Laminated wood prestressed sleeve bolt joint and construction method thereof

A bolt joint and prestressing technology, which is applied in construction, building material processing, building construction, etc., can solve the problems of large section weakening, circular casing wedge effect, wood splitting along the grain, etc., and achieve the integrity of the column section , Delay wood splitting, delay the effect of splitting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

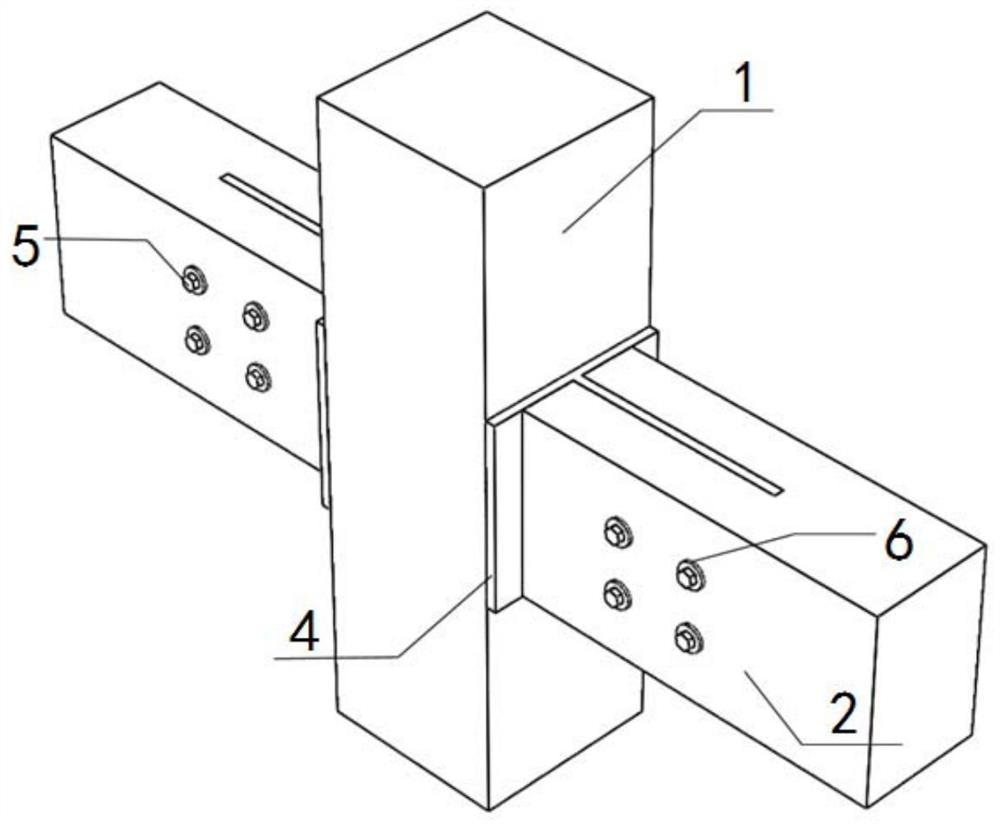

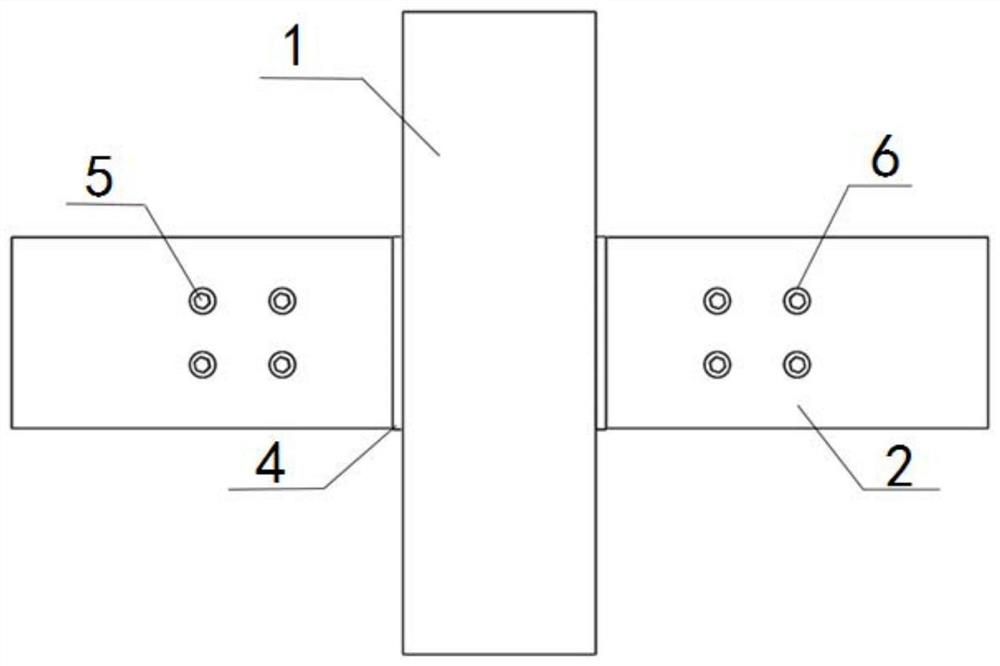

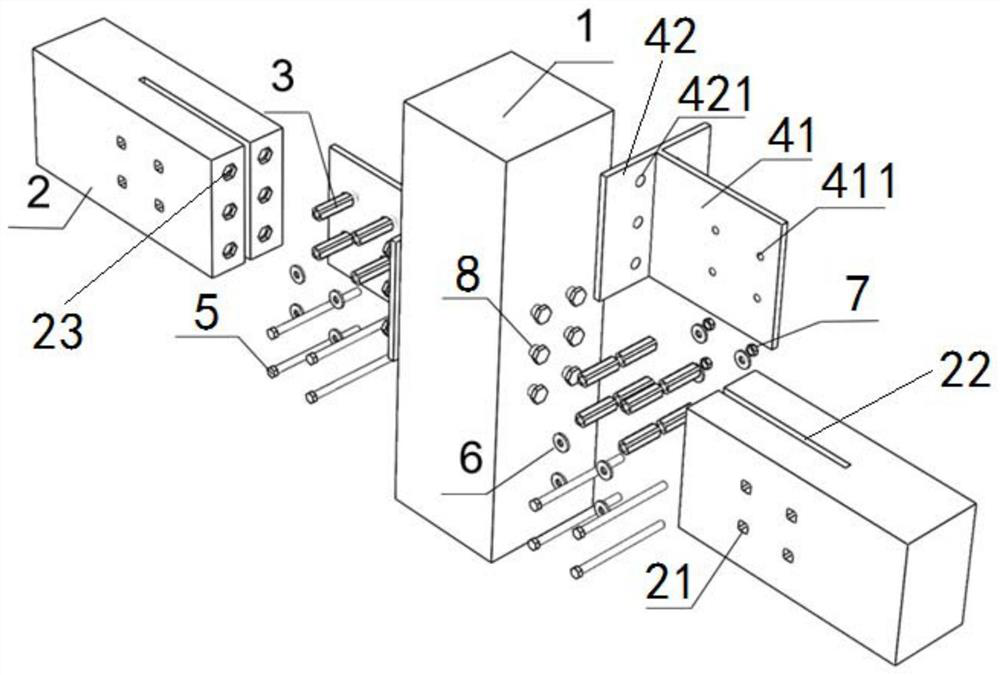

[0039] A glulam prestressed casing bolt joint based on planted studs, including a wooden column 1 made of laminated glulam, a wooden beam 2 made of laminated glulam, an inner circle and an outer square casing 3, and a T-shaped steel splint 4. High-strength bolts 5, gaskets 6, nuts 7 and chemical slurry anchor bolts 8, T-shaped steel splints 4 and wooden columns 1 are connected by the stud planting method. The T-shaped steel splint 4 is connected to both sides of the wooden column 1 through the chemical slurry anchor bolt 8. The wooden column 1 is provided with a second bolt reserved hole 11 corresponding to the chemical slurry anchor bolt 8, so that the chemical slurry anchor bolt 8 passes through the T-shaped steel. The third bolt reserved hole 421 and the second bolt reserved hole 11 on the wing plate 42 of the splint 4 penetrate into the wooden column 1 and tightened. The T-shaped steel splint 4 and the wooden beam 2 are connected by an inner circle outer square casing 3 an...

