Preparation method of cerium dioxidesingle crystal

A single crystal and quartz tube technology, which is applied in the field of preparation of cerium antimonide single crystals, can solve the problems of high residual resistivity, poor crystallinity and small size of single crystals, and achieves high residual resistivity, large crystal size, and high crystallinity. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

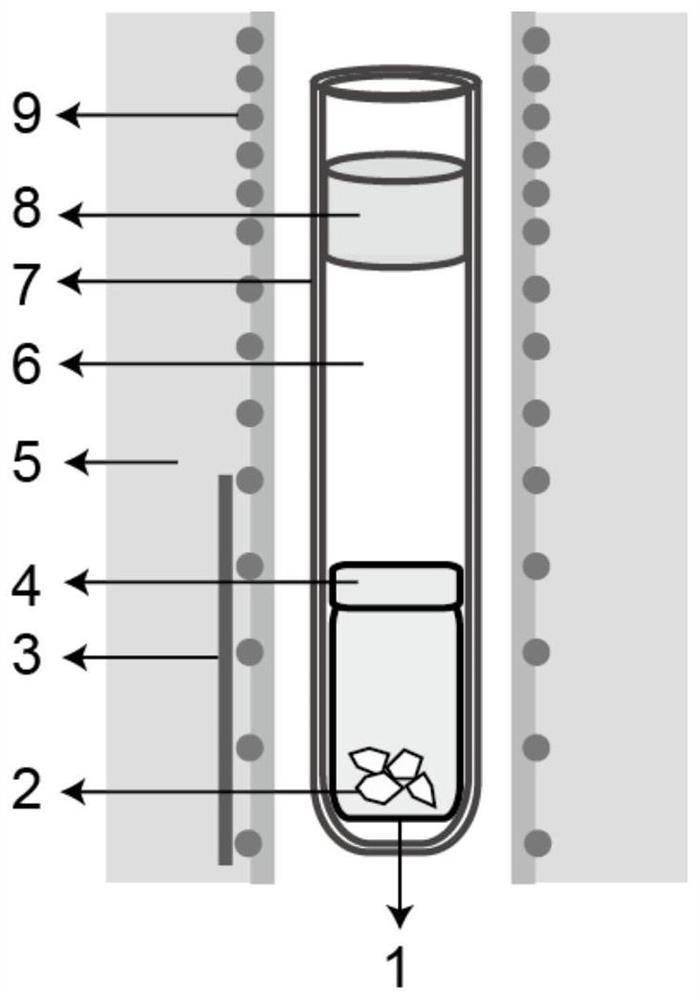

[0037] see figure 1 , figure 1 It is a schematic diagram of the growth device of the cerium antimonide single crystal of the present invention, as can be seen from the figure, the preparation method of the cerium antimonide single crystal of the present invention, the preparation method comprises the following steps:

[0038] 1) Perform standard cleaning on the quartz tube 7, the quartz plug 8, the crucible 1 and the crucible cover 4 to remove surface pollutants, and scrape off the surface pollutants of Ce and Sb blocks (or particles) as reaction raw materials and co-solvents;

[0039]2) Configure Ce and Sb blocks (or particles) 2 as reaction raw materials and cosolvents, and place them in crucible 1 after mixing, wherein the molar ratio of Ce and Sb blocks (or particles) is: n(Ce):n(Sb )=1:11.5;

[0040] 3) Bonding and sealing the crucible cover 4 and the crucible 1 with a high temperature resistant sealant, and placing the sealed crucible 4 at the bottom of the quartz tube...

Embodiment 2

[0049] A method for preparing a cerium antimonide single crystal, the preparation method comprising the following steps:

[0050] 1) Carry out standard cleaning to quartz tube 7, quartz stopper 8, crucible 1 and crucible cover 4, remove surface pollutant, scrape off the surface pollutant of Ce and Sb block (or particle) as reaction raw material and auxiliary solvent, so The material of the crucible and crucible cover is alumina;

[0051] 2) Configure Ce and Sb blocks (or particles) 2 as reaction raw materials and cosolvents, and place them in crucible 1 after mixing, wherein the molar ratio of Ce and Sb blocks (or particles) is: n(Ce):n(Sb )=1:19;

[0052] 3) bonding and sealing the crucible cover 4 and the crucible 1 with a high temperature resistant sealant, and placing the sealed crucible 1 at the bottom of the quartz tube 7;

[0053] 4) Insert the quartz tube 7 loaded into the crucible 1 into the quartz plug 8, and evacuate to a vacuum of 3*10 -3 mbar, keeping the vacuu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com