Mechanical assembling hand with contraction function

A shrinking function and shrinking mechanism technology, applied in the field of manipulators, can solve problems such as the limitation of the working range of the mechanical assembly hand, the limitation of the working ability of the mechanical assembly hand, and the reduction of the practicability of the mechanical assembly hand, so as to prevent separation, reduce friction, and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

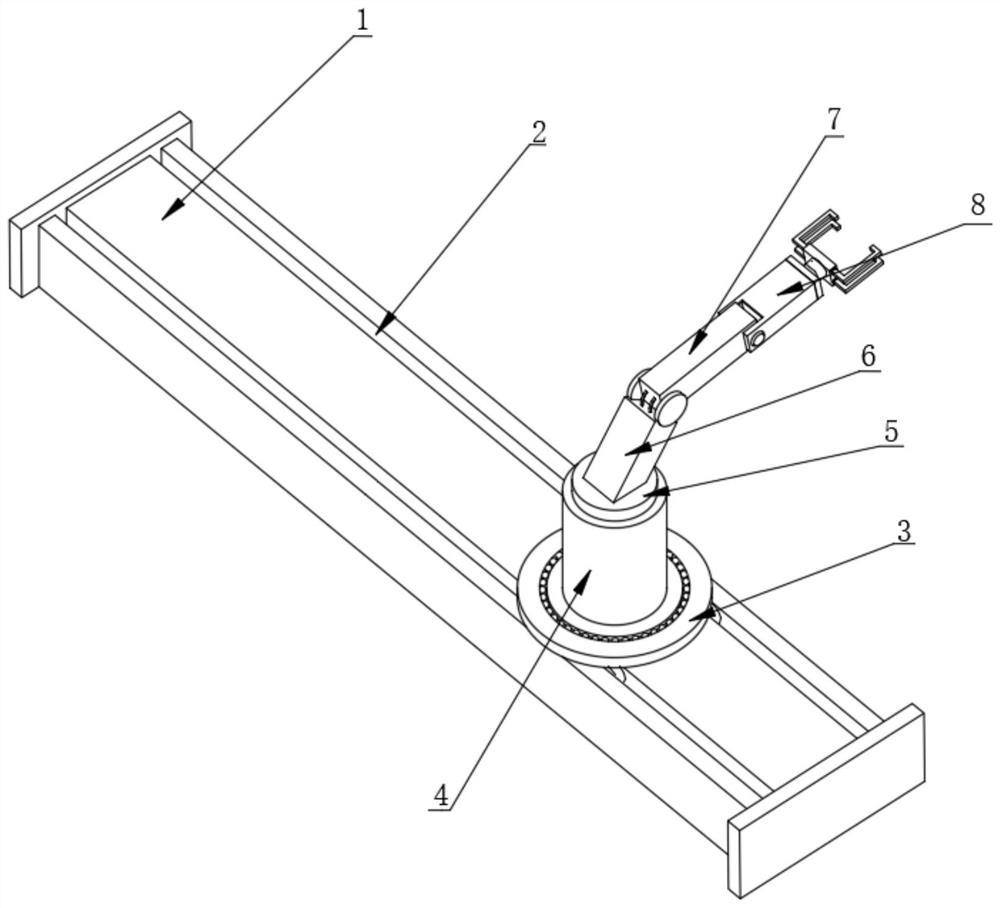

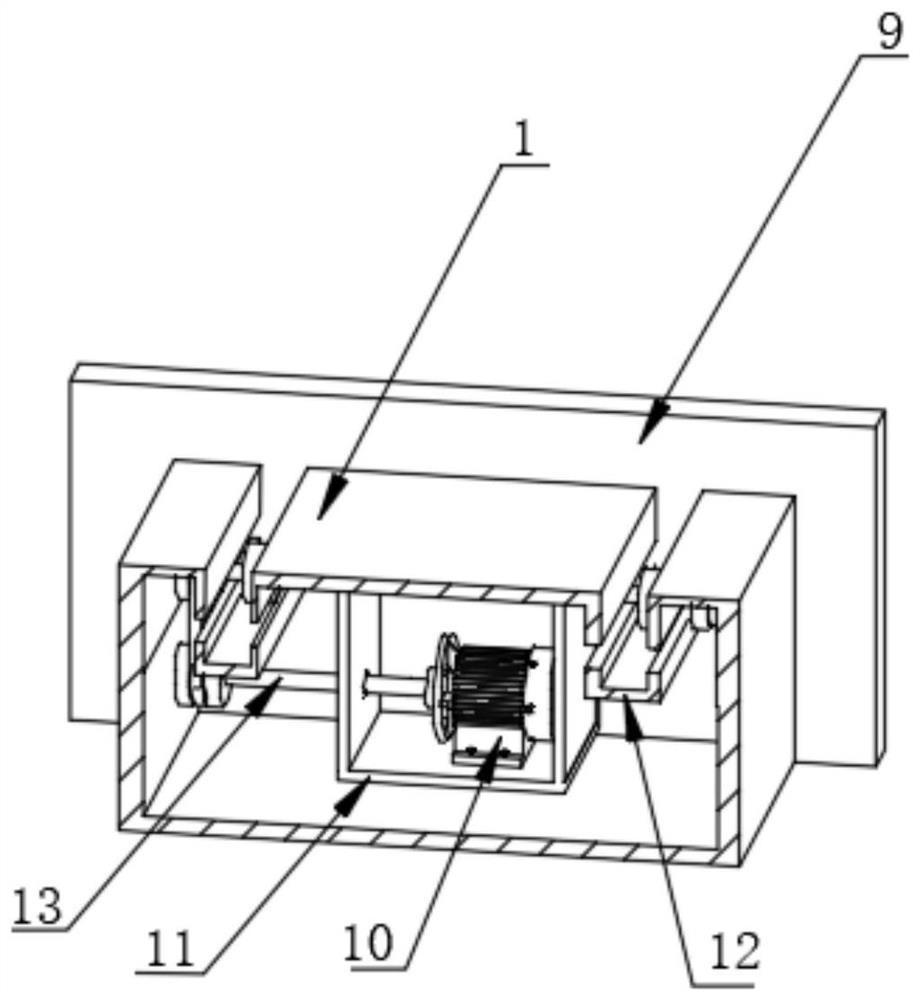

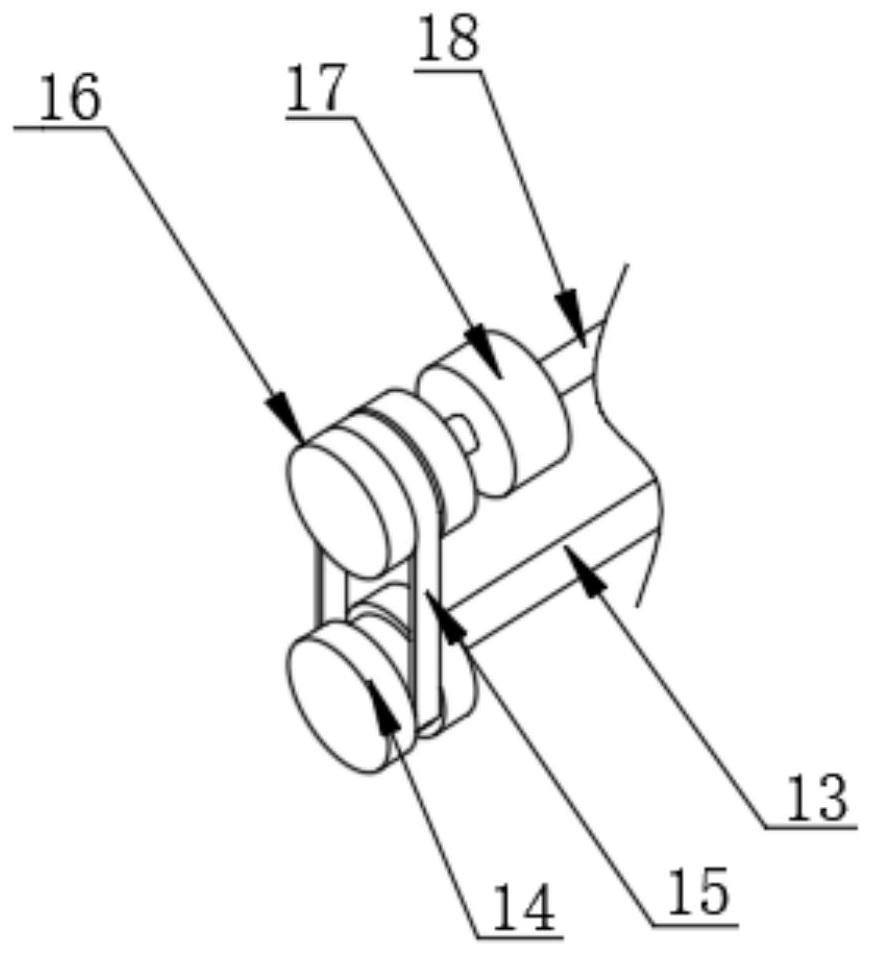

[0030]A mechanical assembly hand with contraction function, comprising a workbench 1, the upper surface of the workbench 1 is provided with a movable groove 2, the interior of the workbench 1 is fixedly installed with a sliding mechanism, and the upper surface of the movable groove 2 is provided with a moving block 3, The upper surface of the moving block 3 is provided with a rotating column 4, the upper surface of the rotating column 4 is fixedly connected with a connecting block 5, the upper surface of the connecting block 5 is fixedly connected with a large mechanical arm 6, and the upper end of