One-time pouring formwork system and construction method for super-high parapet wall on roof

A formwork system and parapet technology, applied in formwork/formwork/work frame, building, building structure, etc., can solve the problems of poor construction stability, easy to explode form, toppling or collapsing, etc., to meet the requirements of safety, The effect of preventing overturning and improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

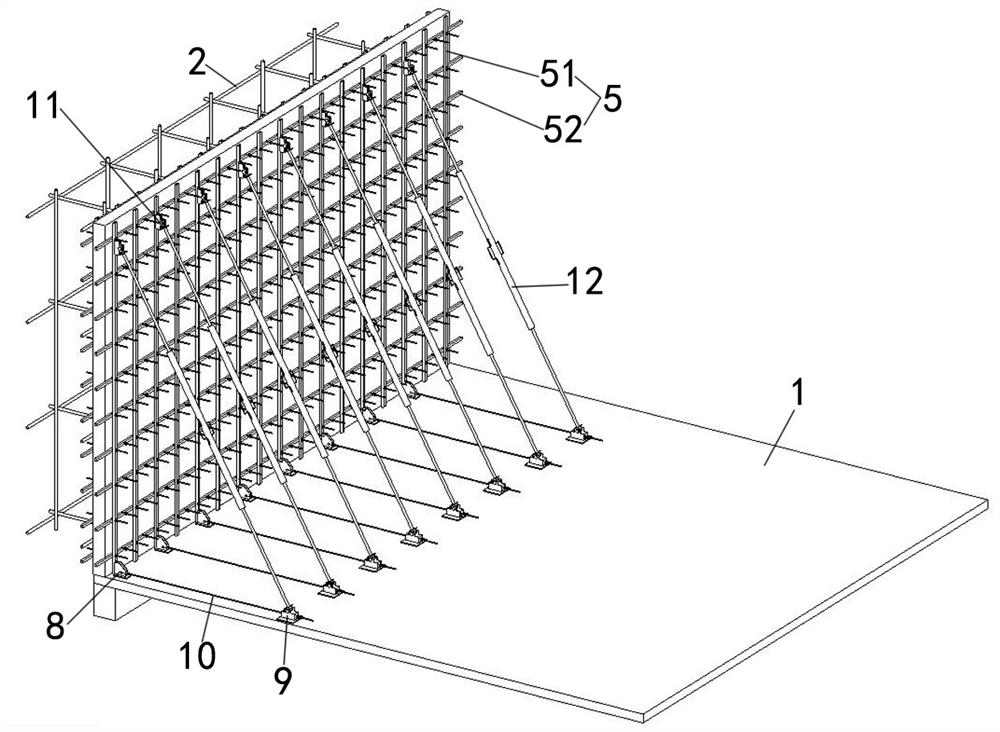

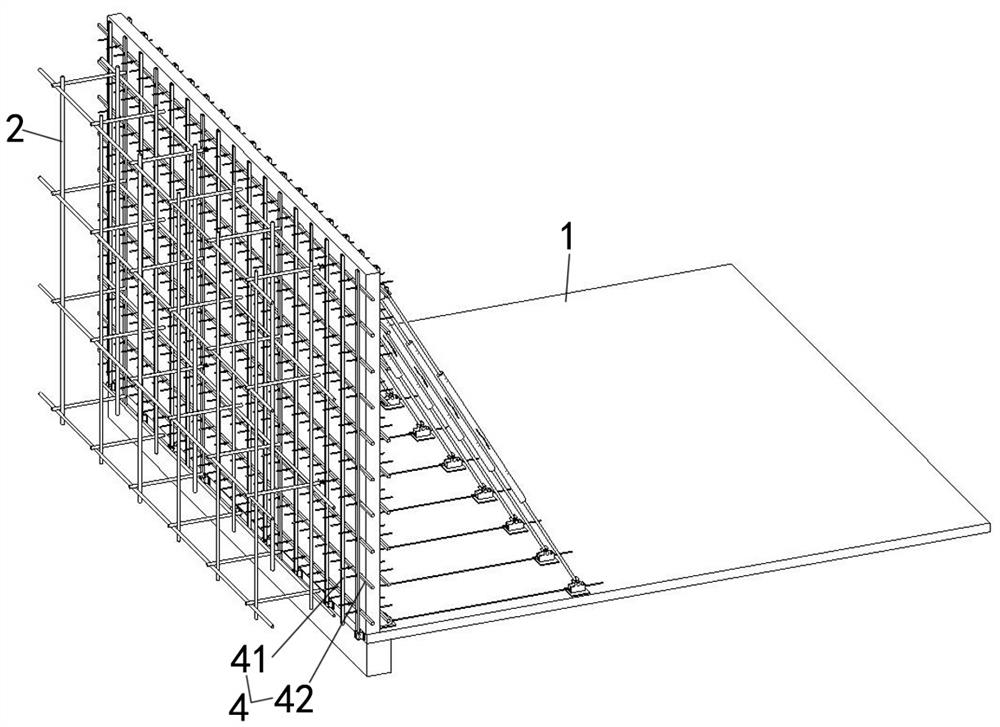

[0063] For this example see Figure 1-2 As shown, a one-time pouring formwork system for a super-high parapet wall on the roof includes a roof panel 1, an external scaffold 2, a parapet formwork system, a set of external scaffold connection wall tie devices, a set of