Permanent magnet synchronous servo submersible motor with extremely low rotating speed and method

A permanent magnet synchronous, submersible motor technology, applied in the direction of magnetic circuit, electrical components, electromechanical devices, etc., can solve the problems of screw pump starting difficulty, large starting torque, low rated speed, etc., to achieve large starting torque, easy starting, Effect of low rated speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

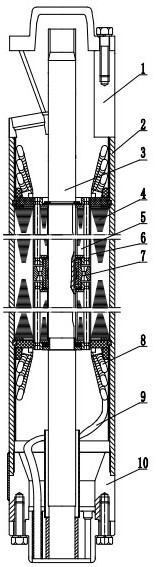

[0021] Embodiment 1, an extremely low-speed permanent magnet synchronous servo submersible motor mentioned in the present invention includes a motor head 1, a motor housing 2, a long motor shaft 3, a motor stator assembly 4, a motor rotor 5, a permanent Magnetic steel 6, rotor righting bearing 7, sensor signal line 9, motor base 10, the upper end of the motor housing 2 is the motor head 1, the lower end is the motor base 10, the motor stator assembly 4 and the motor stator assembly 4 are installed in the motor housing 2 The long motor shaft 3, the motor stator assembly 4 is composed of electromagnetic wire 8 and the motor stator; the long motor shaft 3 is equipped with several motor rotors 5, and the motor rotor 5 is pasted with permanent magnetic steel 6, and each motor rotor The rotor centering bearing 7 is installed between them, and the sensor signal line 9 is led out from the star point at the lower end of the motor housing 2, and connected through the reserved hole of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com