the large mechanical arm 6 is movably connected with a small mechanical arm. One side of the outer surface of the arm 7 and the small mechanical arm 7 is provided with a telescopic column 8, and a retractable mechanism is installed inside the telescopic column 8. The sliding mechanism includes a protective shell 11, and a first motor 10 is fixedly installed inside the protective shell...

Embodiment 2

[0032] Embodiment 2: the difference based on Embodiment 1 is;

[0033] The upper surface of the moving block 3 is fixedly connected with a clamping block 19, and the inside of the moving block 3 is fixedly equipped with a center ball 24, and the lower surface of the rotating column 4 is fixedly connected with a rotating block 20, and the middle part of the rotating block 20 is provided with a clamping hole. The outer surface of the block 20 is provided with a clamping ring, one side of the outer surface of the center ball 24 is movably socketed in the clamping ring, the clamping block 19 is movably clamped with the clamping hole, and the inside of the rotating column 4 is fixedly equipped with a fixed block 21 , the inside of the fixed block 21 is fixedly installed with a second motor 25, the upper end of the second motor 25 is fixedly connected with a rotating gear 26, and the lower surface of the connecting block 5 is fixedly connected with a snap ring 27, and the middle part...

Embodiment 3

[0035] Embodiment 3: the difference based on embodiment 1 is;

[0036] The retraction mechanism includes a hydraulic press 30, one side of the outer surface of the hydraulic press 30 is fixedly connected with a closing plate 29, one side of the outer surface of the closing plate 29 is provided with an air inlet, and the other side of the outer surface of the hydraulic press 30 is fixedly connected with a movable column 33, The inside of the movable column 33 is movably connected with a telescopic rod 37, the outer surface of the telescopic rod 37 is provided with a return spring 31, the other end of the return spring 31 is fixedly connected with a sliding block 34, and the other side of the outer surface of the sliding block 34 is provided with a fixed plate 32, the other side of the outer surface of the fixed plate 32 is provided with a connecting plate 35, the two ends of the connecting plate 35 are fixedly connected with claws 36, the inside of the fixed plate 32 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com