Transparent droplet strengthened composite additive manufacturing method

An additive manufacturing and transparent liquid technology, applied in the field of additive manufacturing, can solve the problems of difficult to solve the problem of residual and laying of the constraining layer, and achieve the effect of small size, high universality, and easy manipulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

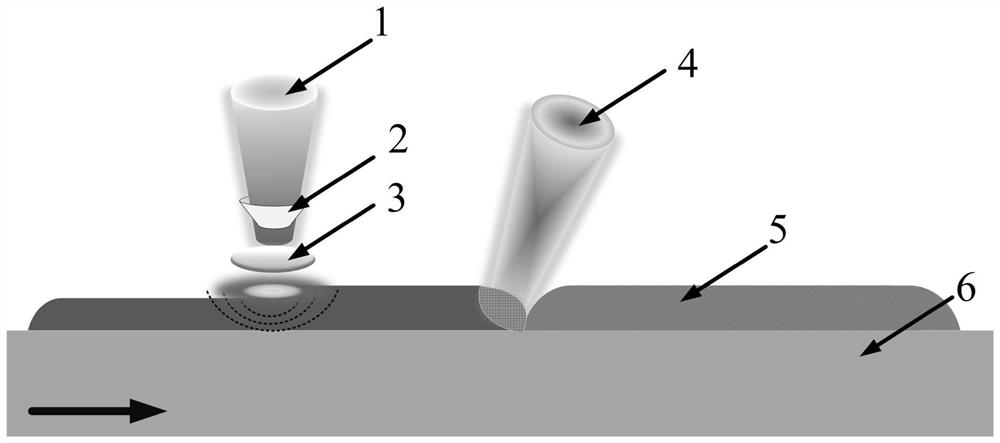

[0024] see figure 1 , the transparent droplet reinforced composite additive manufacturing method of the present invention, the specific steps are as follows:

[0025] (1) Additive manufacturing and temperature laser shock parameter setting. In this example, if figure 1 As shown, the energy of the pulsed laser 1 is 1J, the power of the continuous laser 4 is 700W, the spot diameter of the continuous laser beam is 1mm, the spot diameter of the pulsed laser beam is 1mm, the scanning speed is 4mm / s, and the pulse laser frequency is 5Hz. The thickness of the powder bed 5 is 30 μm, the powder is selected as CoCrFeNi high-entropy alloy, and the base material 6 is 316 stainless steel.

[0026] (2) Setting the initial position and laying frequency of the liquid confinement layer; determine the initial action position of the pulse laser 1 according to the pulse laser indicator light, determine the exit position of the mobile droplet constrained layer generation device 2 according to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com