Light beam alignment device and alignment method for ultralow-temperature vacuum environment

A technology for aligning devices and vacuum environments, applied in measuring devices, photometry, optical radiation measurement, etc., can solve the problems of difficult alignment and debugging, low precision, etc., and achieve simple structure, high beam alignment accuracy, and applicable The effect of wide wavelength range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

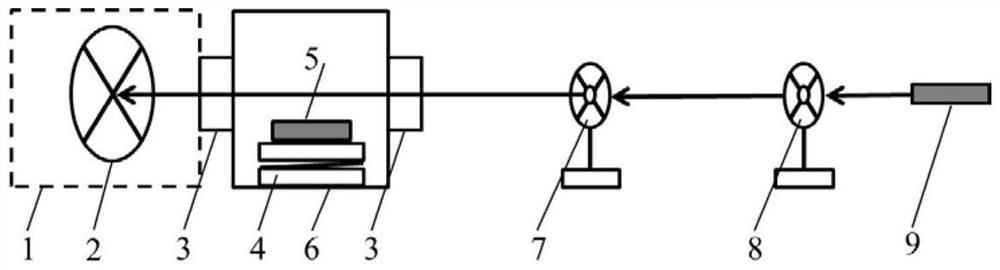

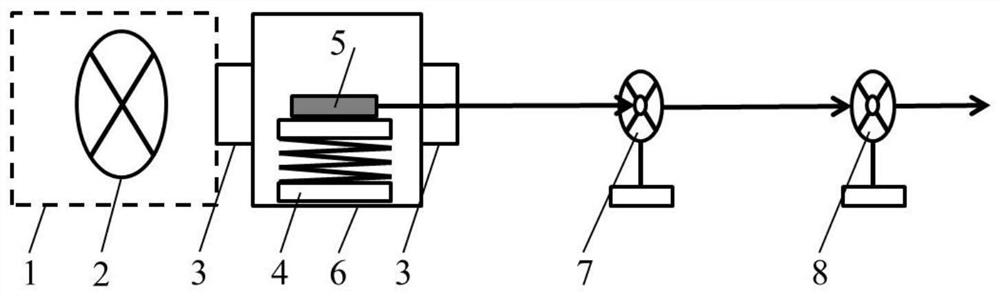

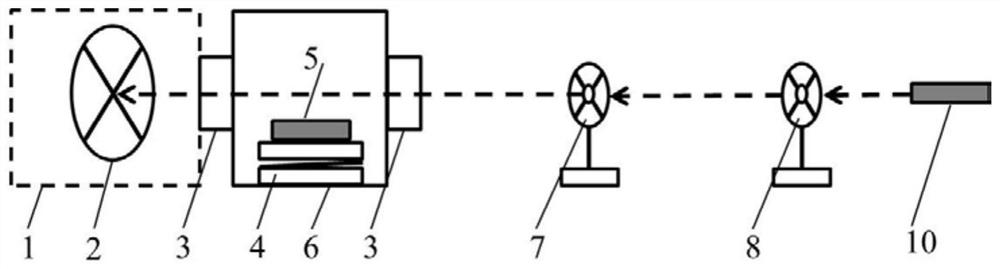

[0029] Such as Figure 1-Figure 3 As shown, one embodiment of the present invention is to propose a beam alignment device for an ultra-low temperature vacuum environment, including: an ultra-low temperature vacuum chamber body 1, an alignment target 2, a vacuum interface 3, a vacuum program-controlled displacement stage 4, and a guide Laser module 5, alignment device vacuum chamber body 6, first aperture 7, second aperture 8, laser module 9 for assembly and adjustment, and working light source 10; among them, vacuum program-controlled displacement stage 4, guiding laser module 5, alignment The vacuum chamber body 6 of the device together constitutes an external beam alignment module.

[0030] In the alignment device, a standard vacuum interface is provided on the same axis before and after the ultra-low temperature vacuum chamber body 1, and a vacuum program-controlled displacement table 4 is installed inside the ultra-low temperature vacuum chamber body 1, and a guiding laser...

Embodiment 2

[0036] On the basis of the above embodiments, the present invention also provides a beam alignment method for an ultra-low temperature vacuum environment, including a method for installing and debugging a beam alignment device and a beam alignment method, specifically including:

[0037] (1) Installation and debugging method of beam alignment device

[0038] The first step is to open the chamber of the ultra-low temperature vacuum device and adjust the position of the laser module before the ultra-low temperature refrigeration and vacuum pumping of the ultra-low temperature vacuum device and the beam alignment device, so that the laser module can be adjusted through the center of each vacuum interface and hit the Align the center of the target;

[0039]The second step is to close the chamber of the ultra-low temperature vacuum device and keep the position constant, set the first aperture and the second aperture in sequence on the optical path of the laser, and fix the position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com