Preparation method of paper-making reconstituted tobacco leaves for reducing CO content in mainstream smoke

A technology for reconstituted tobacco leaves and mainstream smoke, which is applied in the field of tobacco product production, can solve the problems such as the increase of CO emission in the smoke of reconstituted tobacco leaves, and achieves the effect of strong adaptability and wide range of sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

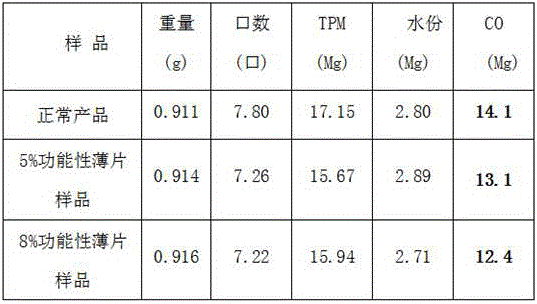

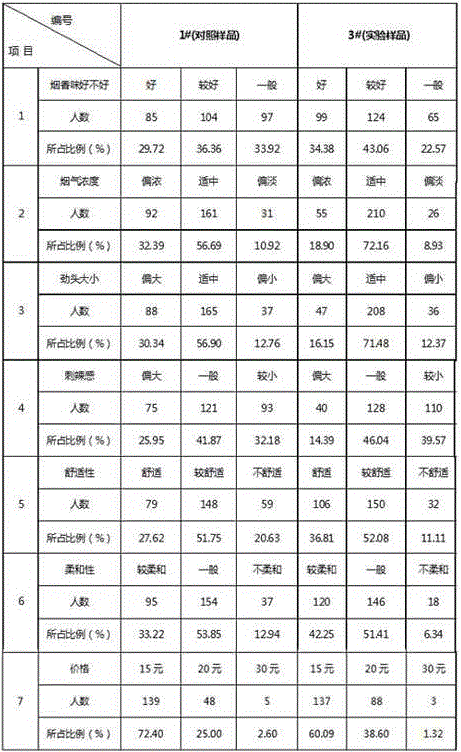

Examples

preparation example Construction

[0024] The tobacco raw material concentrate is prepared by the following steps:

[0025] Put the minced tobacco leaves and tobacco stems into the soaking tank at a mass ratio of 1:1, soak at a temperature of 30-80°C for 0.5-2 hours, squeeze and filter to obtain a tobacco aqueous solution, and the obtained tobacco aqueous solution is at -0.09- Vacuum concentration at a vacuum degree of 0 MPa and a temperature of 50-100°C, until the mass percentage of solids in the concentrated liquid reaches 35%-50%, to obtain a concentrated tobacco raw material liquid, which can be directly coated on the tobacco sheet basically.

[0026] The main components of the extract of Rhizoma Imperatae are rich in potassium salt, a large amount of glucose, sucrose and a small amount of fructose, xylose; simple acids: citric acid, malic acid. Rich potassium salts are used to improve the combustibility; glucose, malic acid are used to alcoholize and concentrate the extract, and then carry out Maillard re...

Embodiment 1

[0028] Step 1: Cut the Imperata Rhizome into sections and thick slices, immerse it in cold water for 30 minutes according to the mass ratio of 1:8, boil the water for 30 minutes, filter to obtain the crude extract of Imperata Rhizoma Imperatae, and filter the Immerse in cold water again, and repeat the above steps three times continuously to obtain the final crude extract of Imperata rhizome.

[0029] Step 2: Treat the final crude extract of Imperata Rhizome obtained in Step 1 by alcohol extraction and water precipitation method to obtain fine extract of Imperata Rhizome.

[0030] Step 3: When producing reconstituted tobacco leaves by the papermaking method, mix the extract of Rhizoma Imperatae, tobacco aroma module, and concentrated tobacco raw material in a mass ratio of 2:1:12 to obtain a coating material liquid, and mix the coating material The liquid is coated on the paper-making substrate to prepare functional reconstituted tobacco leaves by paper-making method.

[0031...

Embodiment 2

[0037] Step 1: Cut the root of Imperatae Rhizoma into sections and thick slices, soak it in cold water for 45 minutes according to the mass ratio of 1:8, boil the water for 30 minutes, filter to obtain the crude extract of Rhizome Imperatae, and filter the Immerse in cold water again, and repeat the above steps three times continuously to obtain the final crude extract of Imperata rhizome.

[0038] Step 2: Treat the final crude extract of Imperata Rhizome obtained in Step 1 by alcohol extraction and water precipitation method to obtain fine extract of Imperata Rhizome.

[0039] Step 3: When producing reconstituted tobacco leaves by the papermaking method, mix the extract of Rhizoma Imperatae, tobacco aroma module, and concentrated tobacco raw material in a mass ratio of 2:1:12 to obtain a coating material liquid, and mix the coating material The liquid is coated on the paper-making substrate to prepare functional reconstituted tobacco leaves by paper-making method.

[0040] i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com