Multi-output-shaft type independent voltage regulation variable frequency motor

A technology of multiple output shafts and variable frequency motors, applied in the direction of electromechanical devices, electrical components, shielding electromagnetic fields, etc., can solve the problems of low winding utilization, large end loss, large motor volume, etc., and achieve wide speed adjustment range and good speed Adjustability and wide application scenarios

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

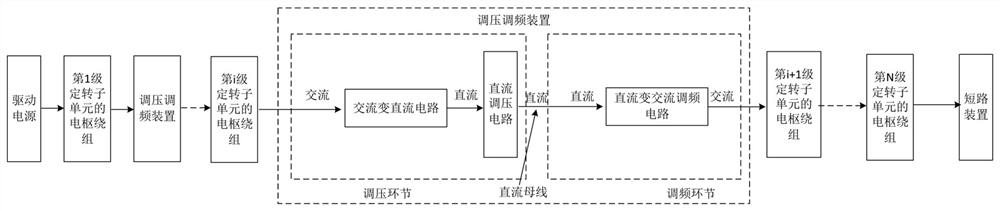

[0043] This embodiment provides a multi-output shaft variable-frequency variable-voltage speed-regulating motor, such as figure 1 As shown, it includes N stator-rotor units nested in sequence, each stator-rotor unit has an output shaft 11, and the output shafts 11 of any two adjacent stator-rotor units are arranged on different sides of the motor; preferably, In this embodiment, the stator and rotor units are sorted from the inside to the inside, the innermost stator and rotor unit is the first stator and rotor unit, and the outermost stator and rotor unit is the Nth stator and rotor unit;

[0044] A voltage regulation and frequency modulation device is connected in series between the armature windings of two adjacent stator and rotor units. The armature winding input terminal of the first stator and rotor unit is connected to the drive power supply, and the armature winding of the i-th stator and rotor unit is connected to the input line. terminal is connected to the outlet e...

Embodiment 2

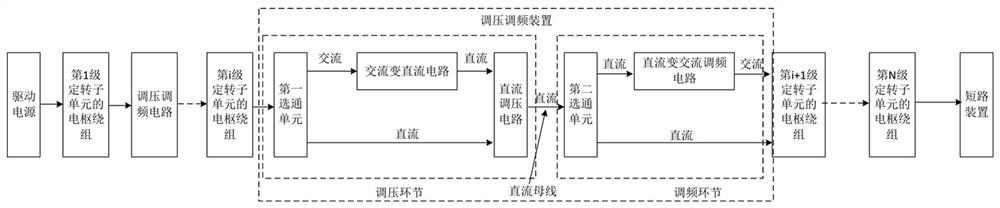

[0057] The difference between this embodiment and embodiment 1 is: as figure 2 As shown, the voltage regulating circuit also includes a first gating unit, the first terminal of the first gating unit is connected to the armature winding outlet end of the i-1th stator and rotor unit, and the first gating unit The second terminal of the first gate unit is directly connected to the DC voltage regulator circuit through the AC to DC circuit, and the third terminal of the first gating unit is directly connected to the DC voltage regulator circuit; The conduction and disconnection between the i-1th stator-rotor unit’s armature winding output terminal to realize the alternating current into direct current and send it to the DC voltage regulating circuit, or the i-1st stator-rotor unit When the armature winding of the unit outputs direct current, the direct current is directly sent to the direct current voltage regulating circuit;

[0058] The frequency modulation circuit also include...

Embodiment 3

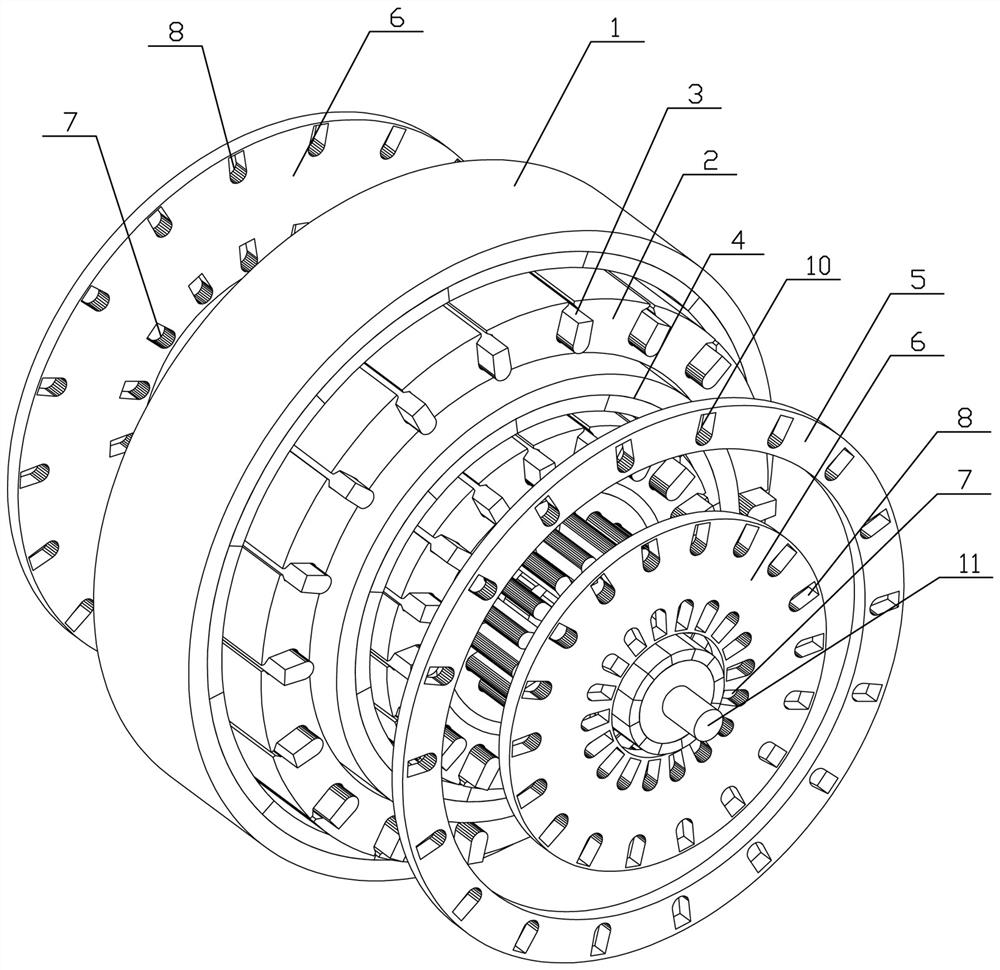

[0075] The difference between this embodiment and embodiment 1 or 2 is: as image 3 and Figure 4 As shown, the innermost stator-rotor unit is an inner-rotor outer-stator structure, and the remaining stator-rotor units are an outer-rotor inner-stator structure; a magnetic isolation ring 4 is embedded between the innermost stator-rotor unit and its adjacent stator-rotor unit .

[0076] The magnetic circuit of the stator and rotor 1 of the inner stator and rotor unit and the outer stator and rotor unit can be isolated by the magnetic isolation ring 4, so that the magnetic circuits of the stator and rotor 1 of the two layers of the stator and rotor unit of the motor do not interfere with each other, Furthermore, independent control of different operating frequencies of rotors 1 of different layers can be realized through the independent interlayer conductors provided at the ends to transfer the frequency conversion drive end rings, so as to realize the independent operation of d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com