Selective infrared absorbing material based on ionic liquid and its preparing process

An ionic liquid and infrared absorption technology, applied in chemical instruments and methods, and other chemical processes, can solve problems such as poor compatibility, and achieve the effects of good fluidity, wide application range, and wide liquid use range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

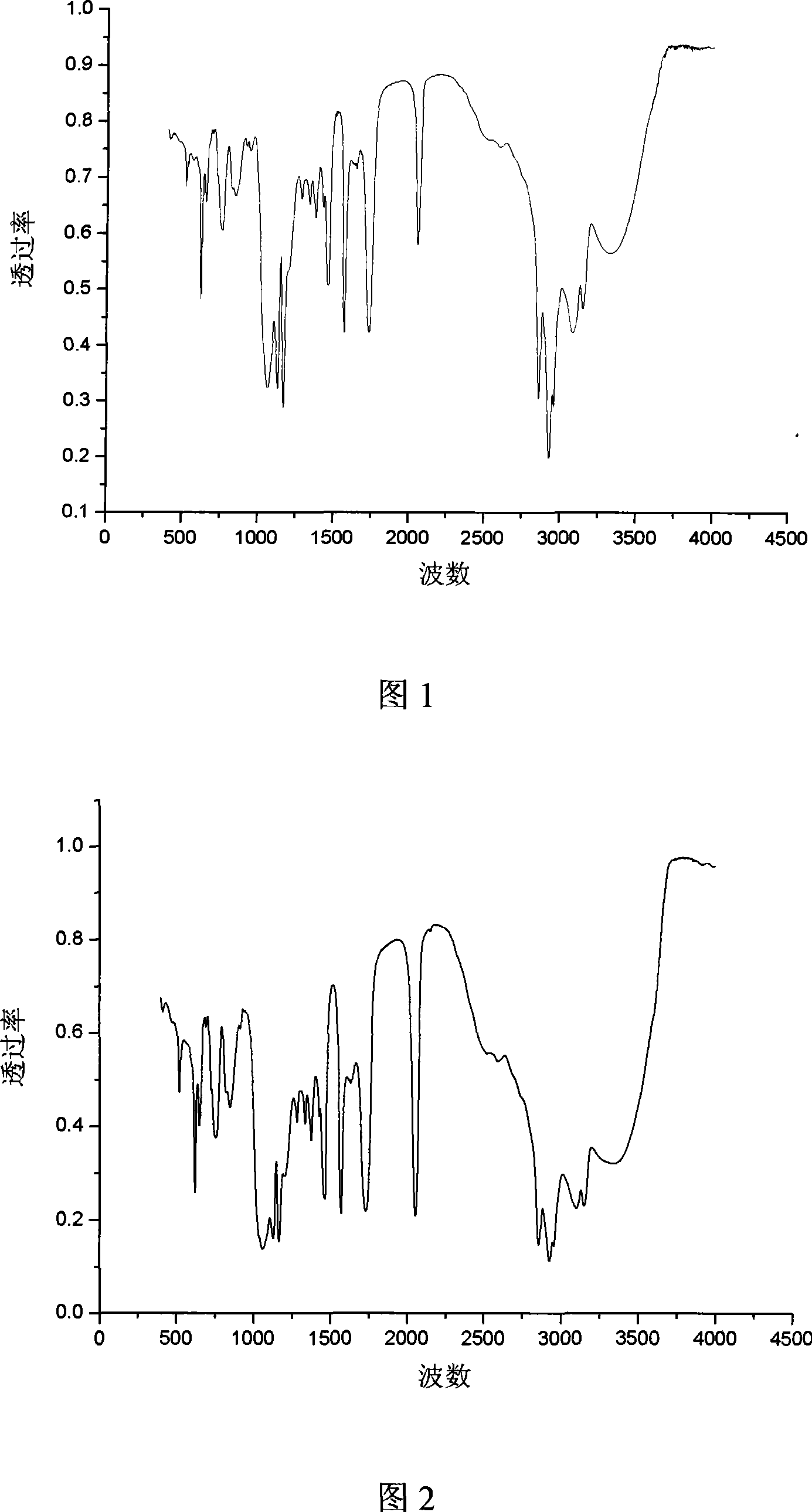

Image

Examples

Embodiment 1

[0030] Example 1 1-methyl-3-octyl imidazolium tetrafluoroborate [C 8 MIm]BF 4 Preparation of ionic liquids

[0031] 22 g BF 4 - The corresponding salt sodium tetrafluoroborate is dissolved in 50 milliliters of cosolvent distilled water, is mixed with the salt solution that mass concentration is 50%, this salt solution is mixed with 46 grams [C 8 MIm]Cl mixed and reacted at 70°C for 5 hours. The mixed solution was cooled and filtered, and the precipitate was filtered to obtain the filtrate. After the filtrate was evaporated to remove the solvent, it was filtered again. The filtrate was extracted with the extractant dichloromethane (3 × 30 ml), the organic phases were combined, and the extractant in the organic phase was evaporated under reduced pressure. , the filtrate was dried with anhydrous sodium sulfate, and finally obtained light yellow transparent [C 8 MIm]BF 4 ionic liquid.

Embodiment 2

[0032] Example 2 1-methyl-3-octylimidazole hexafluorophosphate [C 8 MIm]PF 6 Preparation of ionic liquids

[0033] 22 g PF 6 - The corresponding salt sodium hexafluorophosphate is dissolved in 50 milliliters of cosolvent distilled water, is mixed with the salt solution that mass concentration is 50%, this salt solution is mixed with 46 grams [C 8 MIm]Cl mixed and reacted at 70°C for 24 hours. The mixed solution was cooled and filtered, and the precipitate was filtered to obtain the filtrate. After the filtrate was evaporated to remove the solvent, it was filtered again. The filtrate was extracted with the extractant dichloromethane (3 × 30 ml), the organic phases were combined, and the extractant in the organic phase was evaporated under reduced pressure. , the filtrate was dried with anhydrous sodium sulfate, and finally obtained light yellow transparent [C 8 MIm]PF 6 ionic liquid.

Embodiment 3

[0034] Example 3 1-methyl-3-octyl imidazole thiocyanate [C 8 Preparation of MIm]SCN Ionic Liquid

[0035] 31 g SCN - The corresponding salt potassium rhodanide is dissolved in 50 milliliters of cosolvent acetone, is mixed with the salt solution that mass concentration is 50%, this salt is dissolved in 50 grams [C 8 MIm]Cl mixed and reacted at 60°C for 24 hours. The mixed solution was cooled and filtered, and the precipitate was filtered to obtain the filtrate. After the filtrate was evaporated to remove the solvent, it was filtered again. The filtrate was extracted with the extractant dichloromethane (3 × 30 ml), the organic phases were combined, and the extractant in the organic phase was evaporated under reduced pressure. , the filtrate was dried with anhydrous sodium sulfate, and finally obtained light yellow transparent [C 8 MIm]SCN ionic liquid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com