Intelligent manufacturing stacking industrial robot and stacking method thereof

An industrial robot and intelligent manufacturing technology, which is applied in the stacking of objects, unstacking of objects, transportation and packaging, etc., can solve the problems of prone to smashing, low efficiency of stacking objects, and high labor intensity of manual palletizing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

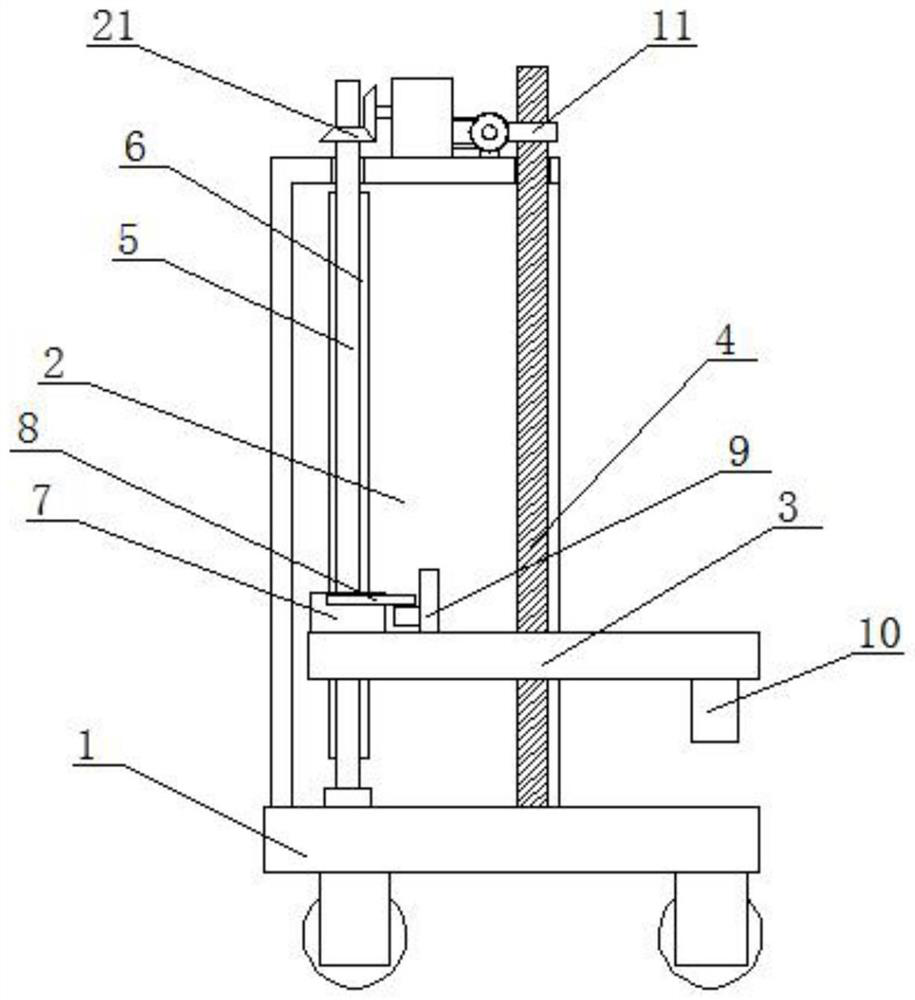

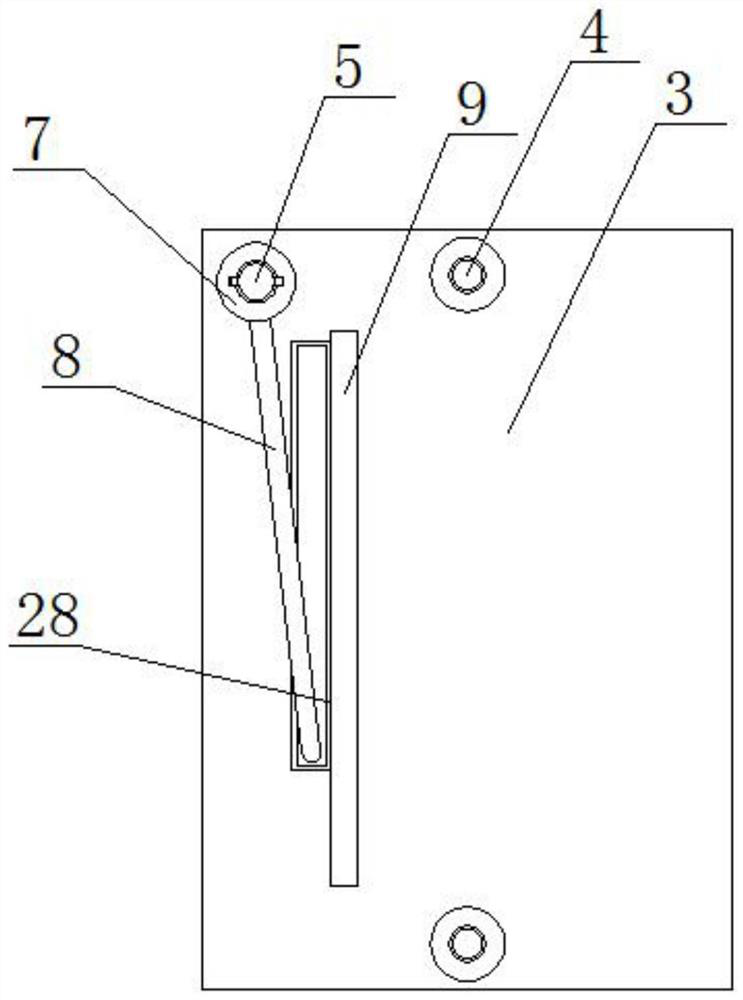

[0030] see Figure 1-5 , this embodiment provides an intelligently manufactured palletizing industrial robot and its palletizing method, including a mobile base 1, a mounting cover 2 is fixedly installed on the top of the mobile base 1, and a lifting plate 3 is slidably connected to the mounting cover 2, Utilizing the lifting plate 3 can facilitate the stable support of the goods, and under the restriction of the inner wall of the installation cover 2, the lifting plate 3 will not shake when it moves longitudinally, and one side of the lifting plate 3 extends to the outside of the installation cover 2 Two lifting screws 4 are symmetrically rotated on the inner wall of the top side of the mounting cover 2, and the bottom ends of the two lifting screws 4 run through the lifting plate 