate 30 covers each valve core 20, and each end plate 30 is provided with a plurality of interfaces for connecting the valve core port and the outside, and each interface is located on at least one valve core of its corresponding valve core 20 On the movement trajectory of the port, each valve core 20 is connected to the corresponding target interface at the end plate 30 when each valve core 20 rotates to each target angle. Here, the spool 20 may adopt a composite structure of a butterfly valve and a ball valve.

[0038] The multi-way v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com