Vacuum tube

A vacuum tube and vacuum heat insulation technology, which is applied in the field of vacuum tubes, can solve the problems of increased diameter, increased material and production costs, and bulkiness of vacuum tubes, and achieve the effects of shortening length, reducing production costs, and reducing body shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

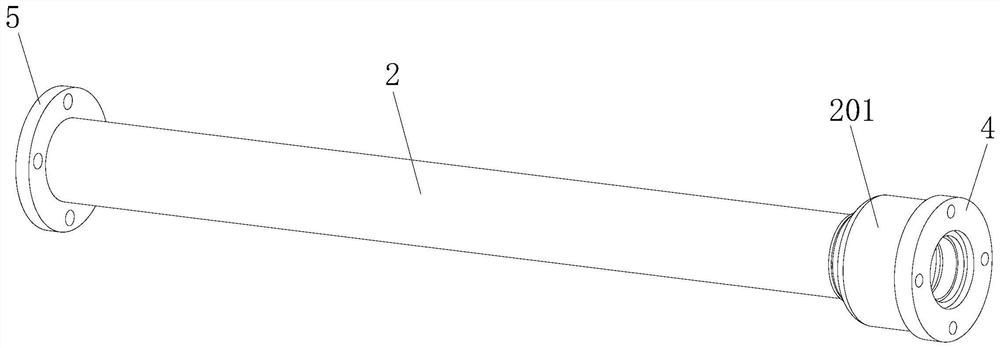

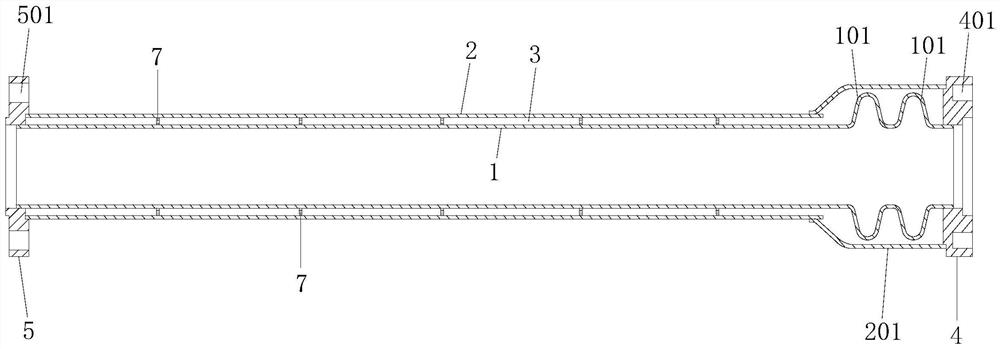

[0057] Figure 1 to Figure 4 A first embodiment of the vacuum tube of the present application is shown, which has a first end and a second end oppositely arranged in its length direction, wherein the first end is figure 2 The right end of the medium vacuum tube, the second end is figure 2 The left end of the medium vacuum tube. The vacuum tube includes an inner tube 1, an outer tube 2, and a vacuum insulation chamber 3 formed between the inner tube and the outer tube. The inner tube 1 has a third end at the aforementioned first end and a fourth end at the aforementioned second end. The outer tube 2 is arranged on the periphery of the inner tube 1, and has a fifth end located at the aforementioned first end and a sixth end located at the aforementioned second end. In this embodiment, the aforementioned third end of the inner tube 1 is figure 2 The right end of the middle inner tube, the aforementioned fourth end of the inner tube 1 is also figure 2 The left end of the ...

Embodiment 2

[0077] Figure 6 The second embodiment of the vacuum tube of the present application is shown, which has basically the same structure as that of the first embodiment, the only difference being that the second embodiment only has one first ring 102 .

Embodiment 3

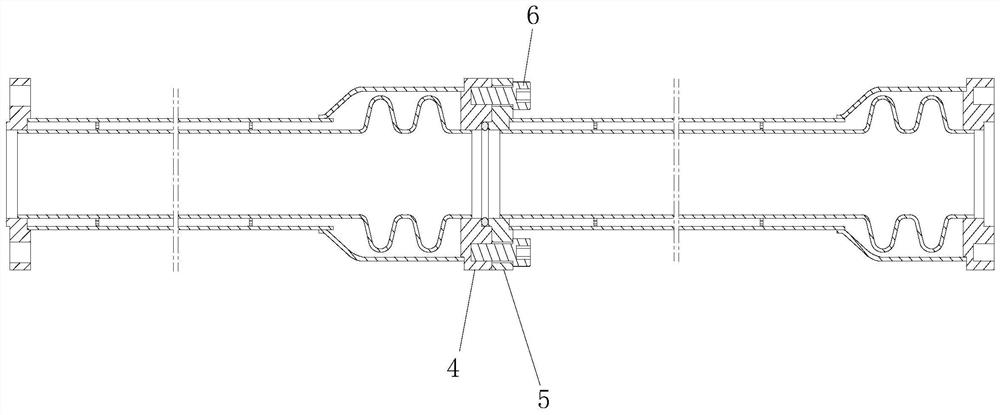

[0079] Figure 7 to Figure 10 The third embodiment of the vacuum tube of the present application is shown, which also has basically the same structure as that of the first embodiment, the main difference being that the third embodiment of the third embodiment is provided with two first rings at the third end of the inner tube 1 In addition to 101, two second rings 102 are provided at the other end of the inner tube 1, that is, the fourth end.

[0080] The second ring 102 has the same structure as the first ring 101 , and is also a radially outwardly convex structure integrally formed on the tube wall of the inner tube 1 and surrounding the periphery of the axis of the inner tube 1 .

[0081] When the length of the vacuum tube is relatively large, it will be difficult to fully absorb / compensate the telescopic deformation of the inner tube if only one or two rings are provided on the inner tube 2 . Therefore, in this embodiment, four rings—two first rings 101 and two second rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com