Gas heating furnace capable of achieving utilization of waste heat

A technology of gas and waste heat, which is applied in heating fuel, water heater/stove, household stove/stove, etc., and can solve problems such as potential safety hazards, insufficient combustion, and accumulation of carbon monoxide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

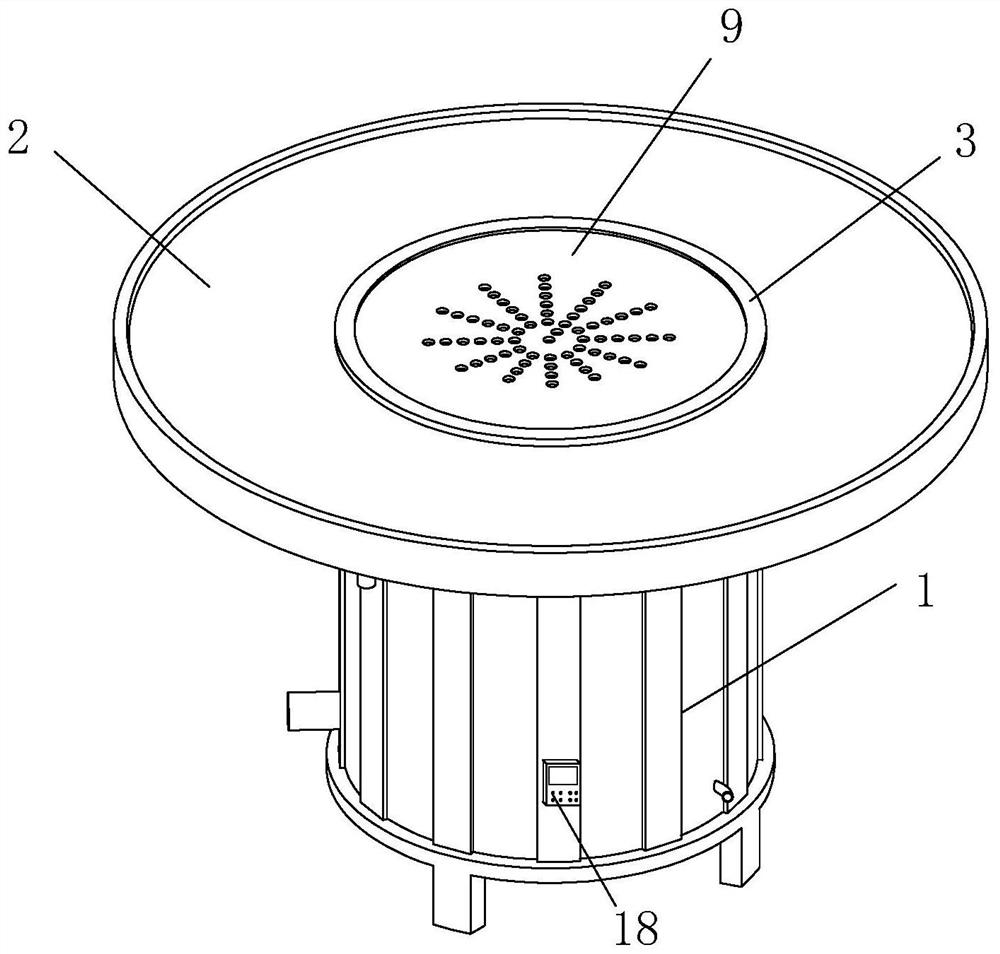

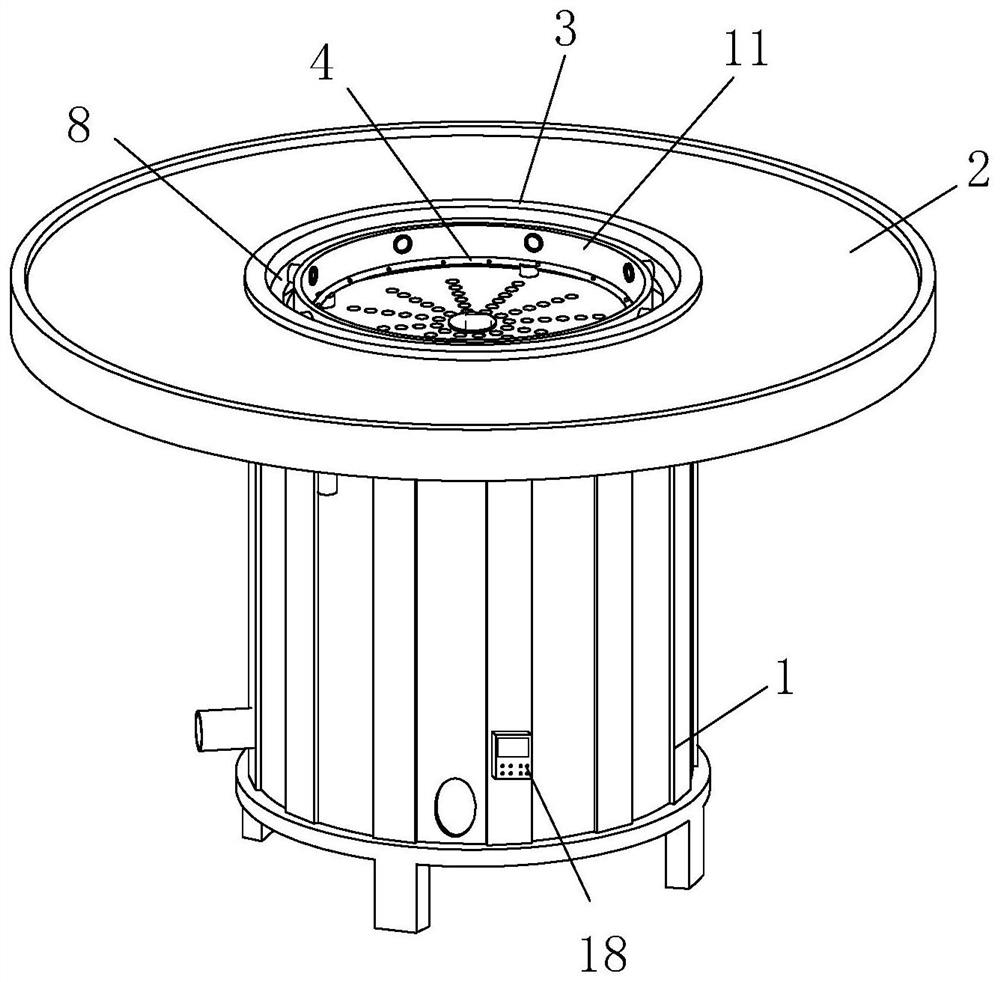

[0038] A gas heating stove that can use waste heat, such as figure 1 , figure 2 As shown, it includes a furnace body 1, a table top 2 and a brazier 3, the table top 1 is fixedly connected to the top of the furnace body 1, the brazier 3 is embedded in the