Universal welding device for blocky welding blocks and application method thereof

A welding device and block-shaped technology, applied in welding equipment, aluminothermic welding equipment, metal processing equipment, etc., can solve the problems of inability to use directly, low efficiency, and complicated production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

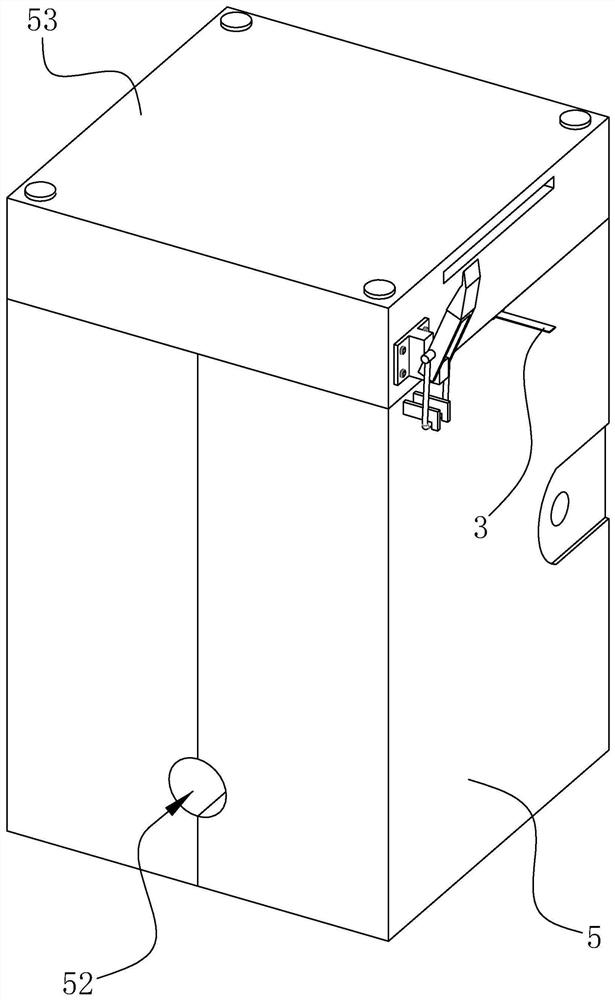

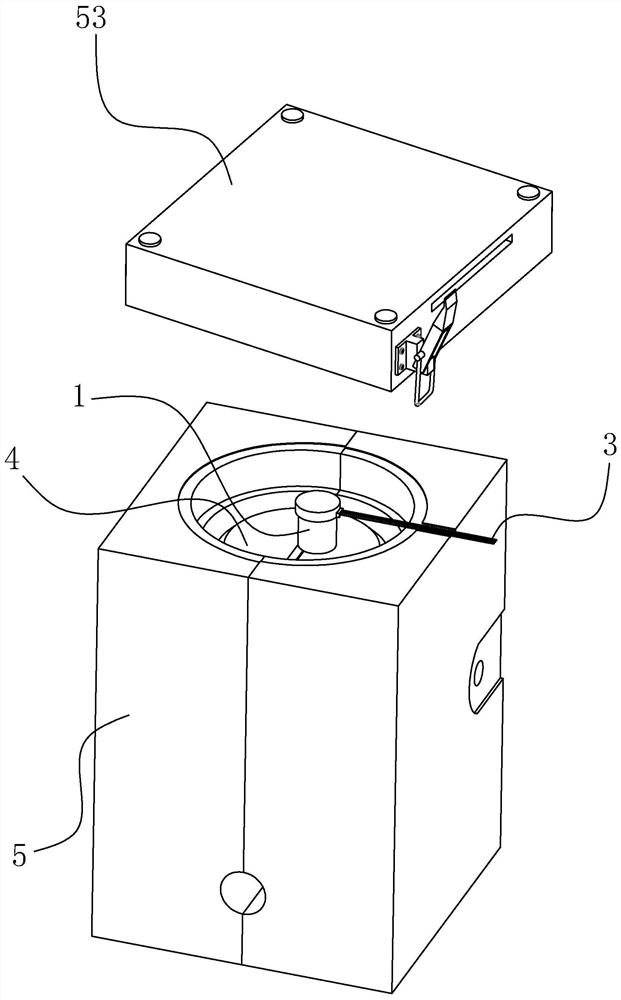

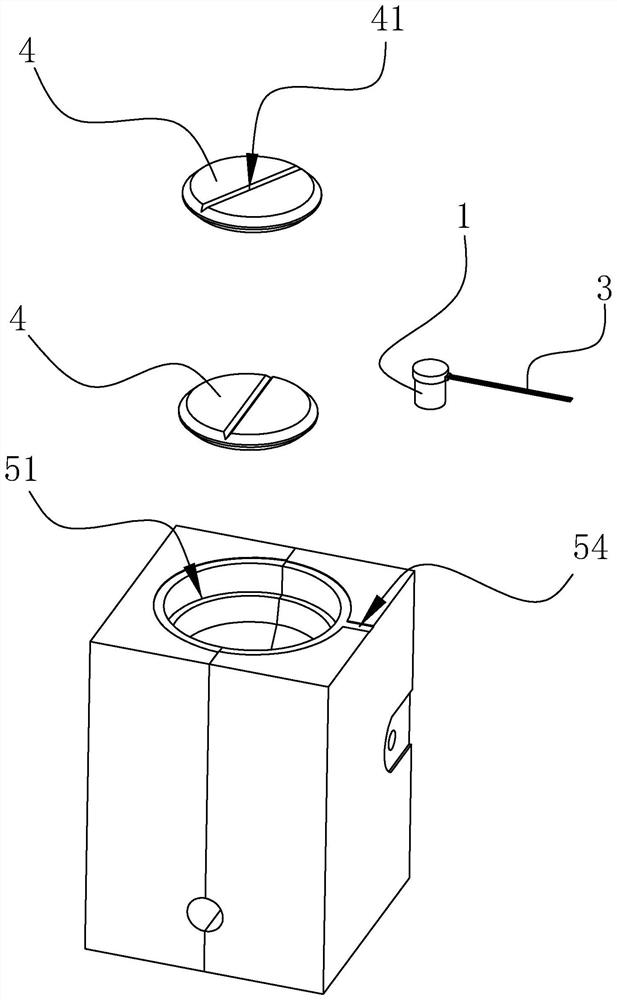

[0042] like Figure 1 to Figure 11 As shown, the device of this embodiment that can be used for welding pipes of various specifications includes a welding mold, which can be placed in the mold cavity 51 of the welding mold and flow into the molding cavity 52 in the welding mold in a hot molten state after being ignited One end can extend into the mold cavity 51 to contact with the solder, and the other end is located outside the mold for ignition strip 3 for ignition. The solder is a block body 4 of uniform specification, and stretches into the mold cavity 51 to contact with the solder. The end of the ignition strip 3 which is in contact with the welding agent is provided with an ignition box, and the ignition box is filled with ignition powder 12, and the end of the ignition strip 3 is inserted into the ignition box to contact with the igniti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com