Embodiment 2

[0042] A glued wood prestressed casing bolt joint based on planted studs. The wooden beam 2 is prefabricated in the factory and cuts a groove 22 and drills a quadrilateral hole 21 according to the wood processing method. The depth of the groove 22 is deeper than that of the T-shaped steel splint 4 web 41 Length is slightly longer. The inner circle outer square casing 3 is made by casting in the factory, and it should be closely combined with the quadrilateral hole 21. The side length of the casing is smaller than the hole side length, but the error is less than 0.5mm. During specific installation, the plywood glulam beam 2 is encased in the T-shaped steel splint 4 from top to bottom, and then the inner circle and the outer square casing 3 are coated with structural glue and pressed into the quadrilateral hole 21. After the structural glue has a certain strength, the The high-strength bolt 5 penetrates the inner circle outer square casing 3 and passes through the first bolt res...

Embodiment 3

[0045] A glued wood prestressed casing bolt joint based on planted studs. A bolt end receiving groove 23 is provided at the end of the connection side between the wooden beam 2 and the T-shaped steel splint 4 to ensure that the T-shaped steel splint 4 and the wooden beam 2 are connected. The end of the beam 2 can be close to the wing plate 42 of the T-shaped steel splint 4, further improving the connection strength and stability of the wooden beam 2 and the T-shaped steel splint 4, and the rest of the structure is the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com