center of the table top 1, and a baffle with a through hole on the surface is placed on the top of the brazier 3 9, and the interior of the brazier 3 is provided with a combustion device 4 .

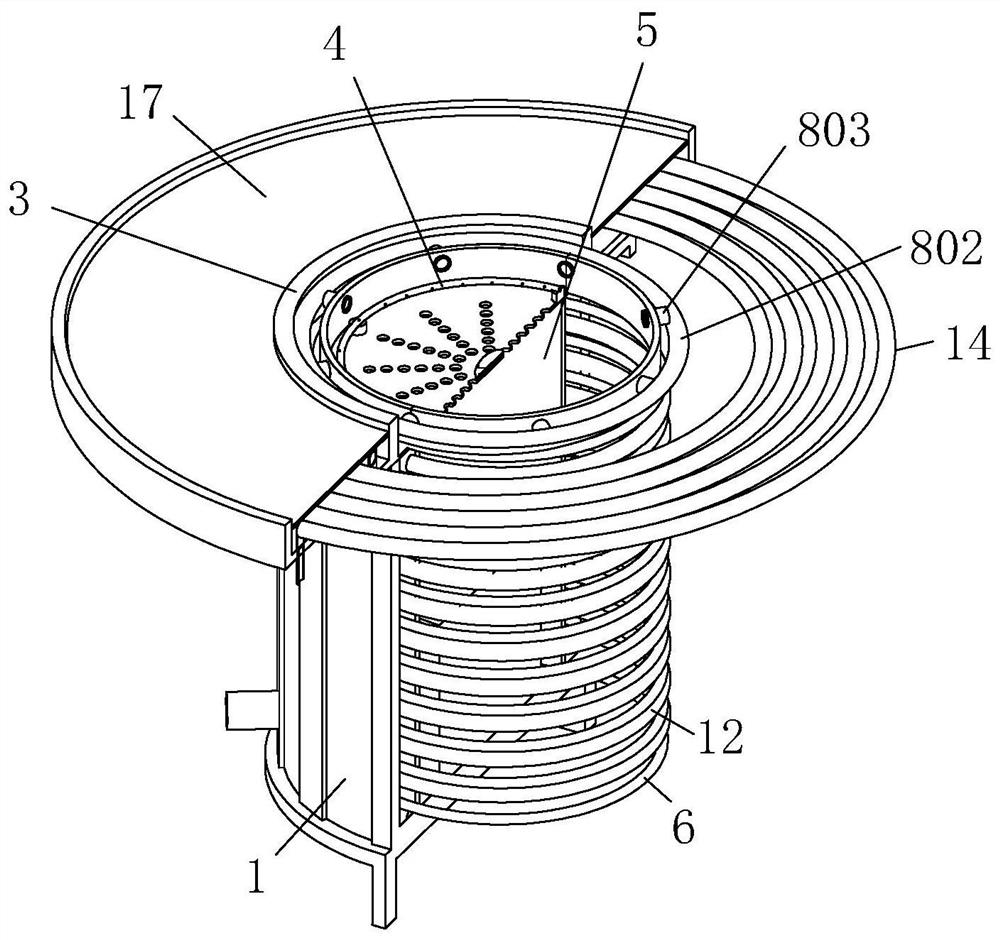

[0039] Such as image 3 , Figure 4 The inner furnace 5 shown in the furnace body 1 is fixedly installed, and the surface of the inner furnace 5 is coiled with a preheating pipe 6, and one end of the preheating pipe 6 is connected with the brazier 3, and is used for providing gas for the combustion device 4, preheating The other end of the pipe 6 runs through the furnace body 1 and extends outside the furnace body ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap