Smelting device

A technology for smelting furnaces and connecting pipes, which is applied in the field of smelters. It can solve the problems of poor cooling effect of the water jacket, burn-through and leakage of the water jacket of the feeding pipe, and achieve the effect of protecting the feeding pipe and prolonging the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

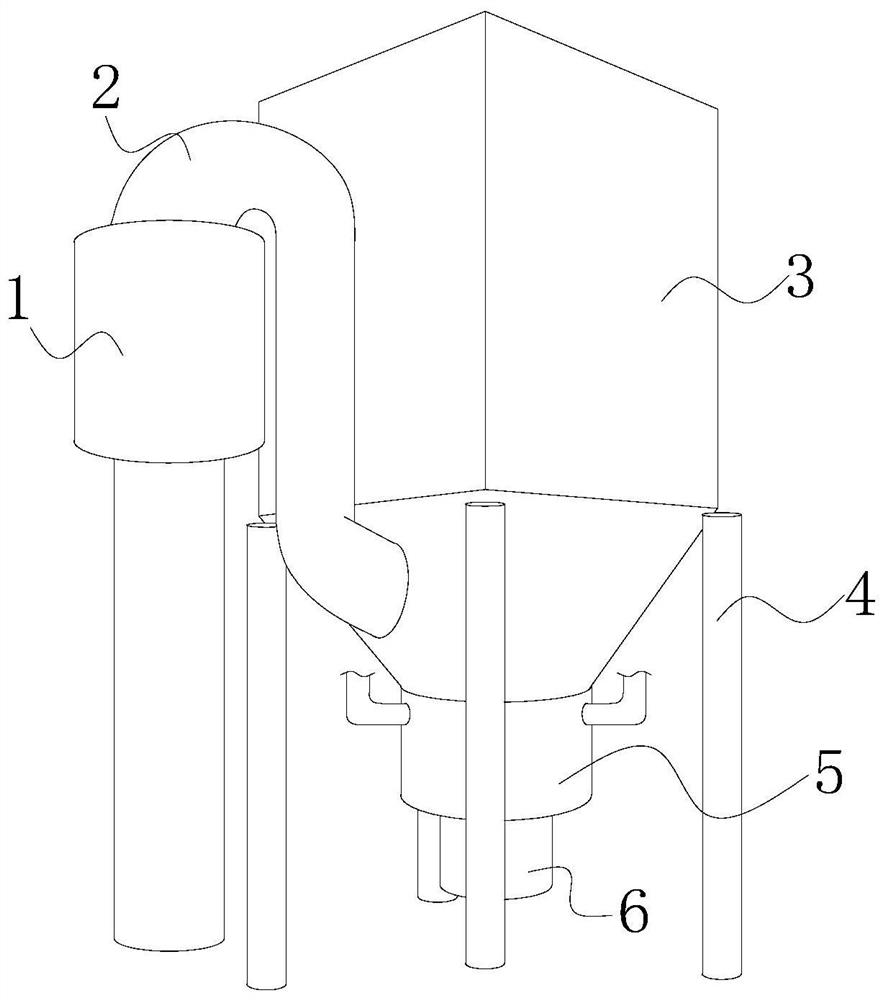

[0024] see Figure 1-Figure 5 , the present invention provides a smelter whose structure includes an exhaust chamber 1, a connecting pipe 2, a smelting furnace 3, a support column 4, a connecting end 5, and a feeding pipe 6, and the exhaust chamber 1 is connected with the connecting pipe 2. , the other end of the connecting pipe 2 is communicated with the melting furnace 3, the bottom of the melting furnace 3 is provided with a support column 4, the support column 4 is mechanically welded with the melting furnace 3, and the melting furnace 3 is connected to the lower part through the connecting end 5 The feed tube 6 is connected.

