Efficient paint spraying device for manufacturing and machining engineering machine

A kind of construction machinery and high-efficiency technology, which is applied in the direction of spraying device, spray booth, and surface coating liquid device, etc. It can solve the problems of inability to realize double-sided spraying operation, uneven paint coverage, spraying dead angle, etc., and achieve high efficiency and convenience Double-sided spraying, avoiding dead ends of spraying, and ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

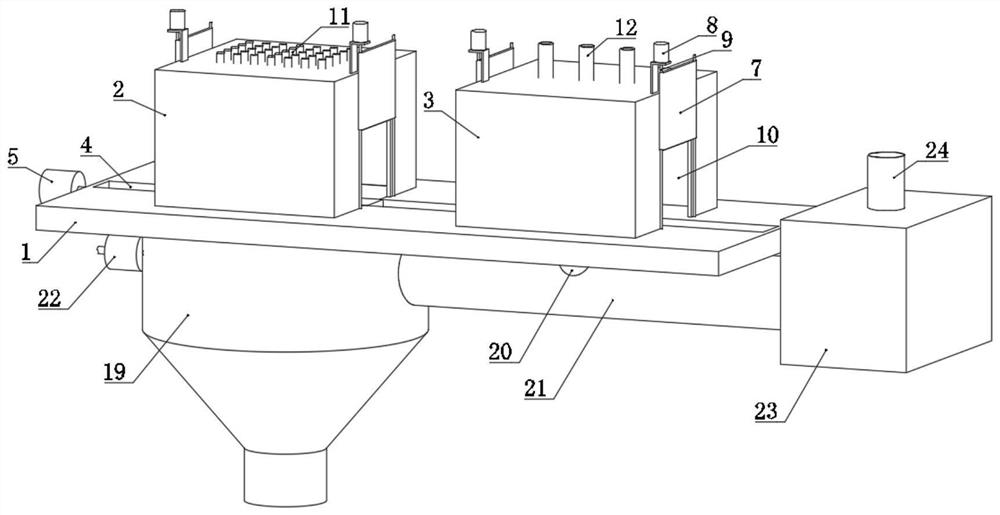

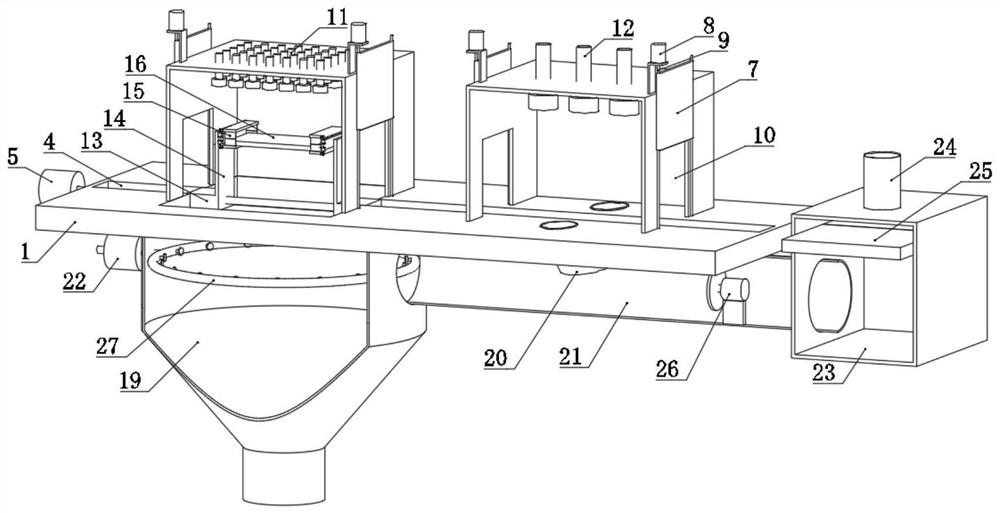

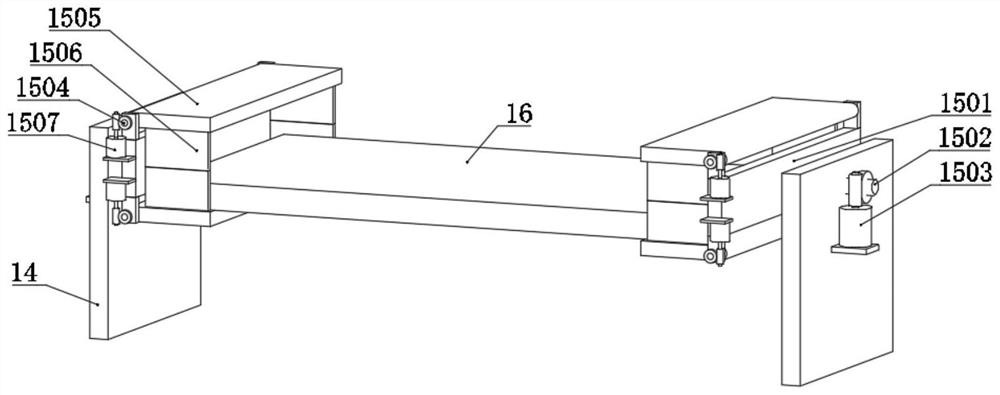

[0036] refer to Figure 1-8 , a high-efficiency painting device for construction machinery manufacturing and processing, including a substrate 1, a track groove 4 is opened on the top surface of the substrate 1, and a spraying box 2 and a drying box are respectively installed on the top surface of the substrate 1 and located at the front and rear sides of the track groove 4 3. The spraying box 2 and the drying box 3 are provided with a door opening 10 at the position corresponding to the track groove 4, and the door opening 10 is movably equipped with a door panel 7,

[0037] The door opening 10 and the door panel 7 size of the spraying box 2 places are equal to the door opening 10 and the door panel 7 size of the drying box 3 places. Wherein the size of the door panel 7 is slightly larger than the size of the door opening 10 to ensure that the door panel 7 can completely seal and cover the door opening 10 .

[0038] The front side of the door panel 7 is threaded with a lifti...

Embodiment 2

[0047] refer to Figure 1-8 In this second embodiment, on the basis of the first embodiment above, two rectangular grooves 17 are provided at the positions corresponding to the spraying box 2 on the substrate 1, and the two rectangular grooves 17 are symmetrically distributed on both sides of the track groove 4, and the substrate 1 Two air holes 18 are provided at the position corresponding to the drying box 3, and the two air holes 18 are symmetrically distributed on both sides of the track groove 4, and a purification box 19 is installed at the position corresponding to the two rectangular grooves 17 on the bottom surface of the substrate 1 to purify The bottom of case 19 is bucket-shaped and is equipped with drainpipe, and drainpipe is equipped with valve. The inner wall of the top of the purification box 19 is equipped with a circular pipe 27, the circular pipe 27 is connected with the water pump 22 through a pipeline, the water pump 22 is externally connected to the water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com