Automatic tea making machine

A tea making machine and automatic technology, applied in kitchen utensils, household utensils, beverage preparation devices, etc., can solve the problems of lack of sealing of the discharge channel, low efficiency of assembly and replacement, loss of tea aroma, etc., achieve high efficiency and easy operation, improve The efficiency of assembly and replacement and the effect of improving the taste of brewing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The following are specific embodiments of the invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

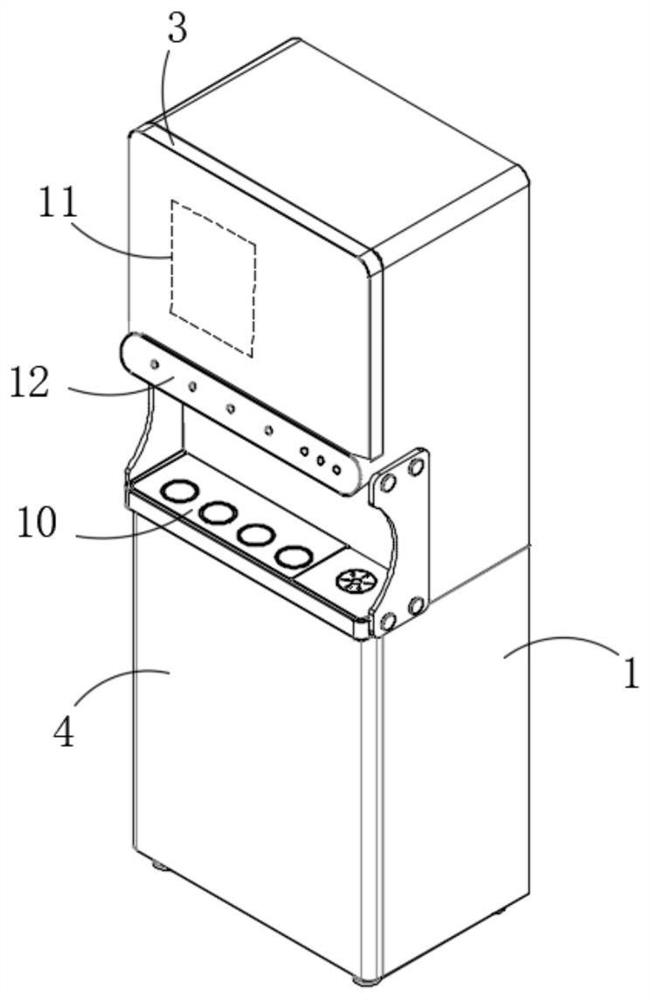

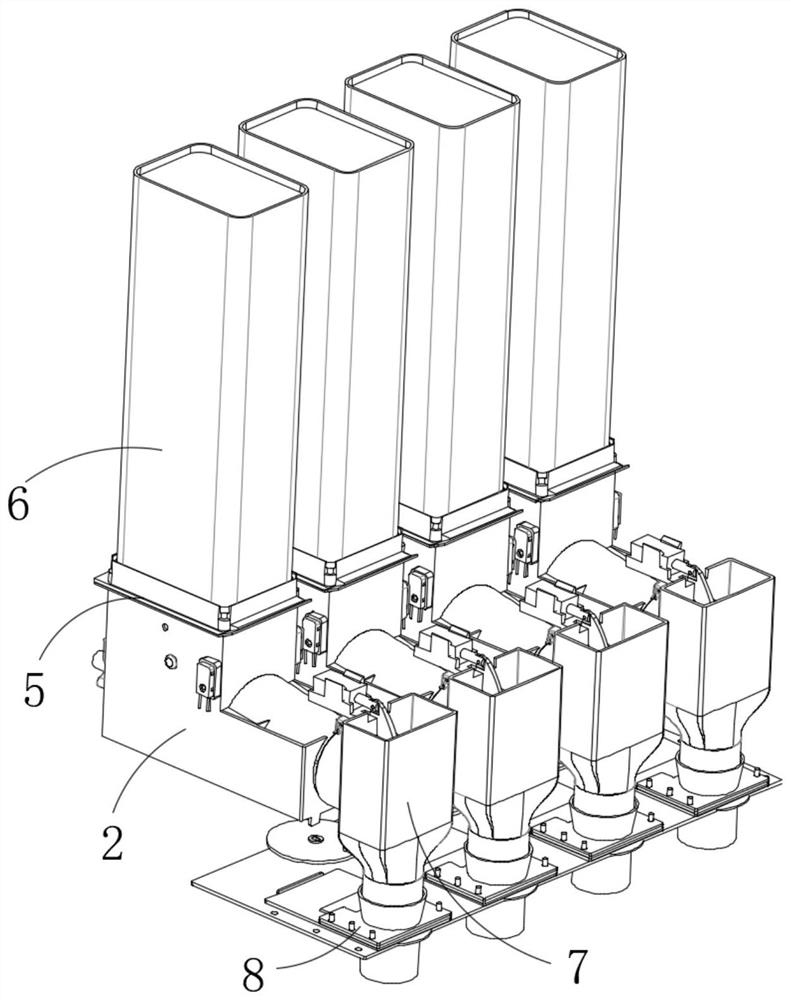

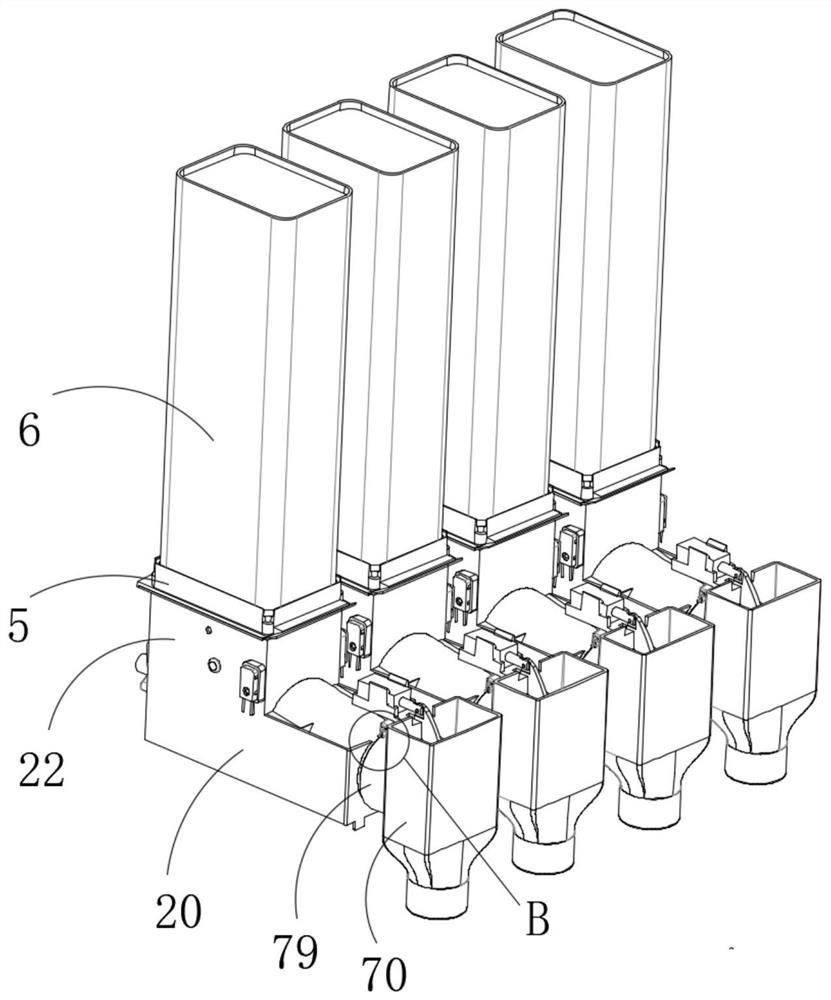

[0066] Such as figure 1 As shown, an automatic tea making machine for original leaf tea includes a cabinet 1, which is provided with a sealed storage device, a discharge mechanism and a discharge sealing mechanism sequentially connected from top to bottom.

[0067] Specifically, the cabinet 1 has an upper chamber and a lower chamber, the upper chamber is used to accommodate the discharge mechanism 2, and the discharge mechanism 2 is used for discharging materials including raw leaf tea leaves, powdered beverage raw materials, etc., and the lower chamber is used for Hold bottled water, and the upper chamber is hinged with an upper door 3 near the human body side, and the lower chamber is hinged with a lower door 4 near the human bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com