Double ducted ejector for aeroengine

An aero-engine and ducting technology, which is applied in the direction of rocket engine devices, machines/engines, jet propulsion devices, etc., can solve the problems of unchangeable working conditions, inability to separate internal and external exhaust, etc., so as to improve kinetic energy and ejection efficiency and gas mixing uniformity, and improve the effect of ejection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

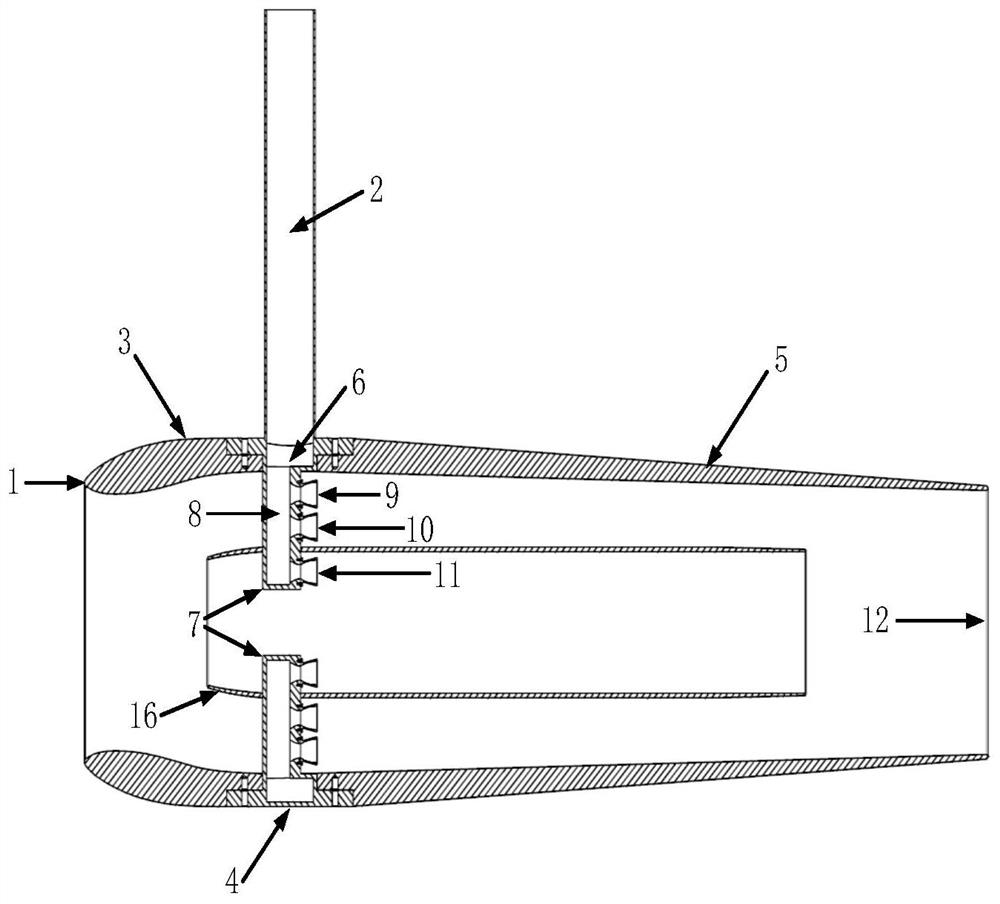

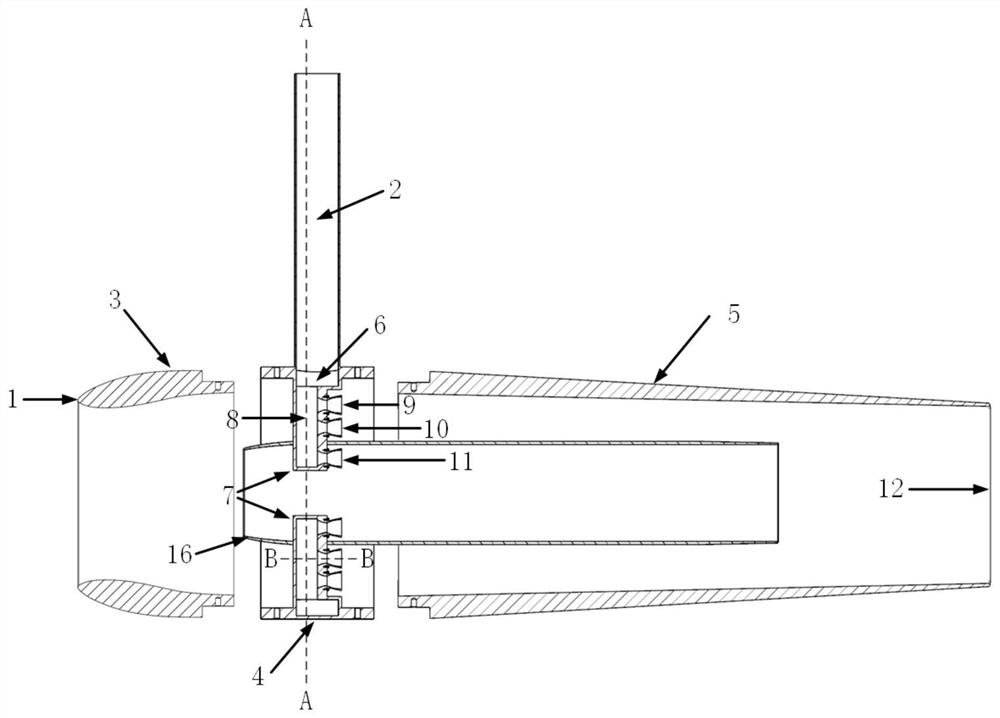

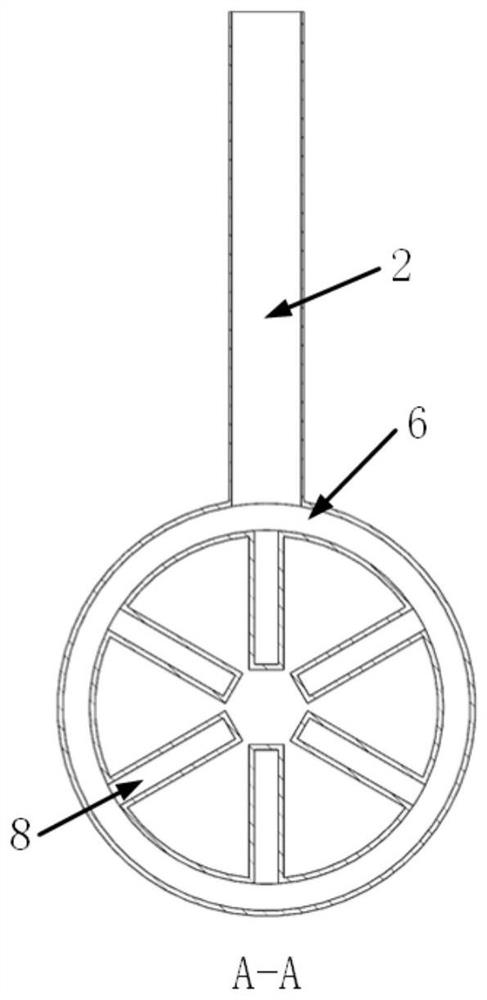

[0037] This embodiment is a dual-duct ejection device for aero-engines, including a high-pressure air intake duct 2, an ejector, an inner duct body 16, a leading edge stabilizer 7 and a variable Mach number nozzle. The ejector is used as the outer channel body, and the inner channel body is located in the ejector.

[0038] The ejector is divided into an ejector front section 3 , an ejector middle section 4 and an ejector rear section 5 . There are six said steady flow branch plates 7, and the airflow inlet end of each steady flow branch plate is welded to the inner surface of the shell of the middle section 4 of the ejector, and is connected to the annular high-pressure gas source on the middle section of the ejector. The chamber 6 is communicated; the closed end of each flow-stabilizing branch plate 7 passes through the flow-stabilizing branch plate insertion hole on the shell of the inner channel body 16 and extends into the inner channel body. The inner channel body is wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com