3 and are connected to the top of the mobile base 1 in rotation. The two lifting screws 4 Both are threadedly connected with the lifting plate 3, and the two lifting screws 4 and the lifting plate 3...

Embodiment 2

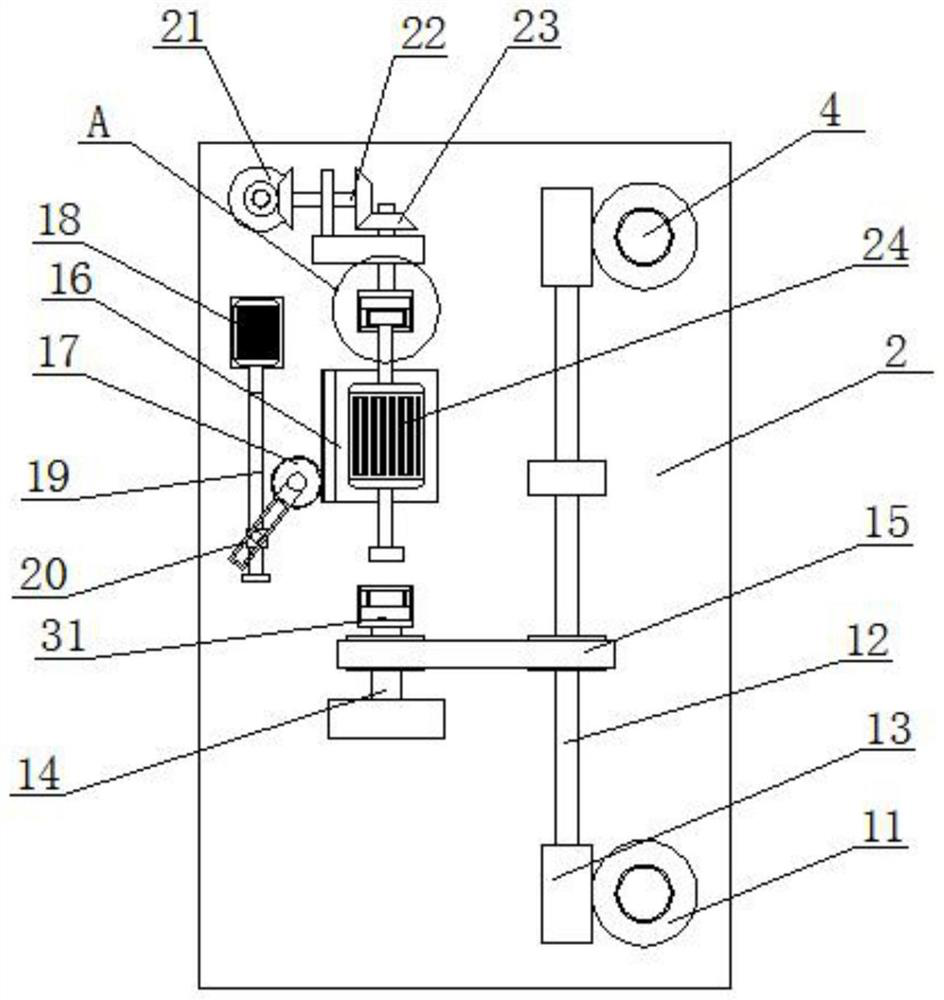

[0034] see Figure 1-5 , further improvements have been made on the basis of Example 1:

[0035] The other side of the top of the installation cover 2 is rotatably connected with a transmission shaft 25, and the transmission shaft 25 has good stability, so when the torque of the biaxial motor 24 is transmitted, no kinetic energy loss will occur, and one end of the transmission shaft 25 is connected to the biaxial The other output shaft of the motor 24 is movably clamped, and the top of the installation cover 2 is rotatably connected to a connecting shaft 22, and one end of the connecting shaft 22 is connected to the transmission shaft 25 in transmission, and the connection shaft 22 is connected to the transmission rod 5 in transmission, and the shaft 22 can be connected It is convenient to stably transmit the torque generated by the biaxial motor 24 to the transmission rod 5 .

[0036] One end of the connecting shaft 22 and the transmission rod 5 are fixedly sleeved with a fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com