Lithium ion battery synchronous lamination diaphragm cutting device and lithium ion battery manufacturing method

A lithium-ion battery cutting technology, applied to secondary batteries, circuits, electrical components, etc., can solve problems such as deviation, high repair rate, poor alignment, etc., to ensure quality, reduce repair rate, and reduce operation effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

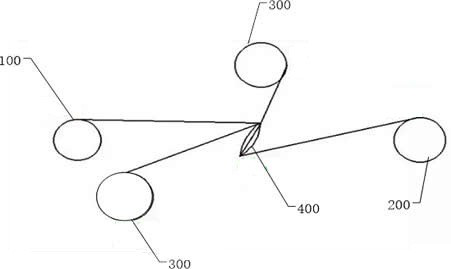

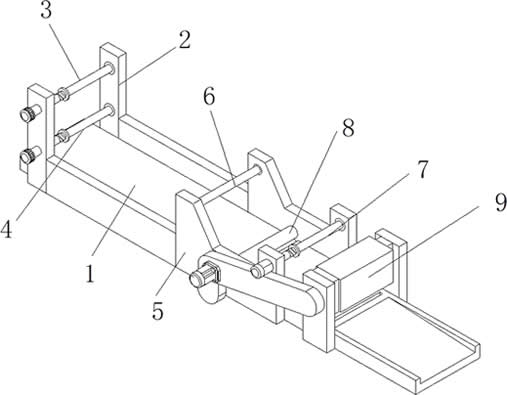

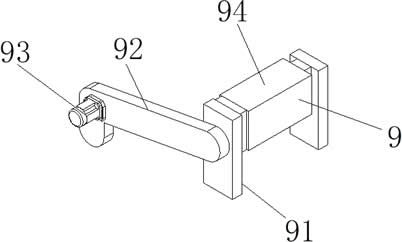

[0033] see figure 1 , the present invention provides a lithium-ion battery synchronous bonding diaphragm cutting device through improvement, including a support plate 1 and a cutting device 9, a first bracket 2 is installed on the left side of the top of the support plate 1, and the first bracket 2 has two upper and lower sides. The separator support roller 3 and the battery pole piece support roller 4 are respectively installed on the side, the second bracket 5 is installed in the middle of the top of the support plate 1, and the support roller 6 and the winding roller 7 are installed on the top of the left and right sides of the inner side of the second bracket 5. The middle part of the inner bottom end of the second bracket 5 is equipped with a pressure roller 8, and the right end of the second bracket 5 is provided with a cutting device 9, and the bottom end of the cutting device 9 is fixedly connected with the support plate 1, and the pressure roller 8 is provided with tw...

Embodiment 2

[0044] Another aspect of the present invention is to protect the lithium-ion battery manufacturing method using the above-mentioned lithium-ion battery synchronously laminating diaphragm cutting device, comprising the following steps:

[0045] S1. Preparation of the positive electrode sheet: take the strip-shaped positive electrode original roll and the first separator, use the above-mentioned lithium-ion battery synchronously laminating separator cutting device, and attach the first separator to the positive electrode original roll and according to the predetermined length Cutting to obtain the positive electrode sheet of the first shape;

[0046] S2. Preparation of the negative electrode sheet: Take the strip-shaped negative electrode original roll and the second separator, use the above-mentioned lithium-ion battery synchronously laminating the separator cutting device, attach the second separator to the negative electrode original roll and follow the schedule Length cuttin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com