Green high-strength and high-toughness concrete formula and preparation process thereof

A technology with high strength and toughness and preparation process, which is applied in the field of green high strength and toughness concrete formulation and preparation technology, can solve the problems of inability to automatically process shaped concrete, etc., and achieve the effect of convenience and beauty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

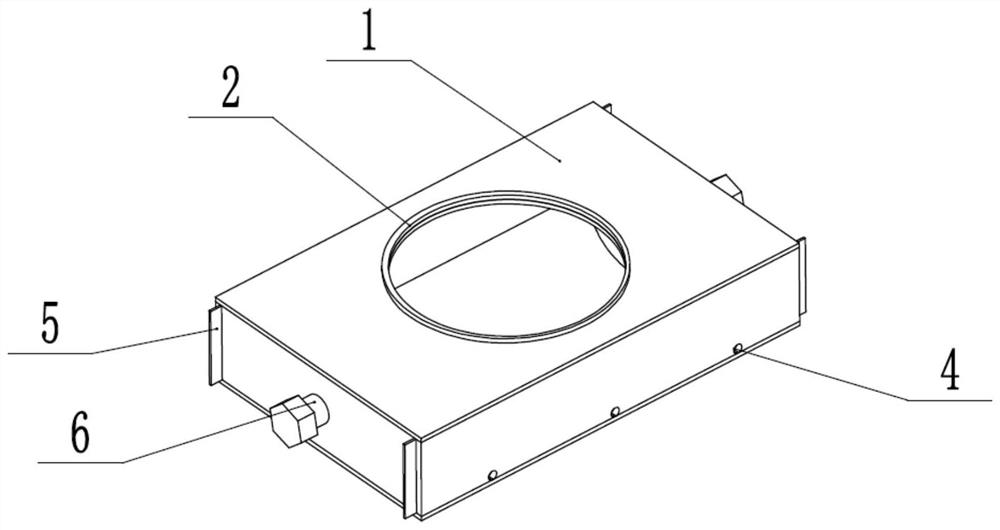

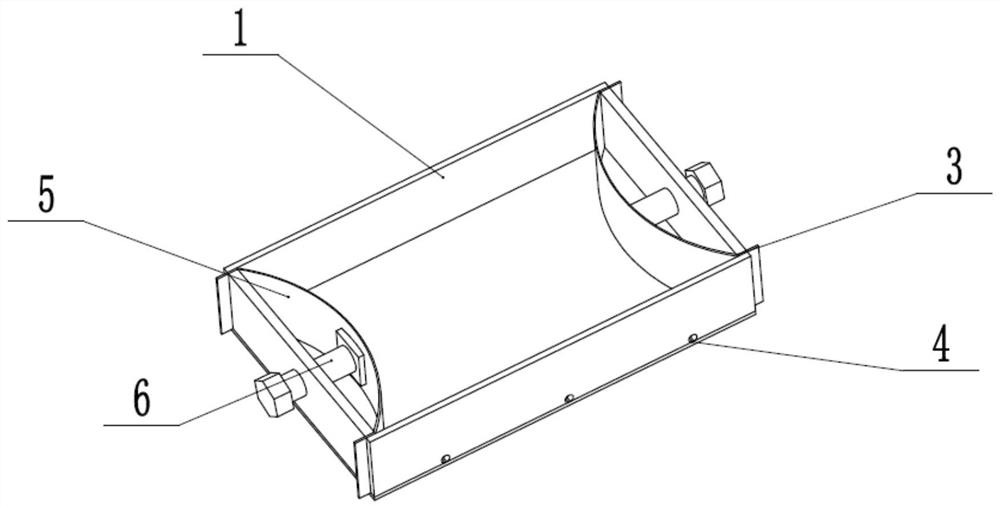

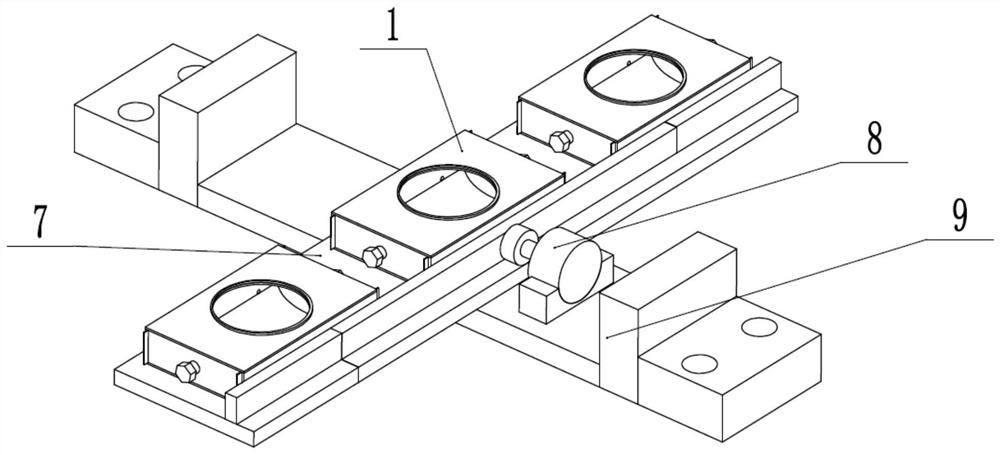

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0032] As shown in the implementation shown here,

[0033] By adding the solid phase and liquid phase raw materials of high-strength concrete into the rotating mixing drum, the rotating mixing drum is driven to rotate, and mixed through the fixed spiral stirring fins, so as to realize the full mixing of the concrete; Drive, so that after the mixed concrete flows out quantitatively, close the switch, and reciprocate in this way to realize quantitative discharge; the discharged concrete falls in the intermittently driven shaping box to realize receiving, close the port, and adjust the two ends of the shaping box by rotating. Squeeze the concrete, drain the excess water, and at the same time realize the processing of concrete blocks with curved sides, which is convenient for the use of concrete and can be realized after condensing the shaping box.

[0034] Furt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com