A long-pass filter with multiple nano-pillar arrays

A nano-column array and optical filter technology, which is applied in the direction of optical filters, optics, optical components, etc., can solve the problems of limited application and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further explained below in conjunction with the accompanying drawings.

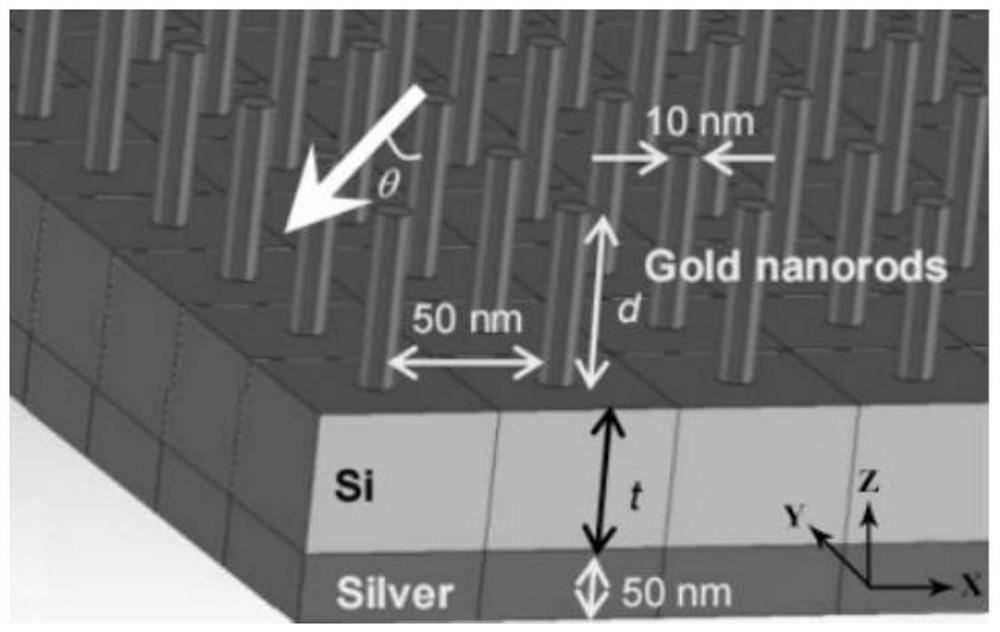

[0037] like Figure 9 to Figure 12 As shown, a multi-nano-pillar array long-pass filter is composed of wavy subwavelength metasurface units arranged in an array, and the wavy subwavelength metasurface unit includes a substrate and a metasurface structure arranged on the substrate. The structure is composed of two rows of "V" type inverted wavy structures and two rows of "Λ" type positive wave structures arranged at equal intervals in order from independent GaAs nano-cylinders.

[0038] Among them, in the "V"-shaped inverted wavy structure, the reference cylinder is located in the middle position, and the GaAs nanocylinders extend along both sides of the x-axis in an arithmetic progression, and extend up along the z-axis; in the "Λ"-shaped positive wavy structure , the reference cylinder is located at both ends, extending in the middle along the x-axis in the same arit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com