A multi-stage energy dissipation device for earthquake resistance and vibration reduction of building structures

A technology for building structures and energy-consuming devices, applied in building components, buildings, building types, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

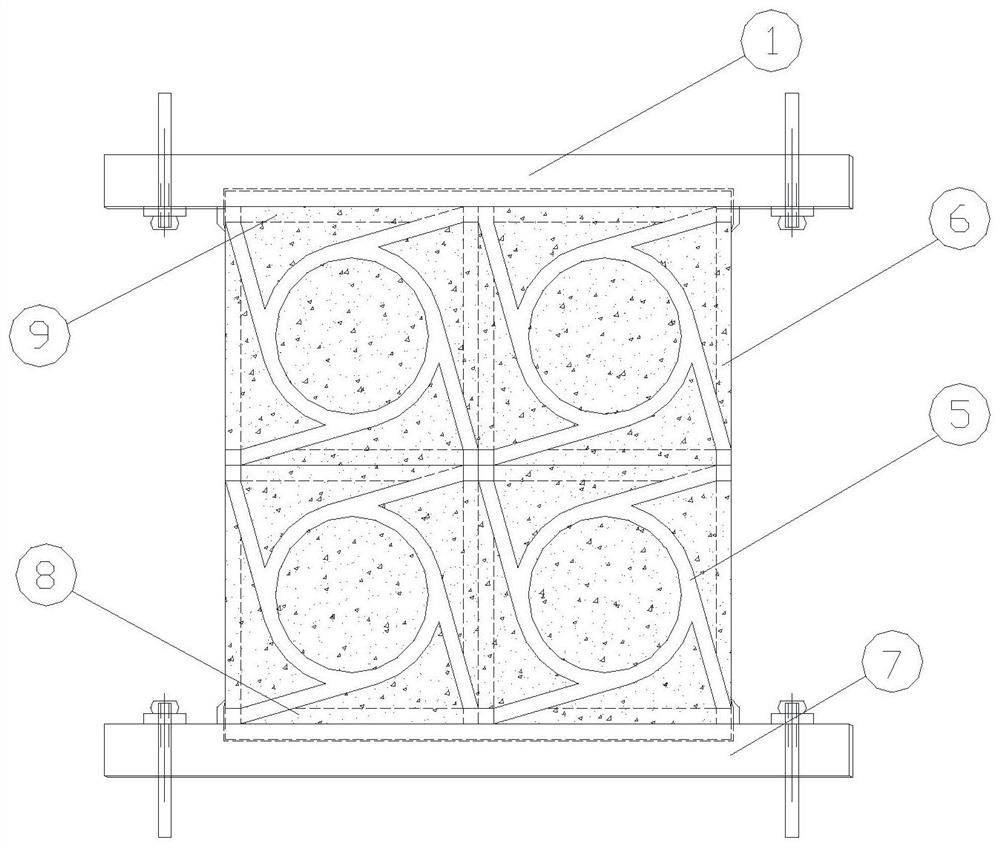

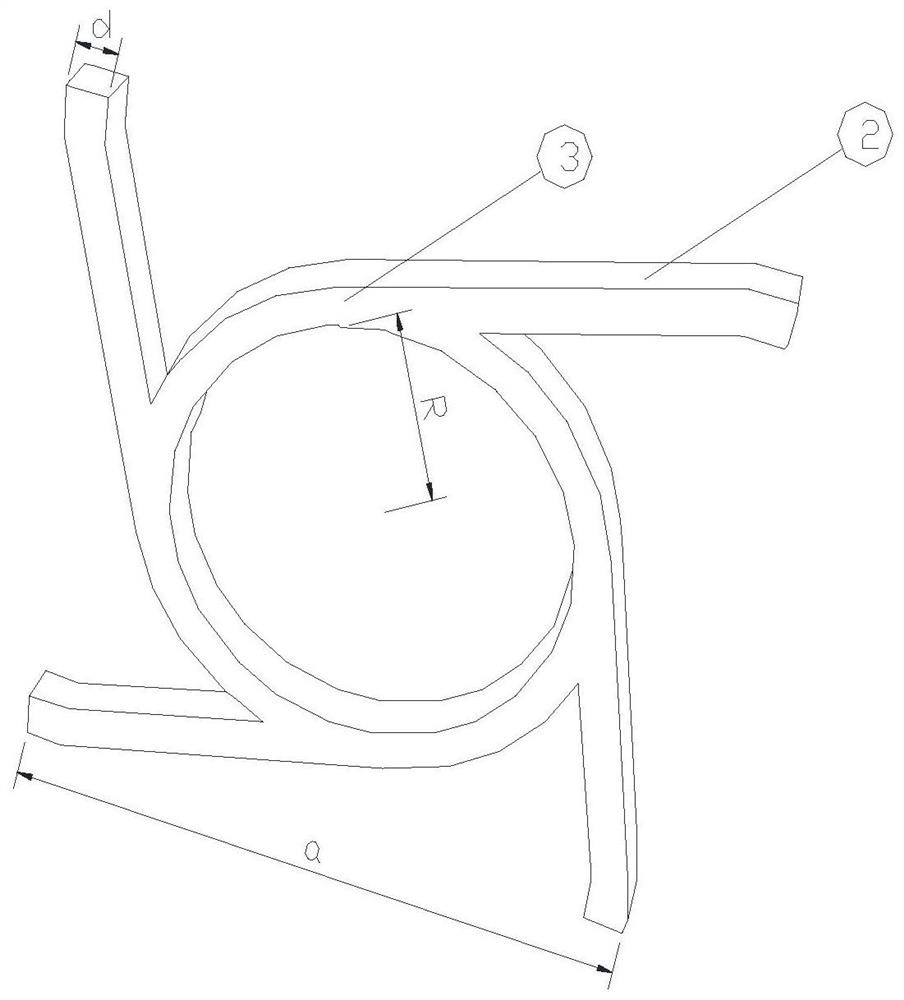

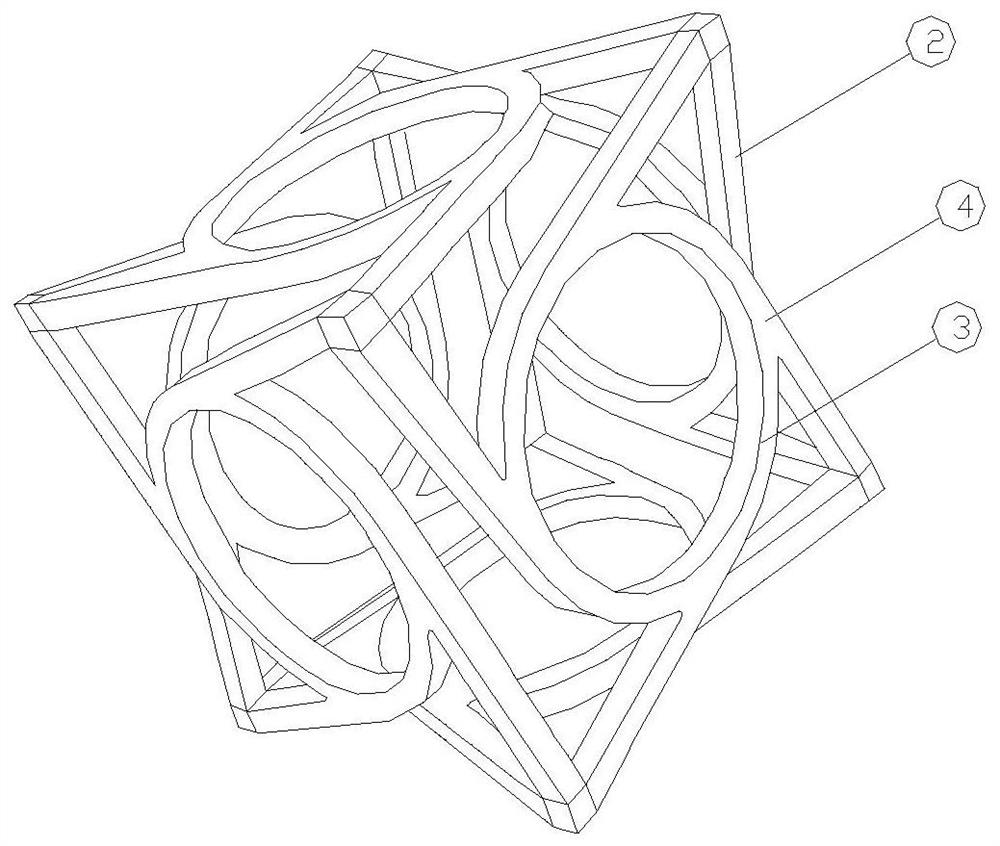

[0023] Such as figure 1 , 2 , shown in 3 and 4, a multi-stage energy dissipation device for anti-seismic and vibration reduction of a building structure, including a base (7), a skeleton unit (5) and a support plate (1), is characterized in that: a plurality of said skeleton units (5) form a steel skeleton, the lower part of the steel skeleton is provided with a base (7), the skeleton unit (5) is composed of six plates (4) of the same form, and the inside of the plate is a ring (3), Four equal support rods (2) protrude tangentially at equal intervals from the outside, the inside of the skeleton unit (5) is filled with high damping rubber (6), and a support plate (1) is arranged on the upper part of the steel skeleton.

[0024] The upper surface of the base (7) is provided with an upper groove (8), the steel frame is placed in the upper groove (8), and the base (7) is welded under the steel frame.

[0025] The lower surface of the support plate (1) is provided with a lower gr...

Embodiment 2

[0033] Rigidity adjustment and programming control can be realized by adjusting the internal and external radius and thickness of the inner ring (3) of the plate (4), the size of the included angle of the support rod (2) and the number of skeleton units (5).

[0034] When the outer steel skeleton is subjected to axial pressure, the skeleton unit (5) will be torsionally deformed, reflecting the compression-torsion coupling effect. Such as Figure 5 , 6 As shown, the stiffness of the system is designed by adjusting parameters such as the radius, width, and unit cell size of the ring to achieve controllable stiffness.

[0035] The data simulation analysis of the energy-consuming device is carried out. Due to the periodic characteristics of the system, a skeleton unit (5) of the device is used for pseudo-static numerical analysis. The lower part of the skeleton unit (5) is fixed, and the axial cyclic displacement is applied to the upper part of the skeleton unit (5) through disp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com