external formwork anti-overturning pre-embedded fixing devices and A set of internal mold explosion-proof stable support device.

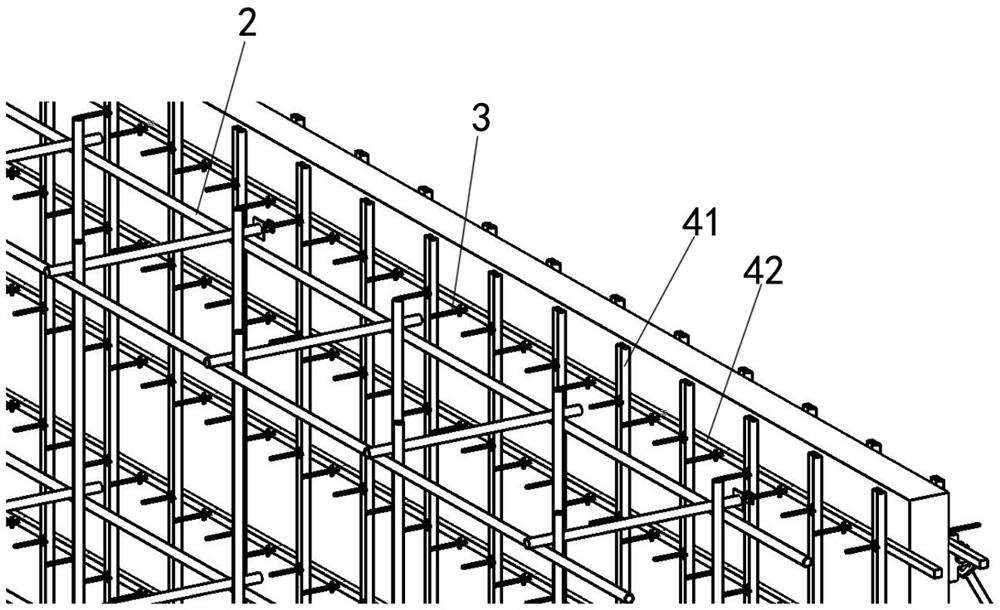

[0064] see Figure 1-2 As shown, the outer scaffolding 2 is located on the outside of the roof panel 1, and the parapet formwork system stands on the outer edge of the roof panel 1, including an outer mold, an inner mold, and a set of tie members for tie-knotting the keels on both sides 3. The outer mold includes an outer mold panel and an outer mold keel 4, the inner mold includes an inner mold panel and an inner mold keel 5, and the outer mold keel includes a set of outer mold main keels 41 and a set of outer mold secondary keels 42. The inner mold joists include a set of inner mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com