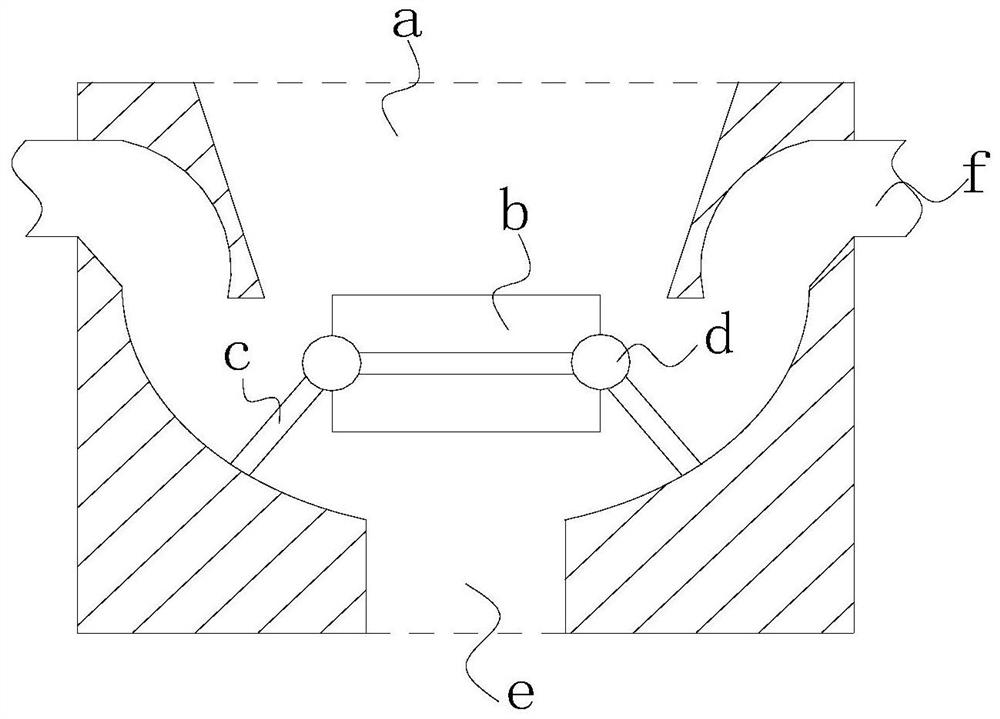

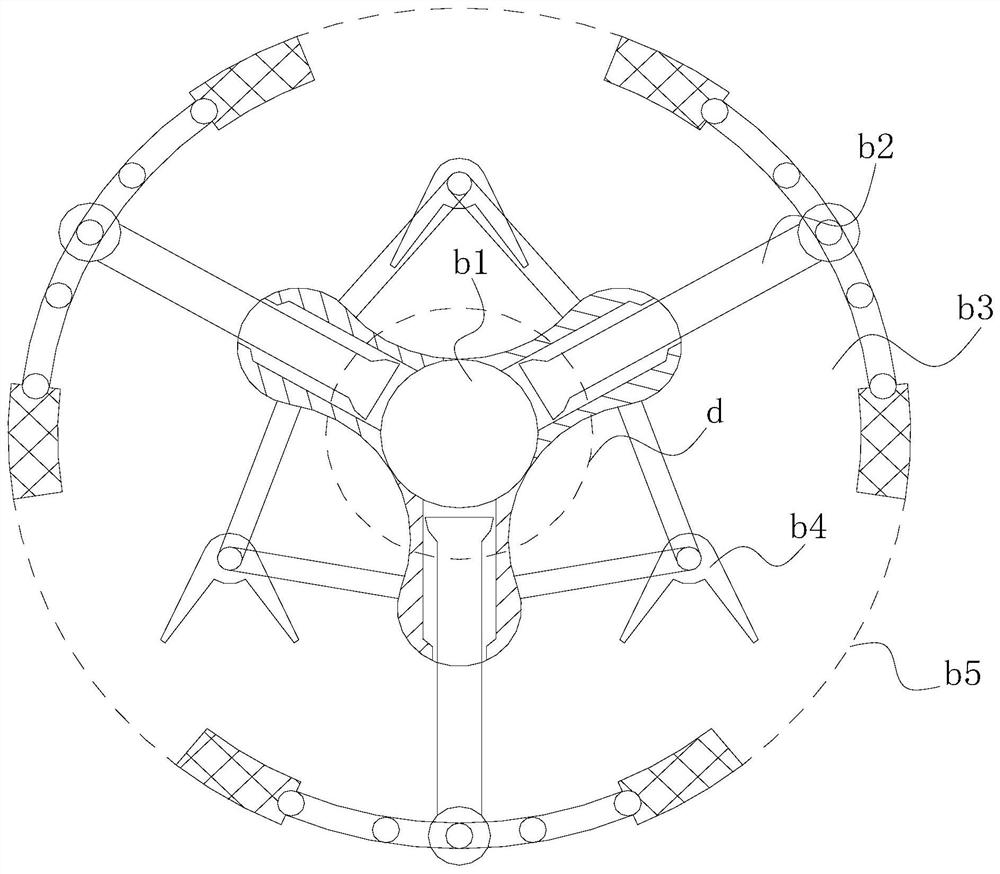

[0025] The connecting end 5 is composed of an inlet end a, a stirring mechanism b, a support rod c, a connecting end d, an output end e, and a guiding pipe f. The inlet end a is communicated with the output end e, and the output end e is connected to the lower end. The feed pipe 6 is communicated, the inlet end a is connected with the melting furna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com