LED display module and LED display screen

A technology for display modules and circuits, applied in circuit shape/layout, instruments, electrical components, etc., can solve the problems of limited layout of driver ICs, not involving driver chip layout, limitations, etc., to optimize layout, reduce Production cost, the effect of reducing heat concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

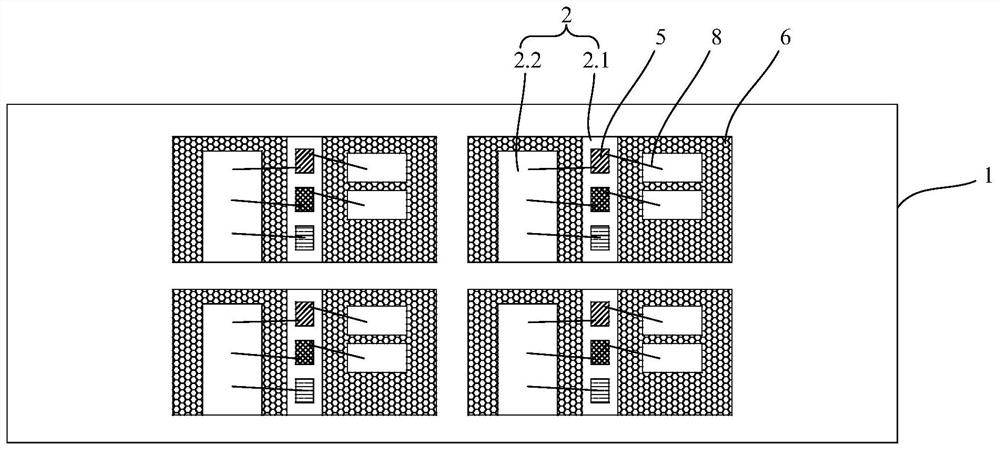

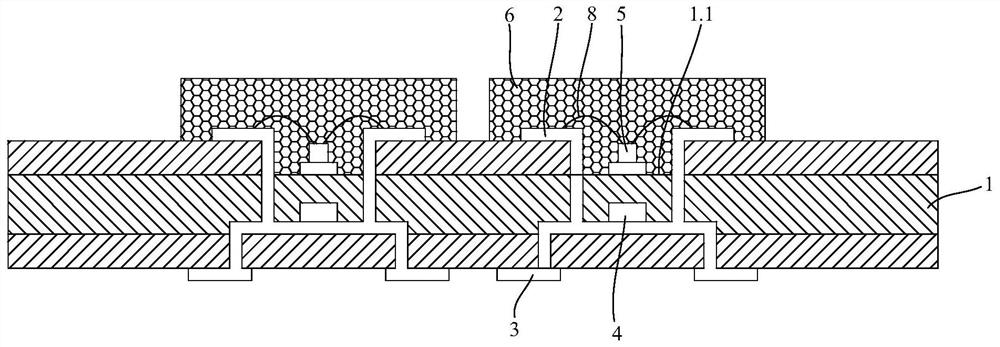

[0038] like figure 1 with figure 2 As shown, the structure of the LED display module of the present invention regarding the first embodiment. One of the LED display modules in the present invention includes a PCB substrate 1, and a front-side fixing provided with a front line 2 having a front line 2, and the back surface of the PCB substrate 1 is fixedly provided with a back line 3. The front lines 2 are The back line 3 is electrically connected, the PCB substrate 1 is fixedly provided with a drive chip 4, and the drive chip 4 is electrically connected to the front line 2 and the back line 3, and fixed settings on the PCB substrate 1 There is a light-emitting chipset 5, the light-emitting chipset 5 is electrically connected to the front line 2, and the PCB substrate 1 is also provided with encapsulation of the encapsulation of the light-emitting chipset 5 and the front line 2.

[0039] During the actual application, the lower side of each set of light-emitting chipset 5 is arrange...

Embodiment 2

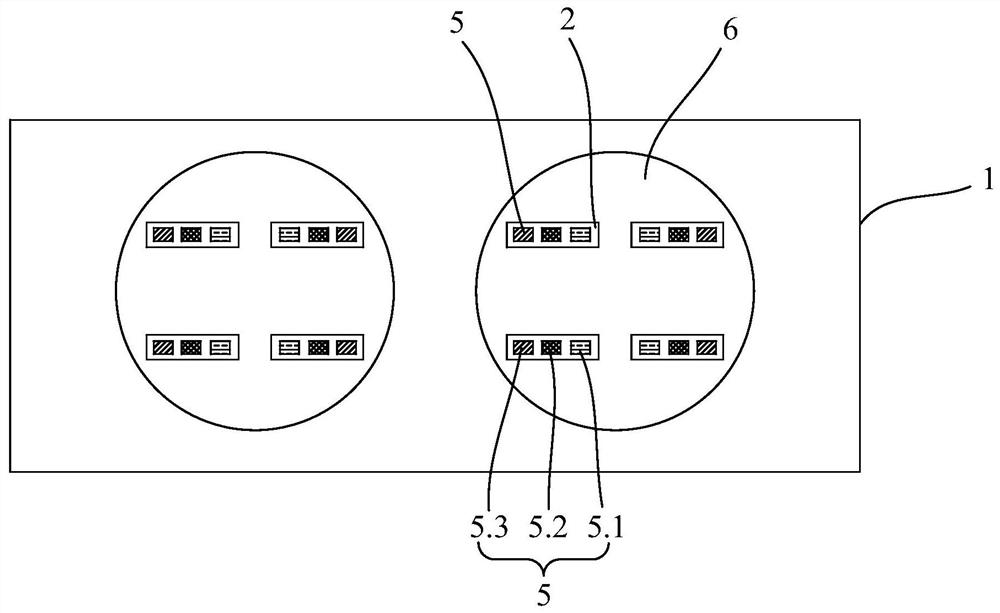

[0055] like image 3 with Figure 4 As shown, the structure of the LED display module of the present invention regarding the second embodiment. The present embodiment differs from the first embodiment in that each of the grooves 1.1 is equipped with a plurality of sets of light-emitting chip sets 5, and the plurality of sets of light-emitting chip sets 5 are flipped on the front line 2, and adjacent two The light-emitting chipset 5 is arranged between the light-emitting chipset 5 and the front lines 2 are in the groove 1.1. Specifically, the light-emitting chipset 5 is fixed to the front line 2 by tin or eutectic solder, each of which is electrically connected to a drive chip 4 through the front line 2.

[0056] Further, the light-emitting chipset 5 includes a red light chip 5.1, a green chip 5.2, and a blue chip 5.3, the red light chip 5.2, and the blue chip 5.3 are fixed to the solid crystal region 2.1, The red light chip 5.1, the green chip 5.2, and the blue chip 5.3 are fixed to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com