Bread made from rice flour and preparation method thereof

A rice flour and bread technology, applied in application, food preparation, baked food, etc., can solve the problem of gluten allergy patients not being able to eat, and achieve the effects of good product quality, easy operation and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

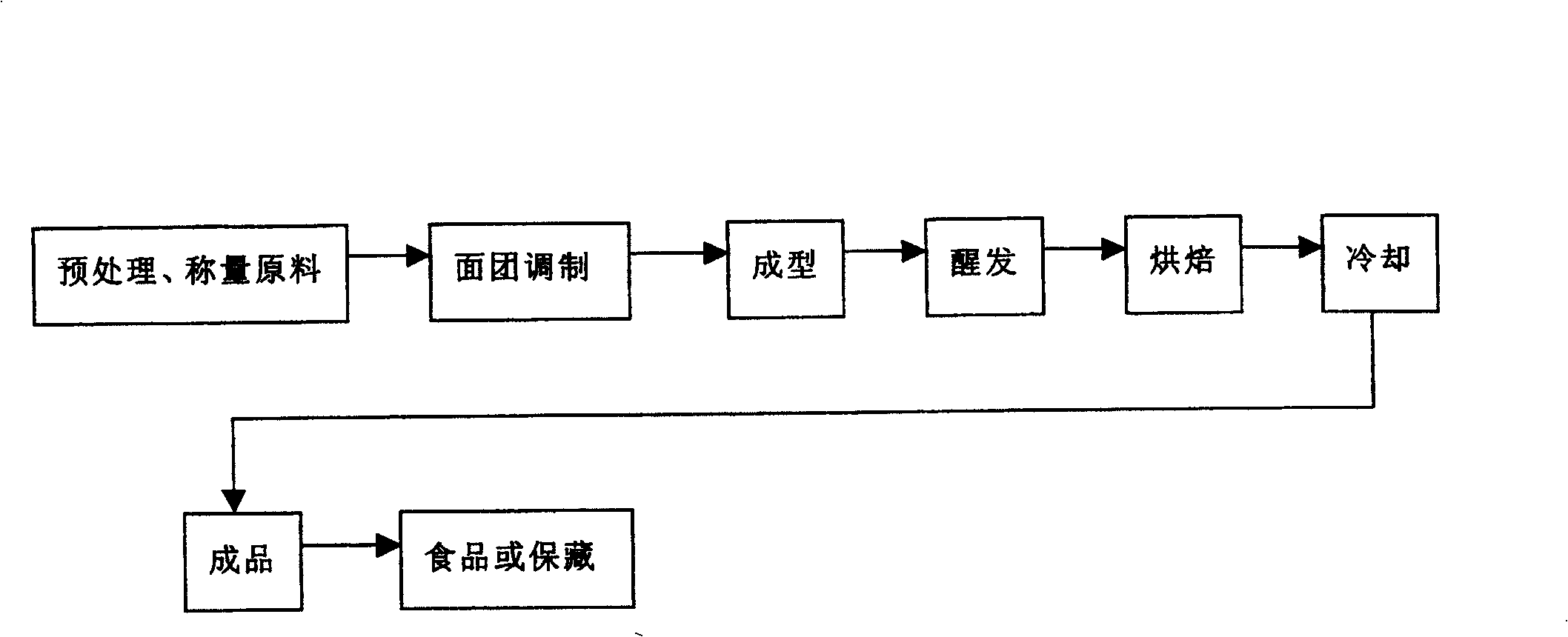

Image

Examples

Embodiment 1

[0020] Pretreatment of auxiliary materials: crush fresh rice to 130 mesh for later use; take 1.0% of yeast and dissolve (activate) it with 3 times 25°C water in advance to form a yeast solution; take 1.6% of hydroxypropyl methylcellulose (HPMC) for edible gum 5 times of hot water to dissolve into a solution, and set aside after cooling.

[0021] Dough preparation and fermentation: rice flour: 38.0% (13% water base), pregelatinized starch (α-starch): 5.1% (14% water base), salt: 1.4%, white sugar: 2.9% %, salad oil: 1.7%, shortening: 0.2%, water: 46.5% (including activated yeast and dissolved hydroxypropyl methylcellulose solution), monoglyceride: 1.0%, SSL (stearin Sodium acyl lactate) is: 0.6% is added to the dough mixer, 80r / min speed is stirred and kneaded for 3 minutes; then the activated yeast solution is added, and 80r / min is used to stir and knead for 3 minutes; finally, edible gum hydroxypropyl Methyl cellulose (HPMC) solution, stirring and kneading for 3 minutes at 1...

Embodiment 2

[0026] Weighing: Accurately weigh 37.4% (13% water base) rice flour, 2.8% (14% water base) pregelatinized starch (α-starch), 1.2% salt, 3.3% white granulated sugar, 2.1% salad oil, 0.4 % shortening, 2.3% hydroxypropyl methylcellulose (HPMC), 47.0% water (including activated yeast and dissolved hydroxypropyl methylcellulose solution), 1.4% monoglyceride, 1.0% SSL (stearyl Sodium Lactate), Yeast 1.1%.

[0027] Pretreatment of raw and auxiliary materials: fresh rice is crushed to 140 mesh for later use; yeast is pre-dissolved (activated) with 4 times of 28°C water; edible gum is dissolved with 6 times of 85°C hot water, cooled for later use.

[0028] Dough preparation and fermentation:

[0029] Add the processed rice flour, sugar, salt, oil, etc. into the dough mixer according to the recipe requirements, stir and knead at a speed of 90r / min for 4 minutes; then add the activated yeast, stir and knead at a speed of 90r / min for 4 minutes; Finally, add edible gum and stir at 110r / m...

Embodiment 3

[0034] Weighing: Accurately weigh 39.0% (13% water base) rice flour, 1.6% (14% water base) pregelatinized starch (α-starch), 1.6% salt, 3.1% white granulated sugar, 1.9% salad oil, 0.6 % shortening, 1.9% hydroxypropyl methylcellulose (HPMC), 48.3% water (including activated yeast and dissolved hydroxypropyl methylcellulose solution), 1.2% monoglyceride, 0.8% SSL (stearyl sodium lactate).

[0035] Pretreatment of raw materials:

[0036] Fresh rice is crushed to 150 mesh for later use; yeast is pre-dissolved (activated) with 5 times of 30°C water; edible gum is dissolved with 7 times of 95°C hot water, and then cooled for later use.

[0037] Dough preparation and fermentation:

[0038] Add the processed rice flour, sugar, salt, oil, etc. into the dough mixer according to the recipe requirements, stir and knead at 100r / min for 5 minutes; then add the activated yeast, stir and knead at 100r / min for 5 minutes; Finally, add edible gum and stir at a speed of 120r / min for 5 minutes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com