Production system for removing VOC (Volatile Organic Compounds) from polyether polyol

A polyether polyol and production system technology, applied in flash evaporation, vacuum distillation, steam distillation, etc., can solve the problems of limited removal effect and long operation cycle, and achieve the effect of low gas volume and strong process adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

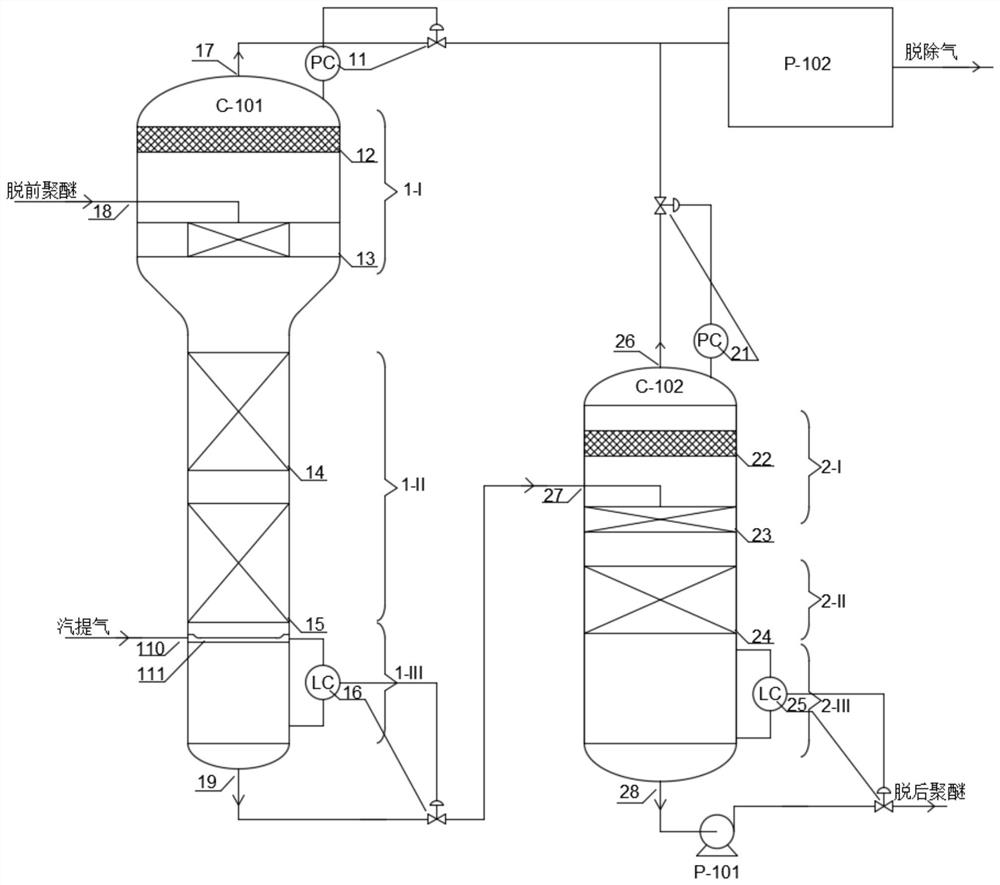

[0020] A production system for removing VOC from polyether polyols, including a stripping tower, a flash tower, an outgoing pump, and a vacuum unit;

[0021] The stripper comprises three parts, a deceleration section, a stripping section and a tower still section. An external jacket or an external heat tracing pipe is provided, and 0.1-1.0 MPa (G) saturated steam is used for heat tracing. In this embodiment, 0.2-0.5 MPa (G) saturated steam is preferably used.

[0022] The diameter ratio of the deceleration section and the stripping section is 1.2:1 to 2:1. The deceleration section is used to reduce the superficial gas velocity, reduce mist entrainment, and increase product yield. The diameter ratio is selected according to the size of the mist droplet to ensure that the degassed phase leaves the tower body, while the polyether polyol product remains In the tower, product loss is reduced.

[0023] In this embodiment, the demister section of the stripping tower includes a demi...

Embodiment 2

[0059] like figure 1 As shown, a production system for removing VOC from polyether polyols includes a stripper C-101, a flash tower C-102, an external delivery pump P-101, and a vacuum unit P-102.

[0060] There are three sections in the stripping tower, which are deceleration section 1-I, stripping section 1-II, and tower kettle section 1-III, and include at least four material ports, at least one pressure control loop 11 and one Liquid level control circuit 16.

[0061] According to requirements, a pre-stripping polyether inlet 18 and a gas phase outlet 17 are arranged at the top of the stripper, and a polyether outlet 19 and a stripping gas inlet 110 are arranged at the bottom.

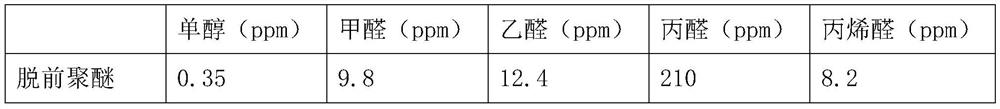

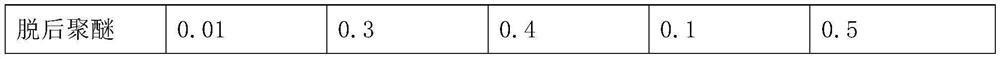

[0062] The stripping polyether enters the stripping tower from the top of the tower, and the stripping gas enters the stripping tower from the bottom of the tower, and contacts in countercurrent in the tower to remove small molecular substances containing odor. The polyether flows out from the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com