PVC glove with pitted fingers and preparation process thereof

A preparation process and technology of PVC resin powder, applied in gloves, clothing, protective clothing, etc., can solve the problems of insufficient tensile strength, poor high temperature resistance, limited use range, etc., and achieve good service life, good quality, and safe use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

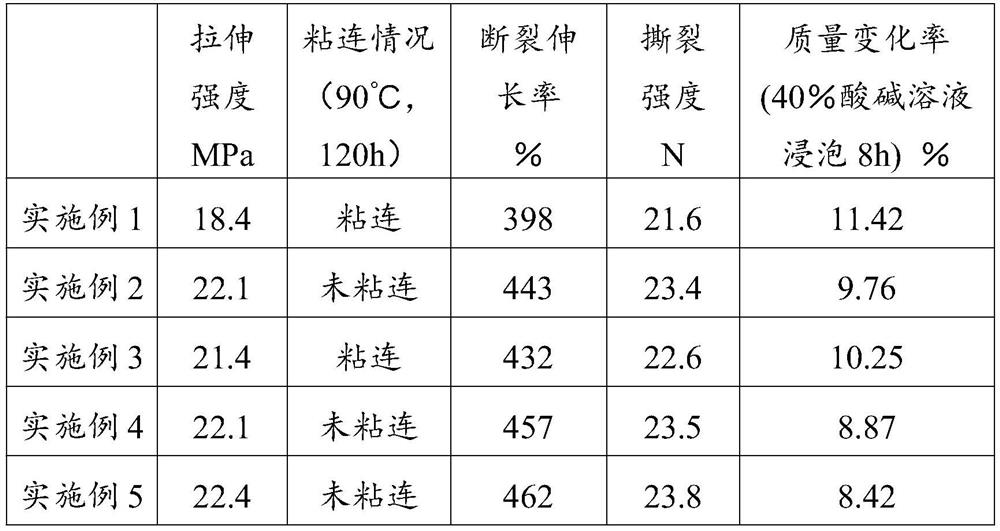

Examples

Embodiment 1

[0023] The invention provides a PVC finger hemp glove, wherein the main materials include: 95 parts of PVC resin powder, 12 parts of polyether ether ketone fiber, 8 parts of phenolic carbon fiber, 20 parts of acetyl tributyl citrate, 3 parts of adhesive, 4 parts of stabilizer, 1 part of CZ accelerator and 1 part of vulcanizing agent.

[0024] Further, in the above technical solution, the stabilizer is a calcium-zinc composite heat stabilizer, and the vulcanizing agent is sulfur.

[0025] A preparation process of PVC finger hemp gloves, the concrete operation steps are:

[0026] Step 1: Wash and dry the polyetheretherketone fiber and the phenolic carbon fiber with 10% Nacl solution, and cut into sections after drying;

[0027] Step 2: After mixing acetyl tributyl citrate, stabilizer and CZ accelerator, add an appropriate amount of water and stir for 30 minutes, then add PVC resin powder and vulcanizing agent, and stir evenly;

[0028] Step 3: After mixing the short fibers obt...

Embodiment 2

[0037] The invention provides a PVC finger hemp glove, wherein the main materials include: 100 parts of PVC resin powder, 15 parts of polyether ether ketone fiber, 10 parts of phenolic carbon fiber, 20 parts of acetyl tributyl citrate, 3 parts of adhesive, 4 parts of stabilizer, 1 part of CZ accelerator and 1 part of vulcanizing agent.

[0038] Further, in the above technical solution, the stabilizer is a calcium-zinc composite heat stabilizer, and the vulcanizing agent is sulfur.

[0039] A preparation process of PVC finger hemp gloves, the concrete operation steps are:

[0040] Step 1: Wash and dry the polyetheretherketone fiber and the phenolic carbon fiber with 10% Nacl solution, and cut into sections after drying;

[0041] Step 2: After mixing acetyl tributyl citrate, stabilizer and CZ accelerator, add an appropriate amount of water and stir for 30 minutes, then add PVC resin powder and vulcanizing agent, and stir evenly;

[0042] Step 3: After mixing the short fibers o...

Embodiment 3

[0051] The invention provides a PVC finger hemp glove, wherein the main materials include by weight: 100 parts of PVC resin powder, 18 parts of polyether ether ketone fiber, 12 parts of phenolic carbon fiber, 20 parts of acetyl tributyl citrate, 3 parts of adhesive, 4 parts of stabilizer, 1 part of CZ accelerator and 1 part of vulcanizing agent.

[0052]Further, in the above technical solution, the stabilizer is a calcium-zinc composite heat stabilizer, and the vulcanizing agent is sulfur.

[0053] A preparation process of PVC finger hemp gloves, the concrete operation steps are:

[0054] Step 1: Wash and dry the polyetheretherketone fiber and the phenolic carbon fiber with 10% Nacl solution, and cut into sections after drying;

[0055] Step 2: After mixing acetyl tributyl citrate, stabilizer and CZ accelerator, add an appropriate amount of water and stir for 30 minutes, then add PVC resin powder and vulcanizing agent, and stir evenly;

[0056] Step 3: After mixing the short...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com