Heliostat driving device

A driving device and heliostat technology, which is applied in the field of solar power generation, can solve the problems of high manufacturing cost, large area of the mirror field, and complex structure of the heliostat driving device, so as to reduce frictional resistance, simplify the structure, and improve the photoelectricity. The effect of conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below with reference to the accompanying drawings.

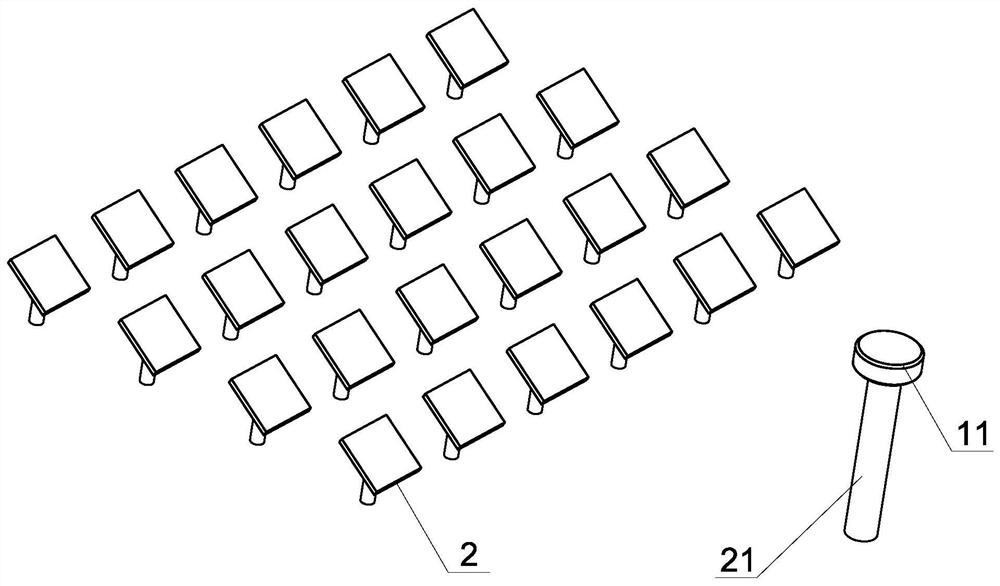

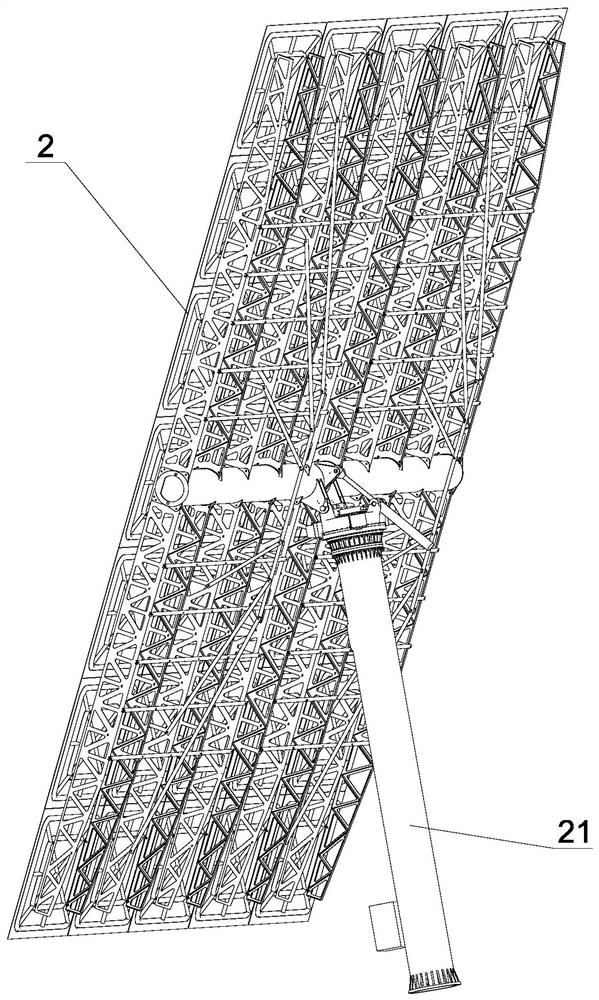

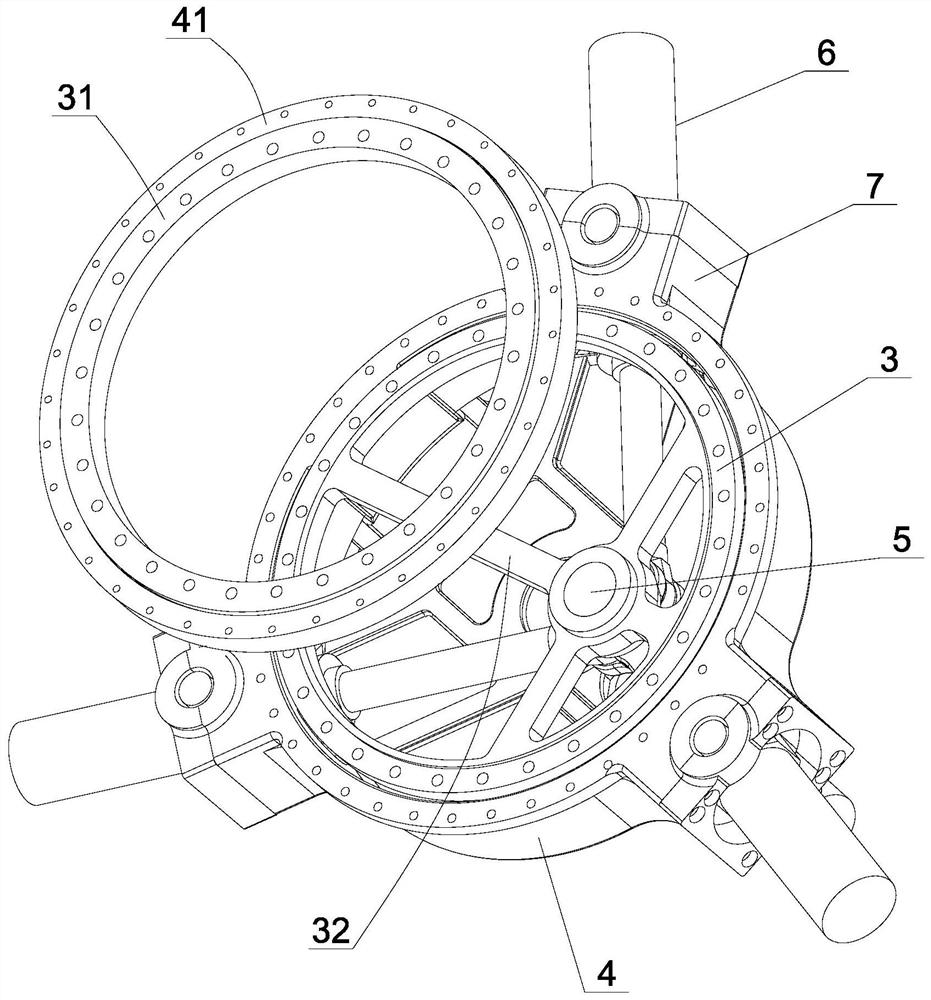

[0038] like figure 1 As shown, a fixed day mirror driving device is suitable for solar thermal power generation systems as a solar thermal power generation system, which includes a collecting tower 1, a heat absorber 11 set in the upper end of the collecting tower, numerous towards a collecting tower Set of fixed day mirrors 2, fixed day mirrors reflect the sun light to the heat absorber of the collector tower, of course, the day is disposed on the column 21. The present invention includes a horizontal rotary drive for driving the level of fixed day mirrors to drive a pitch driving device that rotates in a vertical plane, and swinging through the level of fixed day mirrors, which can make the fixed day mirror The sun rays are tracked according to the geographic latitude of the location, to ensure that the sun is reflected onto the heat absorber of the collecting tower.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com