Breathing type shield scraper with wear-resisting function

A scraper and shield technology, which is applied in mining equipment, earthwork drilling, tunnels, etc., can solve the problems of high cost, high humidity, and increased cost of shield machines, and achieve the effect of increasing the liquid output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

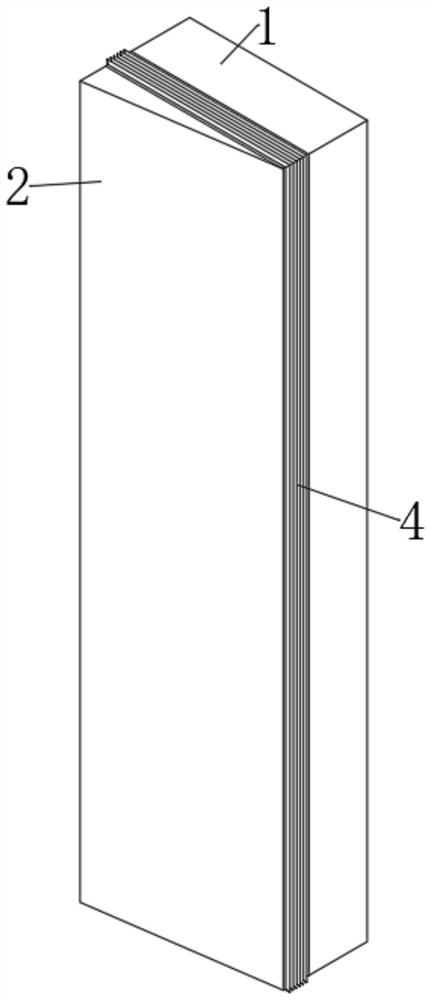

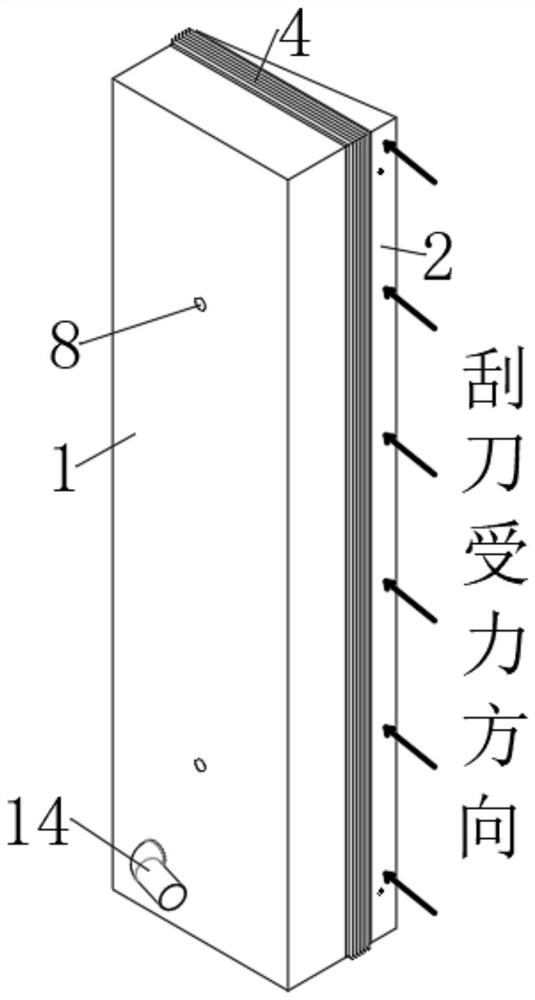

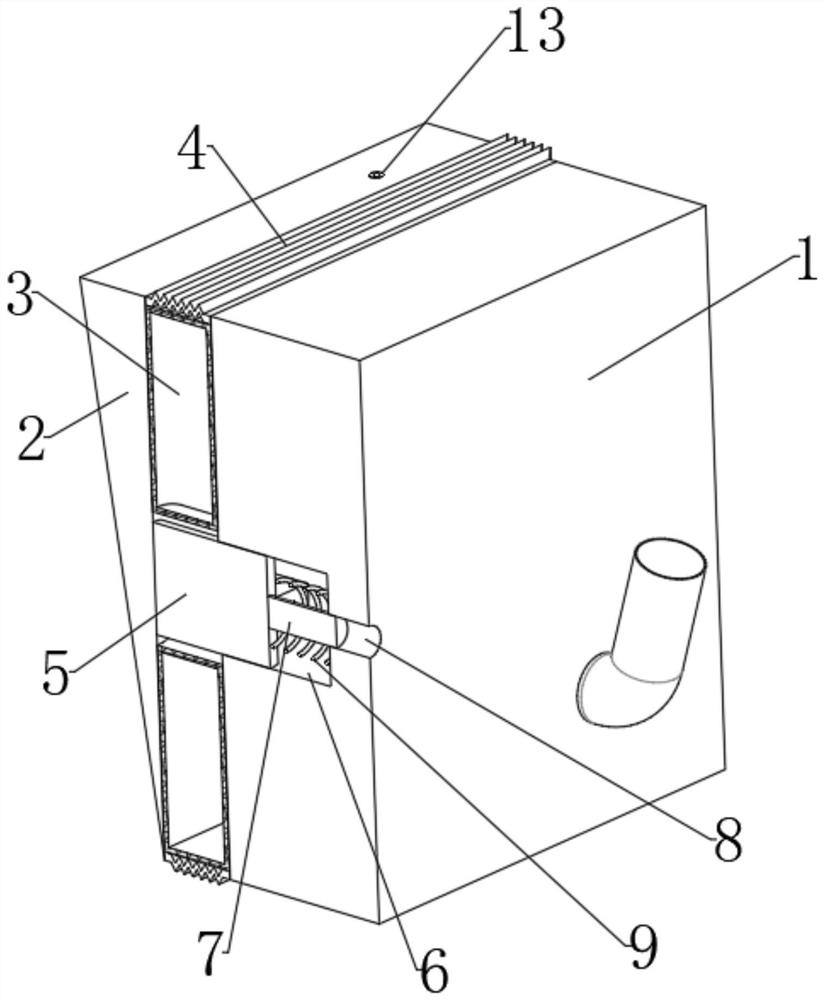

[0038] see figure 1 and Figure 2-8 , a scraper for breathing shield with wear-resistant function, including a base 1 and a working part 2 that match each other, a breathing bag 3 is fixedly connected between the base 1 and the working part 2, and the breathing bag 3 includes an elastic rubber shell 301, elastic A solution chamber 302 is excavated in the rubber shell 301, a pair of connecting rods 5 are fixedly connected to the working part 2, a pair of connecting grooves 6 matching the connecting rods 5 are dug on the base 1, and the groove bottom plate of the connecting rod 5 and the connecting groove 6 A compression spring 9 is fixedly connected between them, a feeding port is dug in the base 1, and a feeding pipe 14 matching itself is fixedly connected in the feeding port, and the end of the feeding pipe 14 close to the base 1 runs through the elastic rubber shell 301 and is connected with the solution The cavities 302 communicate with each other, and the feeding pipeline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com